Patents

Literature

46results about How to "Improve the efficiency of loading and unloading operations" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Petrochemical unattended loading and unloading line digital twinning intelligent monitoring system and method

ActiveCN112731887AAchieve integrationImprove the efficiency of loading and unloading operationsTotal factory controlProgramme total factory controlDecision controlPetrochemical

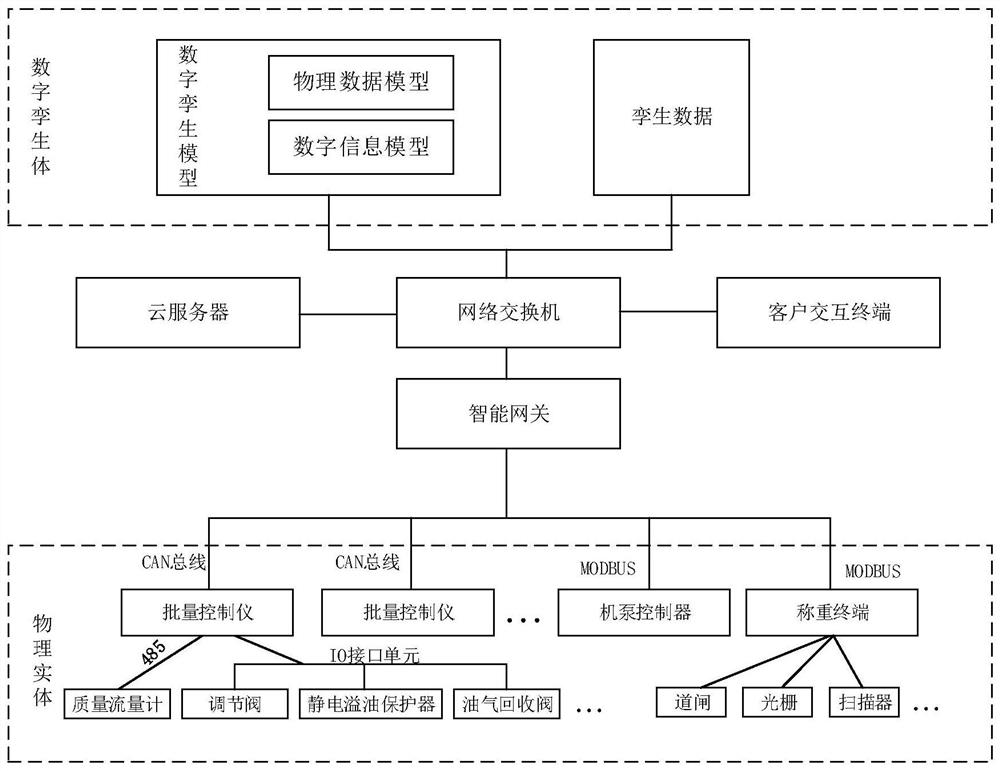

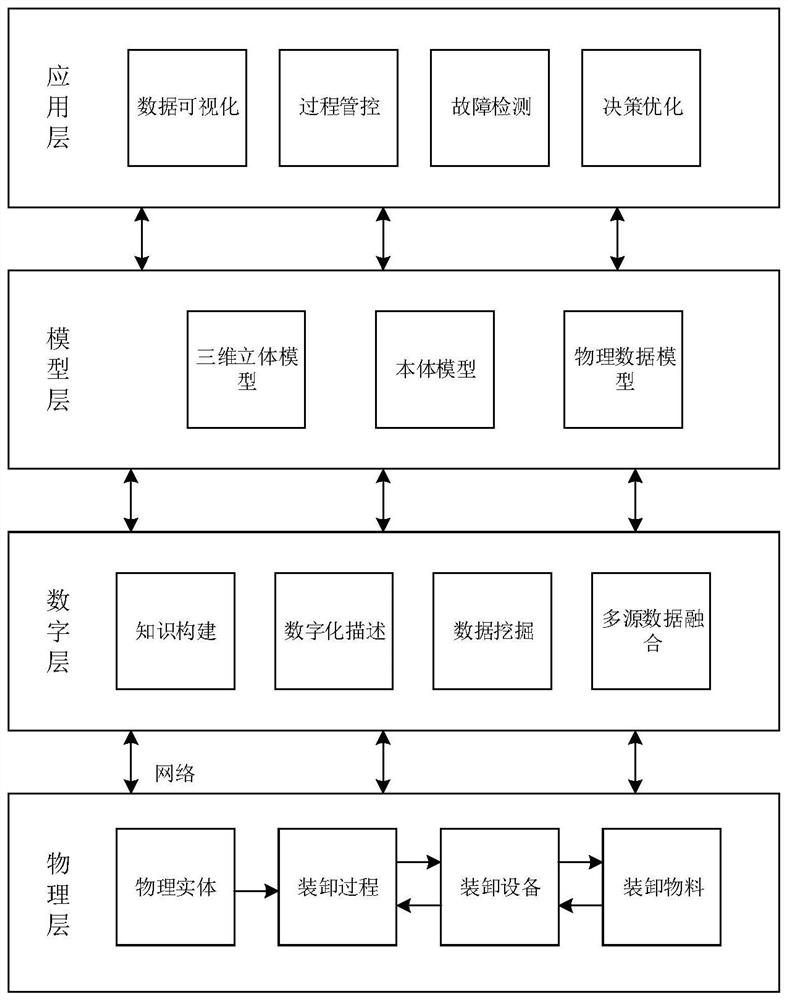

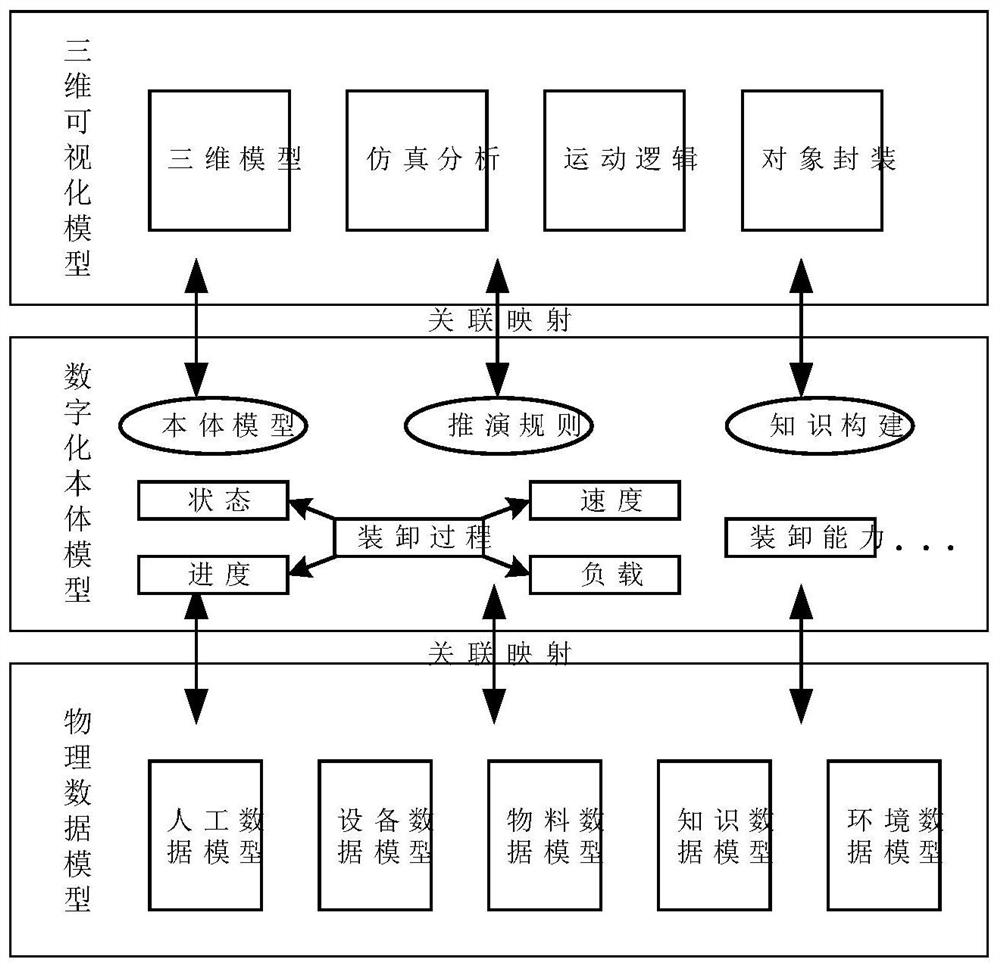

The invention discloses a petrochemical unattended loading and unloading line digital twinning intelligent monitoring system. The system comprises a physical entity, a digital twinning body, an intelligent gateway, a cloud server, a network switch and a client interaction terminal. A digital twinning model is established according to an actual petrochemical loading and unloading line, a loading and unloading line digital twinning body is constructed, the twinning body acquires equipment operation state and process real-time data through an intelligent gateway, twinning data are updated through data fusion, and perception analysis, iterative optimization and decision control are performed by adopting a neural network deep learning algorithm. And meanwhile, the equipment operation state is monitored in real time based on the digital twinning model, parameter control optimization is conducted on loading and unloading operation, and fault prediction and maintenance are conducted on the whole loading and unloading line. The problems that an existing loading and unloading line is low in efficiency, low in visualization degree, poor in man-machine interaction capacity, weak in equipment coordination capacity and the like are solved, and the monitoring real-time performance, the operation efficiency and the equipment safety of the loading and unloading line are improved.

