Transporting device for tape volume

A transfer device and coil technology, applied in metal processing equipment, metal rolling, manufacturing tools, etc., can solve problems such as poor safety and ease of operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] First of all, the terms "horizontal", "up and down", "left", and "right" in the present invention are all positional relationships based on the drawings, and cannot be construed as limiting the present invention. In addition, the terms "first" and "second" are used for convenience of description, and cannot be construed as limiting the present invention.

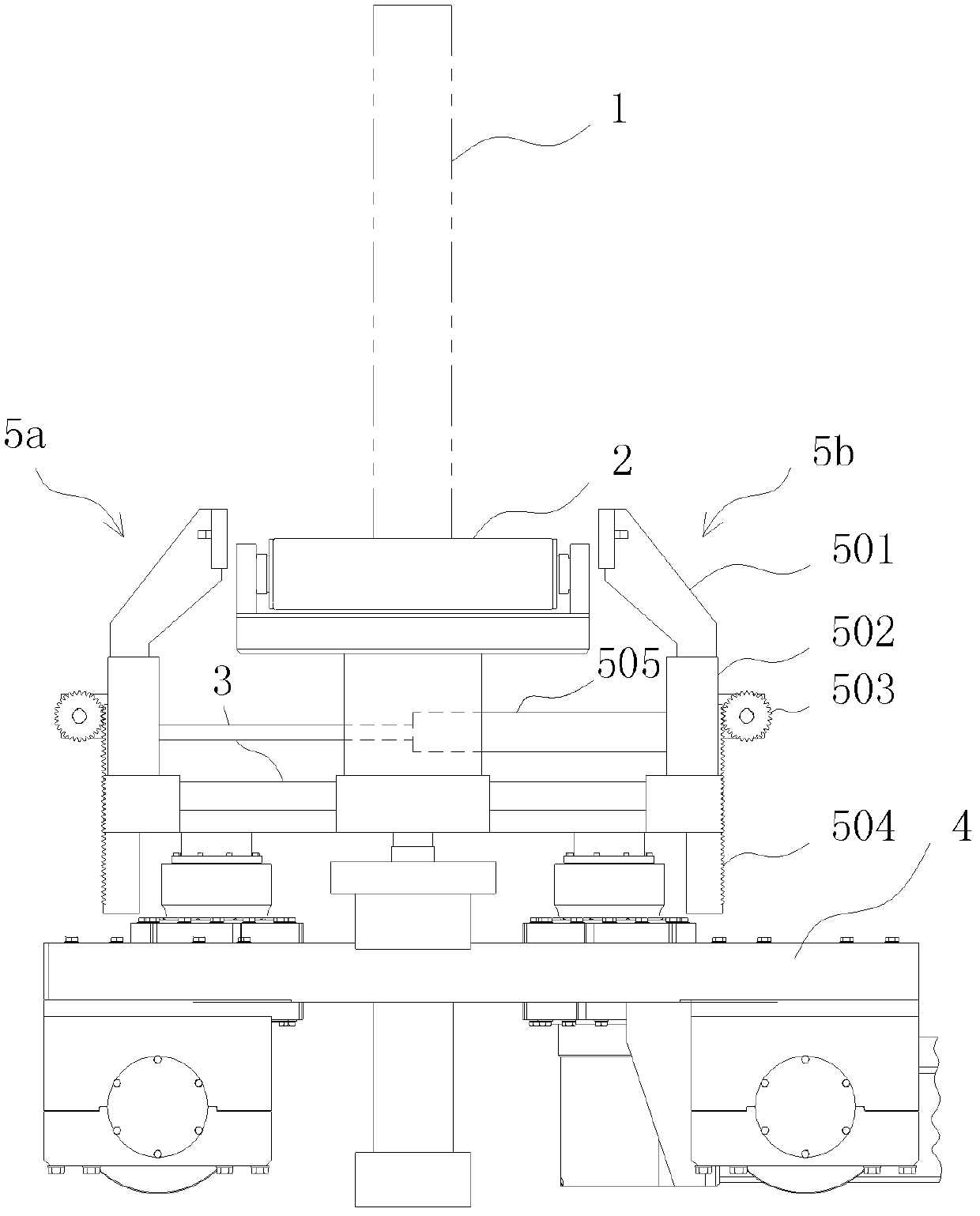

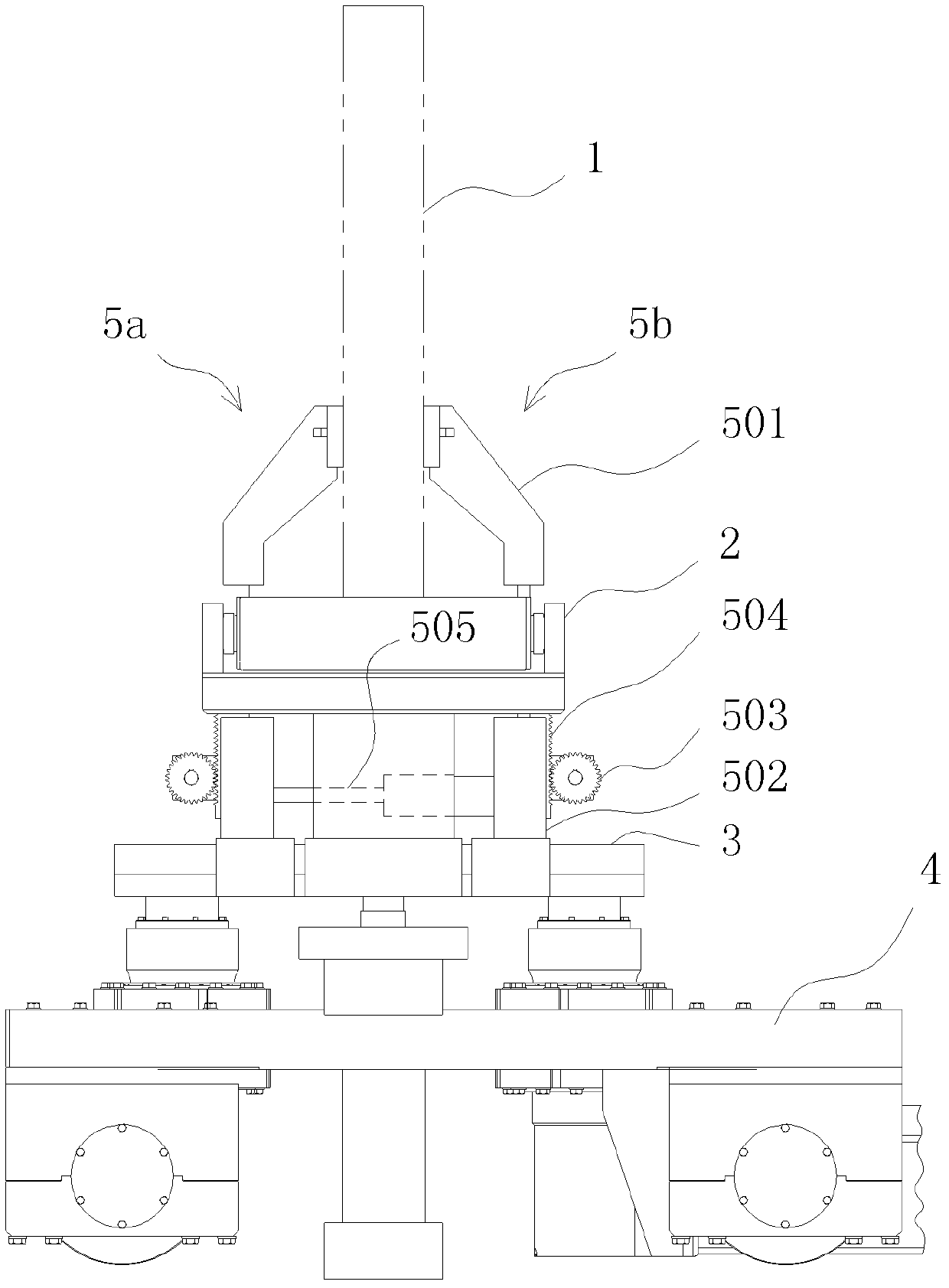

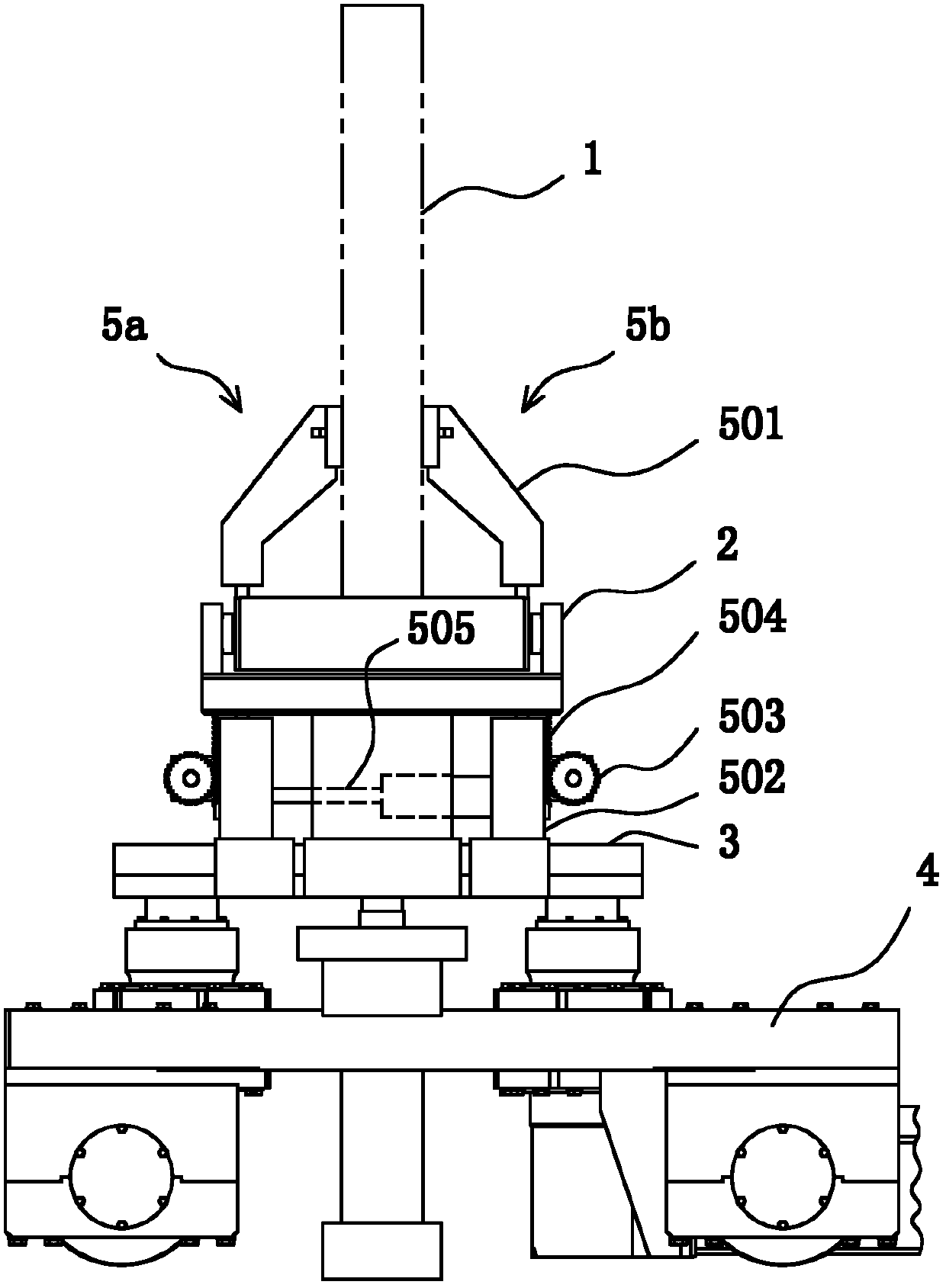

[0014] Such as figure 1 As shown, the left clamping mechanism 5a and the right clamping mechanism 5b have the same structure, and both include a clamping head 501, a sliding seat 502, a gear device 503, and a rack 504. The sliding seat 502 of the roll mechanism 5a and the sliding seat 502 of the right clamping mechanism 5b are connected; wherein, the sliding seat 502 is provided with a transverse T-shaped groove and a longitudinal T-shaped groove, and the transverse T-shaped groove is connected to the T at the end of the supporting seat 3. The type block structure is matched, its longitudinal T-shaped groove is match...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com