Spray head

A sprinkler head and nozzle technology, applied in the sprinkler field, can solve the problems of high manufacturing cost, complex sprinkler structure, etc., and achieve the effect of saving space

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

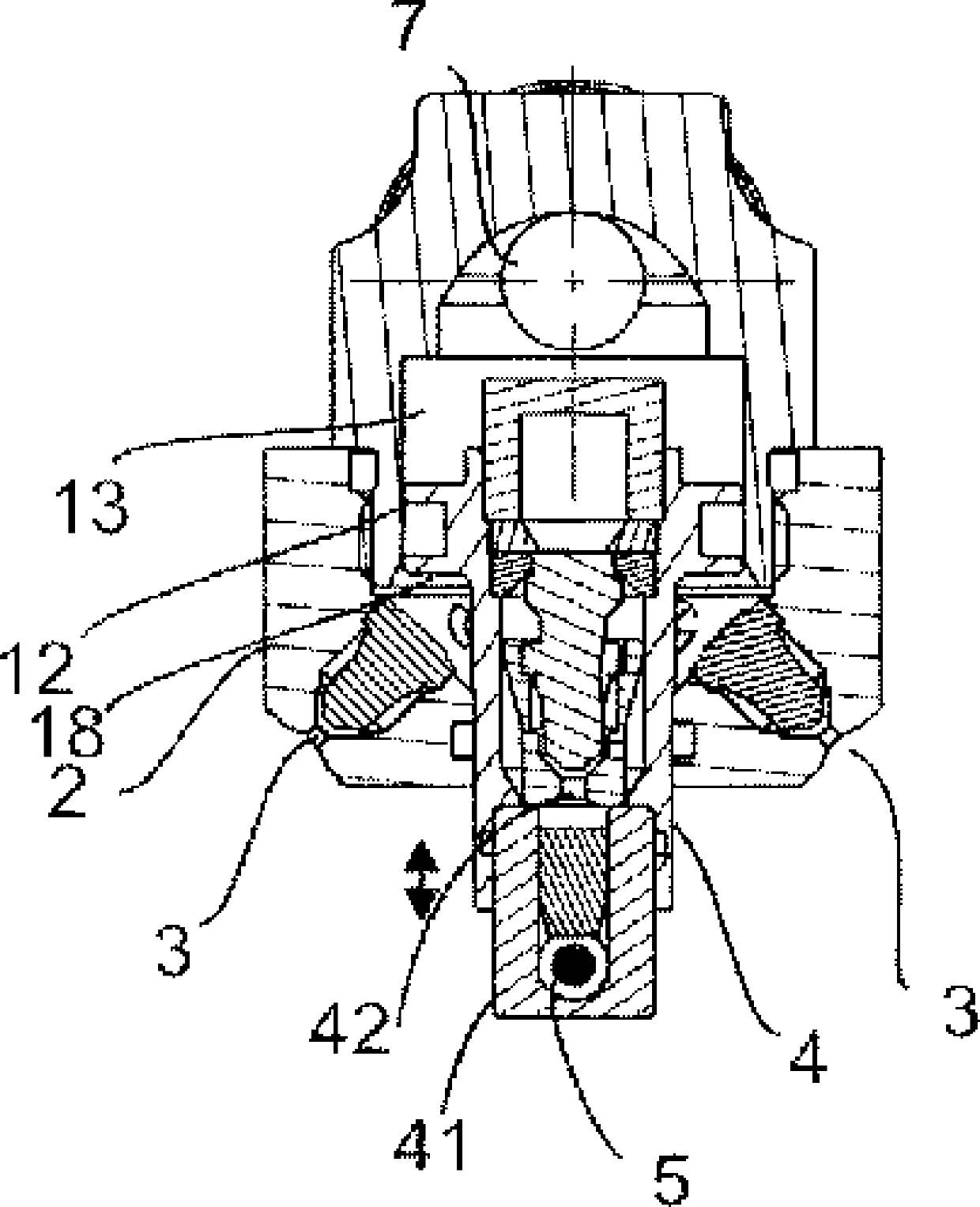

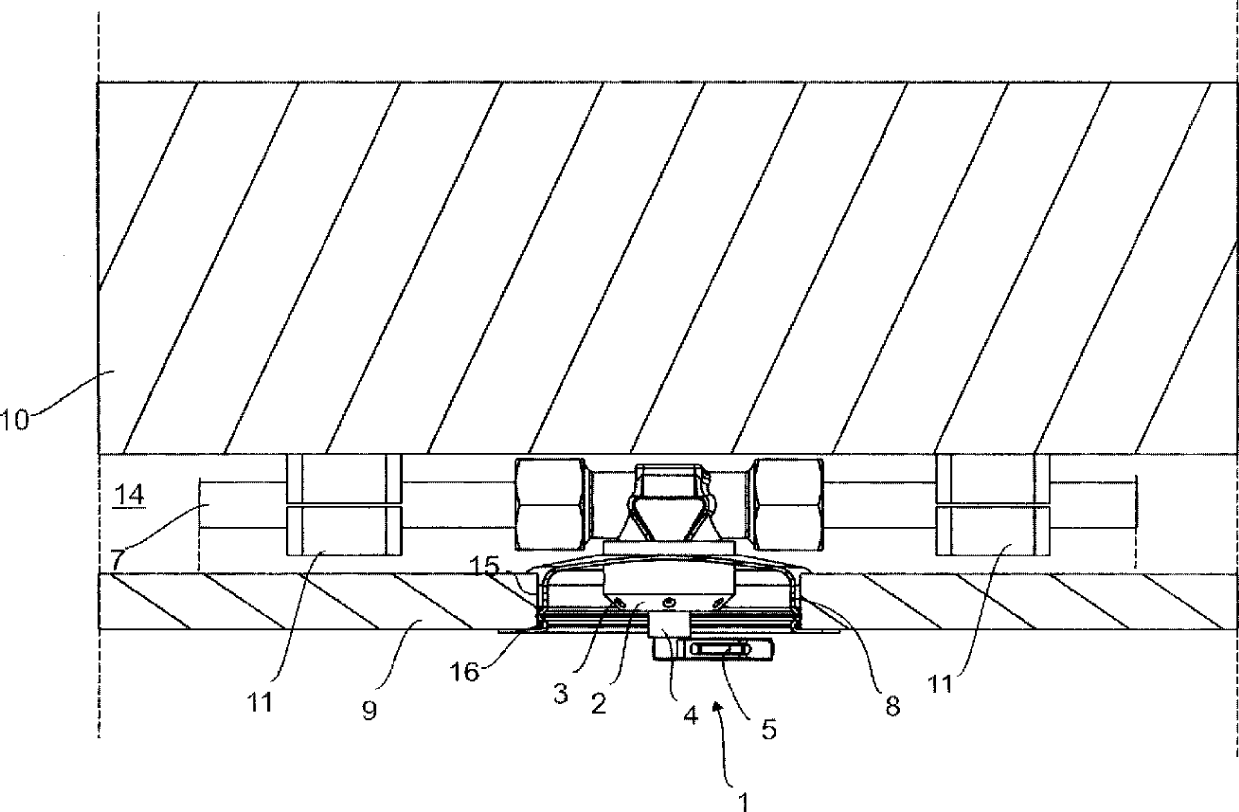

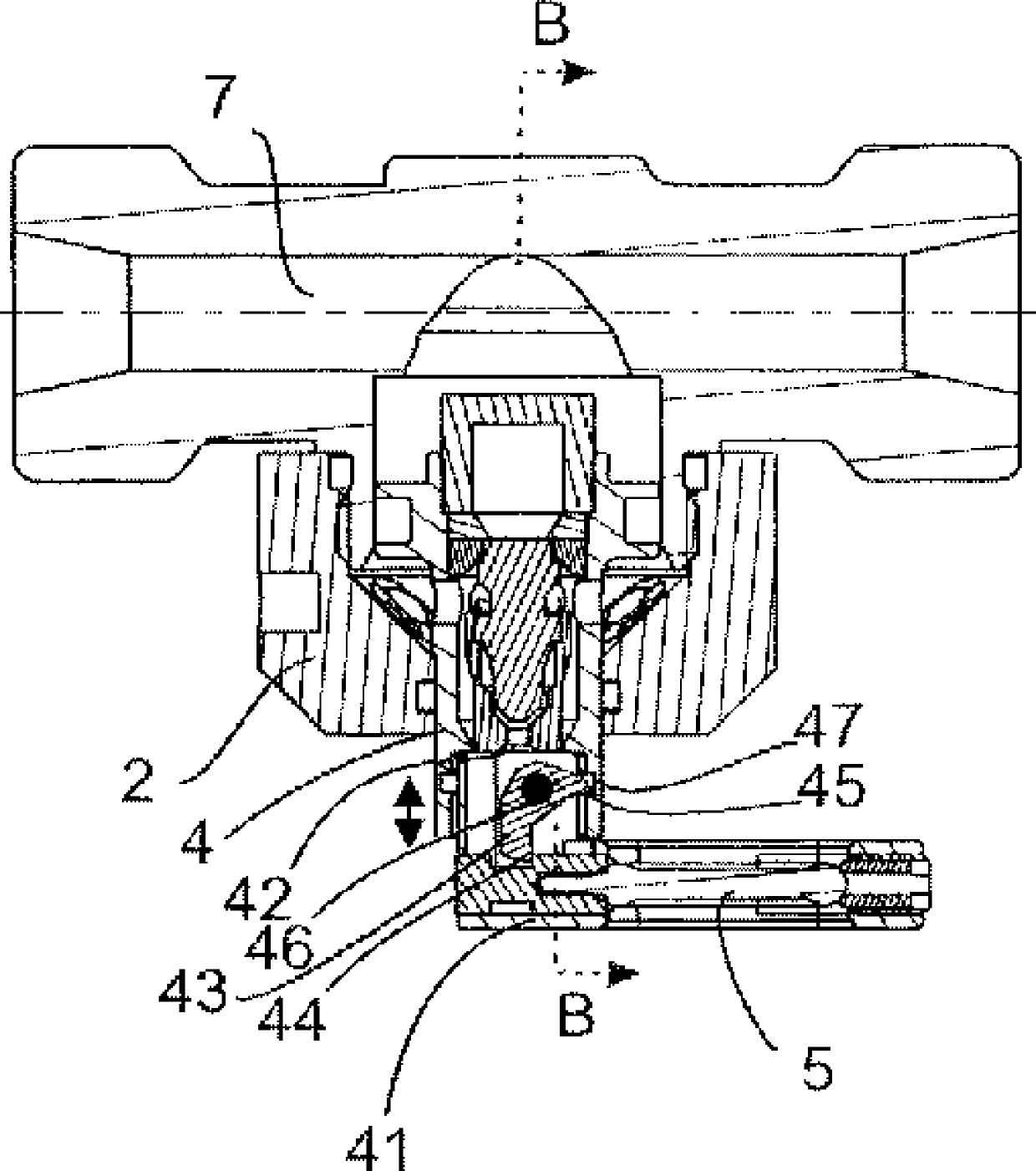

[0015] figure 1 A spray head 1 according to the invention is presented, which is arranged on a fixed surface 10, such as on a ceiling, a wall or a corresponding surface. Lines 7 , or corresponding medium conduits, are provided to the spray head, through which the medium to be sprayed is brought to the spray head. The pipeline is fixed to the fixing surface 10 by fastening means 11 . The wall or ceiling structure comprises a cover plate 9 , such as a suspended ceiling, at a distance from the fixed surface, in which case a space 14 remains between the fixed surface 10 and the cover plate 9 for the pipeline 7 . A hole 15 is formed in the cover plate 9 . A mounting box 8 is arranged in the hole 15, the walls and base of which box extend inwards from the hole 15, ie towards the pipeline 7 in the figure. The protective device 6 is arranged in front of at least one nozzle of the spray head and in front of the trigger element 5 . figure 1 The protective device 6 in the embodiment ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com