Owner:NANJING UNIV OF SCI & TECH +1

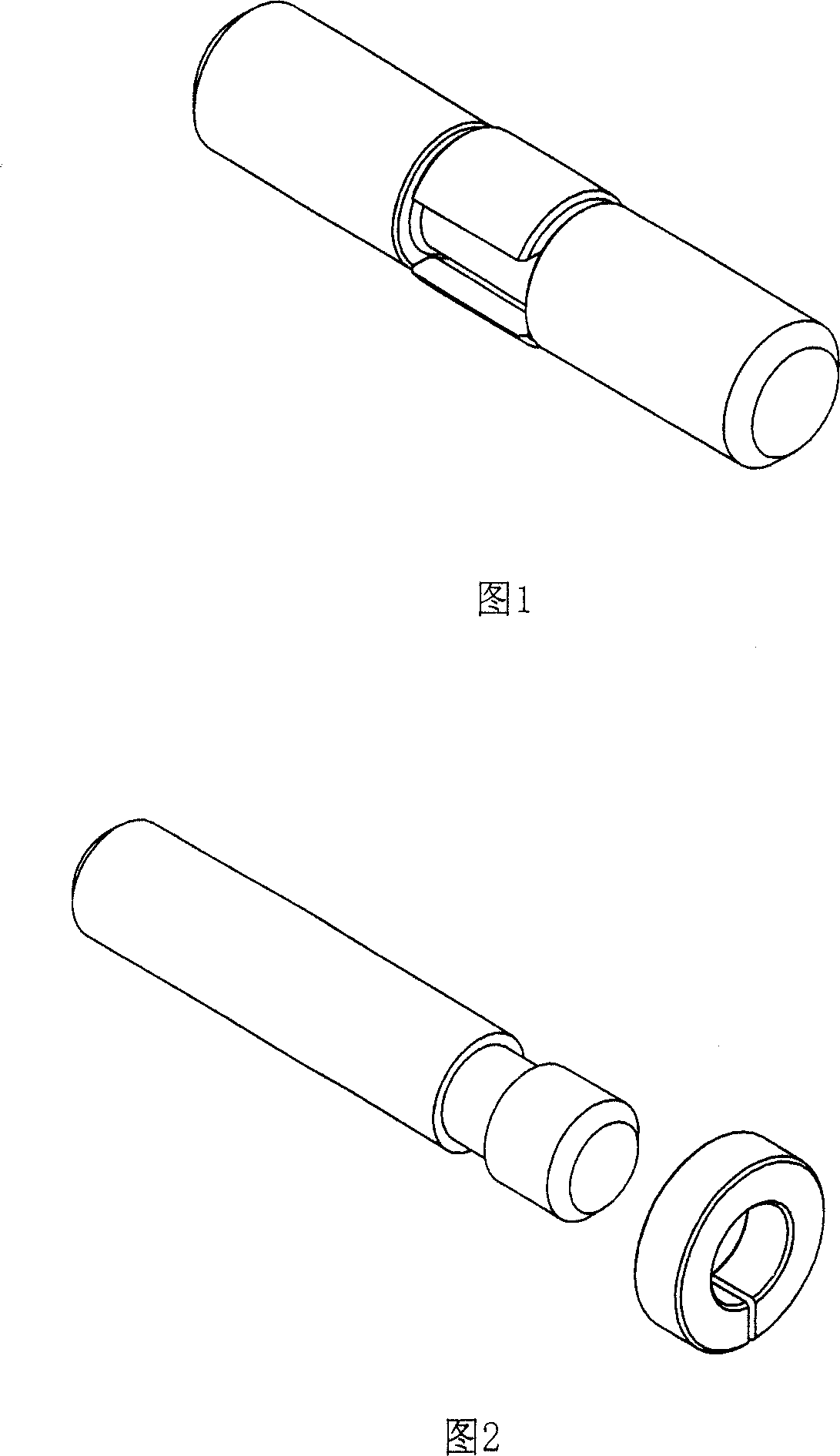

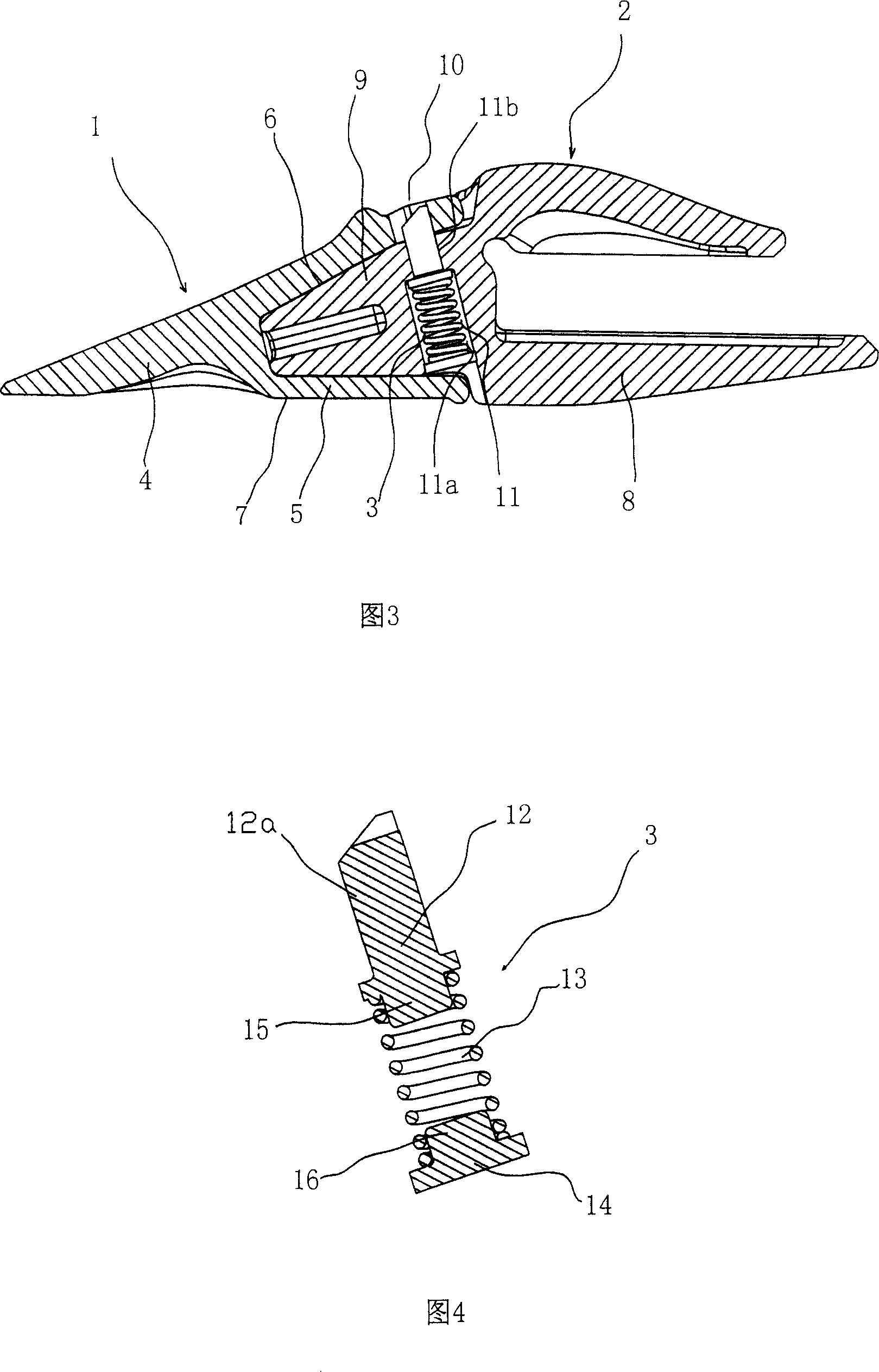

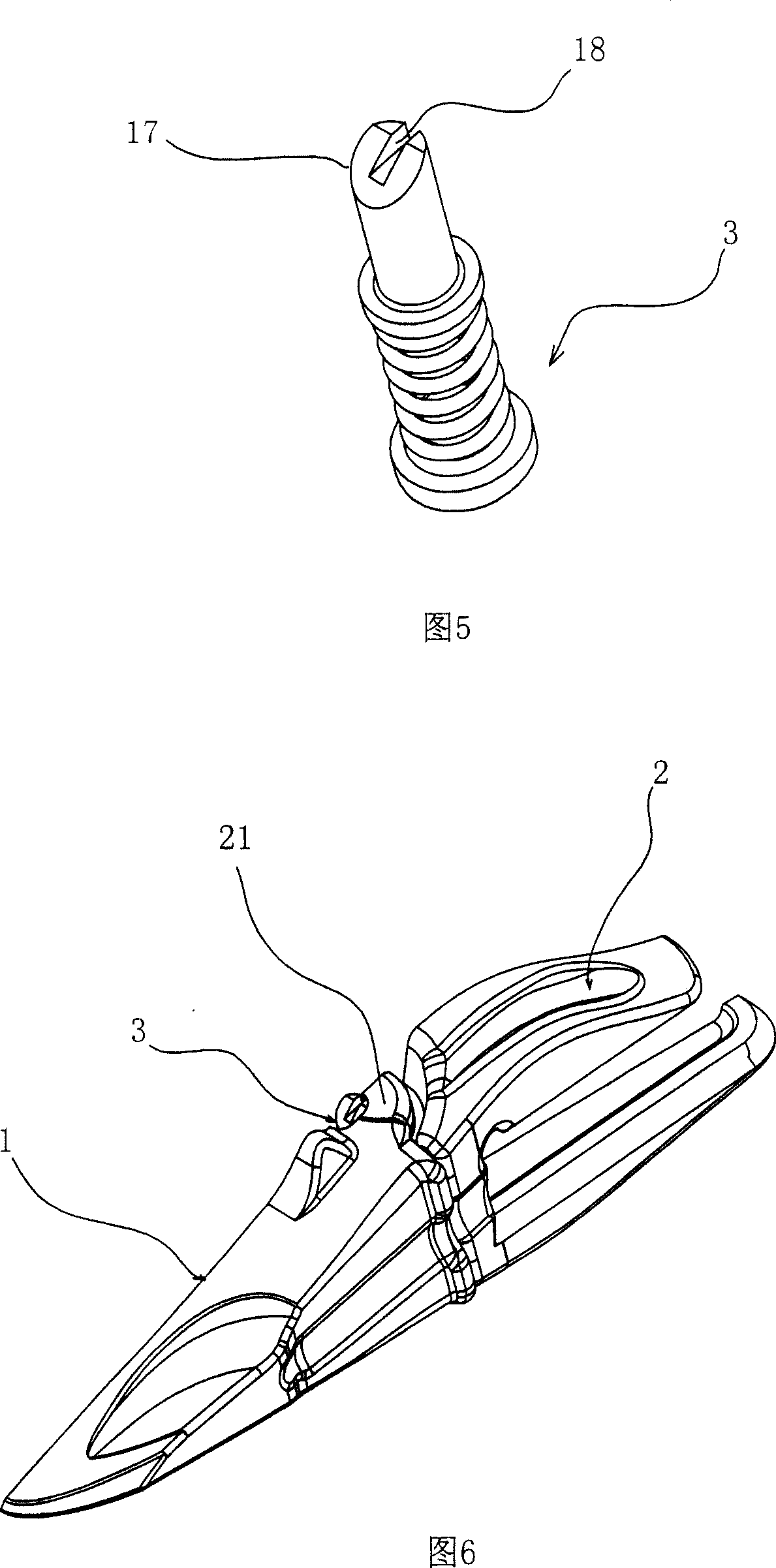

Connecting structure for trolley tine and tine holder

InactiveCN101153497AEmbedded connection is stable and firmFirmly connectedSoil-shifting machines/dredgersEngineeringCavity wall

A link structure between cutting teeth and a tooth holder comprises the cutting teeth, the tooth holder and pins. The tooth holder comprises a tooth holder head on the front part and a tooth holder connecting piece on the rear part, wherein, the tooth holder head on the front part is connected with the front cutting teeth, and the tooth holder connecting piece on the rear part is used for fixing the tooth holder onto the strickle of a bucket. The cutting teeth consists of a tooth tip part and a cutting teeth cavity, wherein, the cutting tooth cavity comprises a cutting tooth inner cavity and a cutting tooth outer cavity, and the tooth holder head is held by the cutting tooth inner cavity, is embedded into the cutting tooth inner cavity and is connected with the cutting tooth inner cavity through pins. The link structure is characterized in that: the elastic pins are arranged inside the pin holes of the tooth holder head, and pin locking holes are correspondingly arranged on the wall of the cutting tooth inner cavity or the extending part of the inner cavity wall to enable adaptation and connection between the elastic pins and the pin locking holes, thereby enabling detachable connection between the cutting teeth and the tooth holder. The link structure can easily fix the cutting teeth and the tooth holder together and enable easy replacement of the cutting teeth, thereby improving the operating efficiency of assembling and disassembling the cutting teeth, reducing the labor intensity of operators, and reducing use cost.

