Tray box

A pallet box and chassis technology, which is applied in the field of pallet boxes that need to be stacked and transported, can solve the problems of upper pallet box tipping, etc., and achieve the effects of high operating efficiency, good anti-tipping performance, and good strength

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

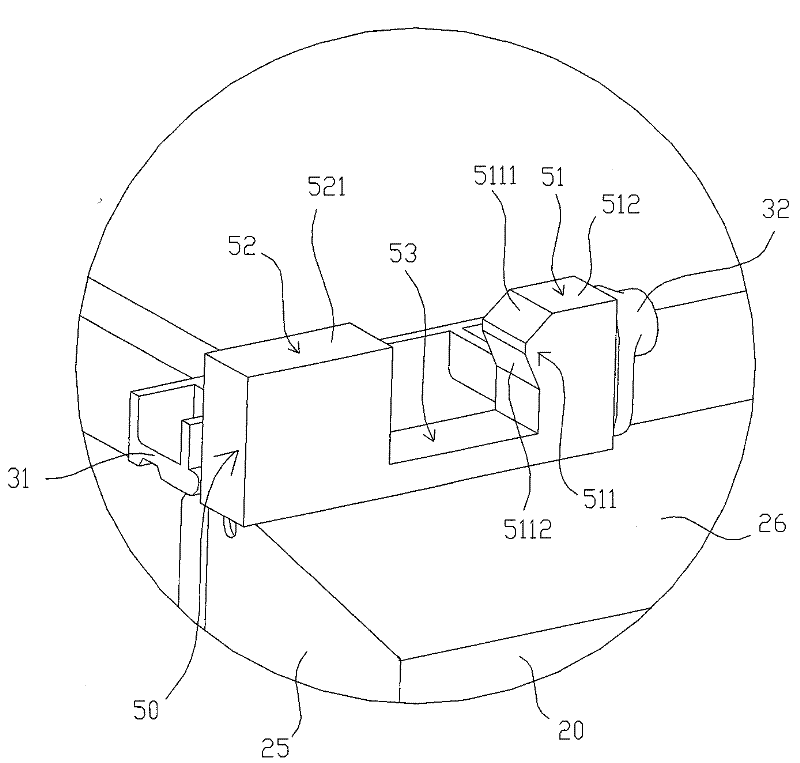

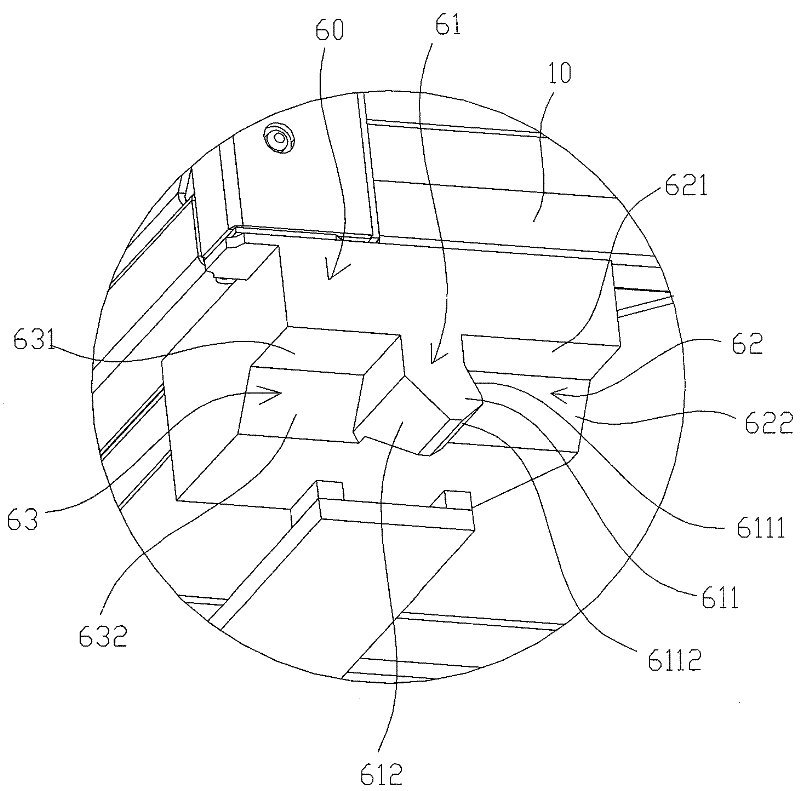

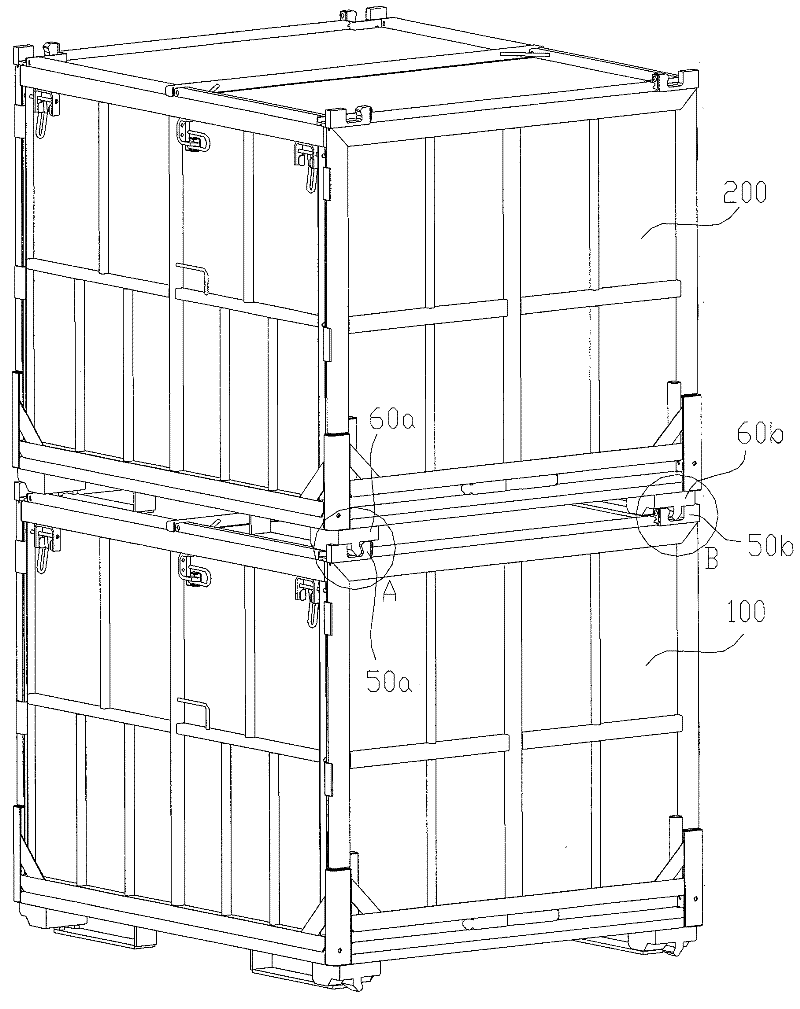

[0042] Such as figure 1 As shown, the overall structure of the pallet box 100 in a preferred embodiment of the present invention is shown. The pallet box 100 at least includes a chassis 10 and four sidewalls 20 , and the four sidewalls 20 are arranged on four sides of the chassis 10 opposite to each other. exist figure 1In the illustrated embodiment, the pallet box 100 can be a collapsible pallet box, wherein the two opposite side walls 20a are rotatably connected to the corner columns 11 of the chassis 10 through their side uprights 25, for example through side uprights The small side column 27 on one side of the lower end of the 25 is connected with the corner column 11, and the bottom beams of the other two opposite side walls 20b are rotatably connected with the corresponding sides of the chassis, and can be connected with the two side walls 20a by the lock 22. The side wall 20 b and the side wall 20 a are clamped in a detachable manner through a limiting member 21 provi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com