Owner:NINGBO ZHEDONG PRECISION CASTING

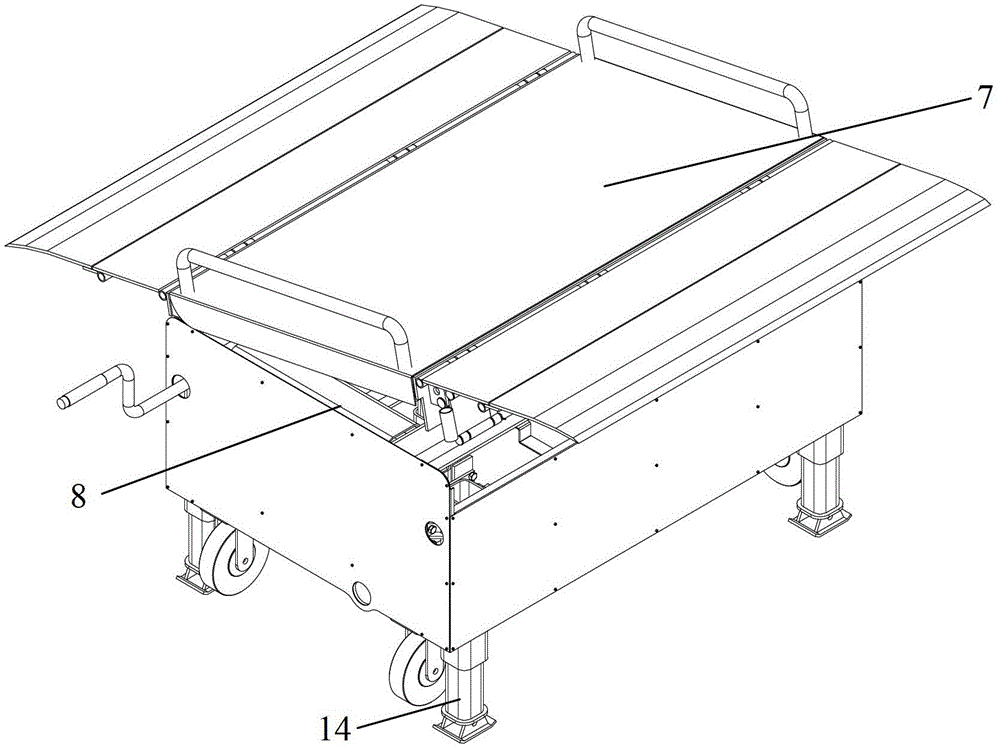

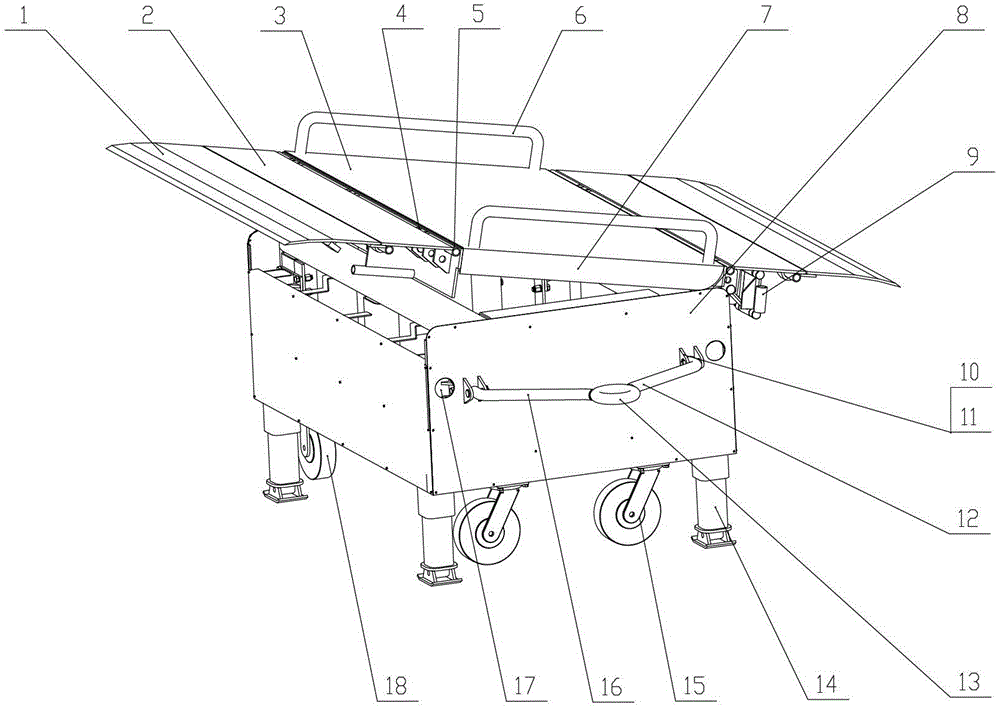

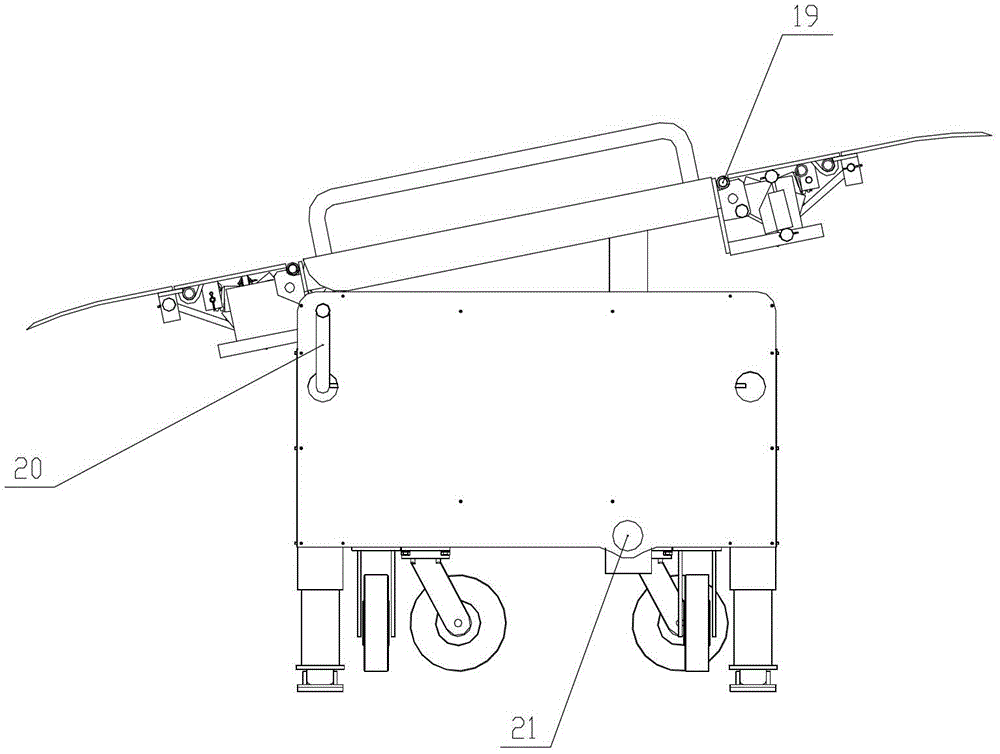

Conveying type carrying vehicle

Owner:JIANGSU ZONP TECH

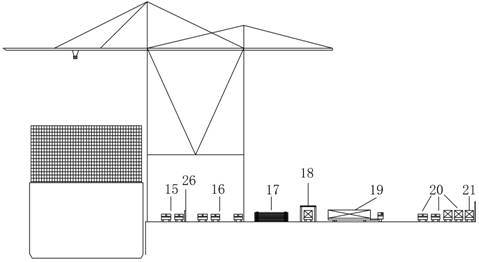

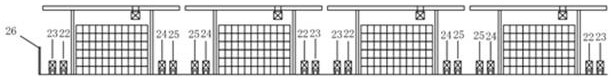

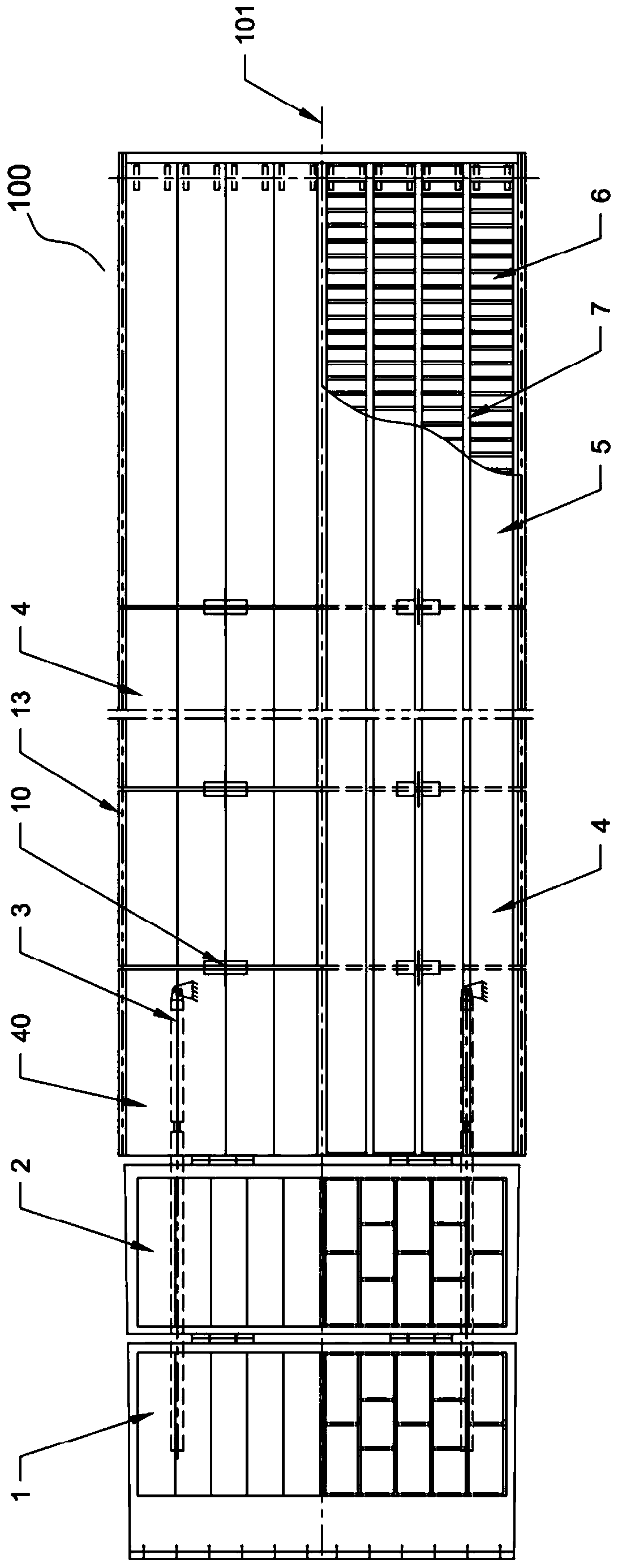

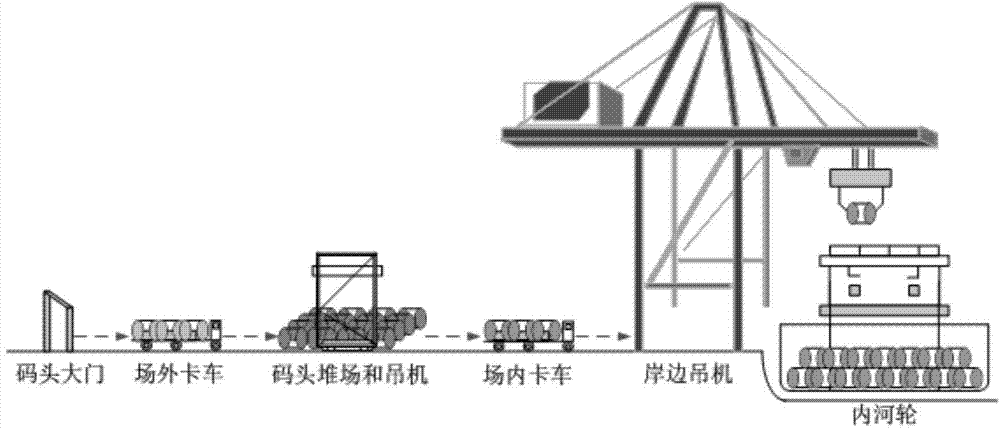

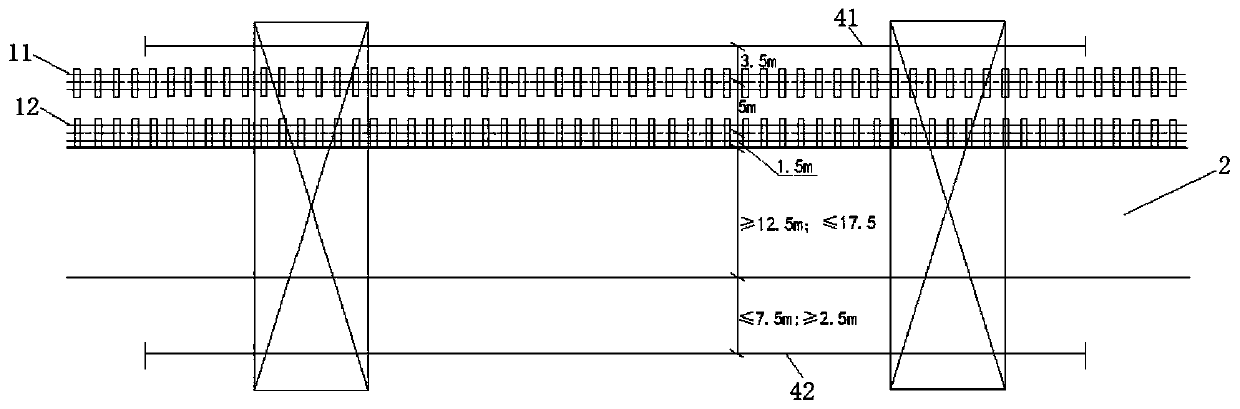

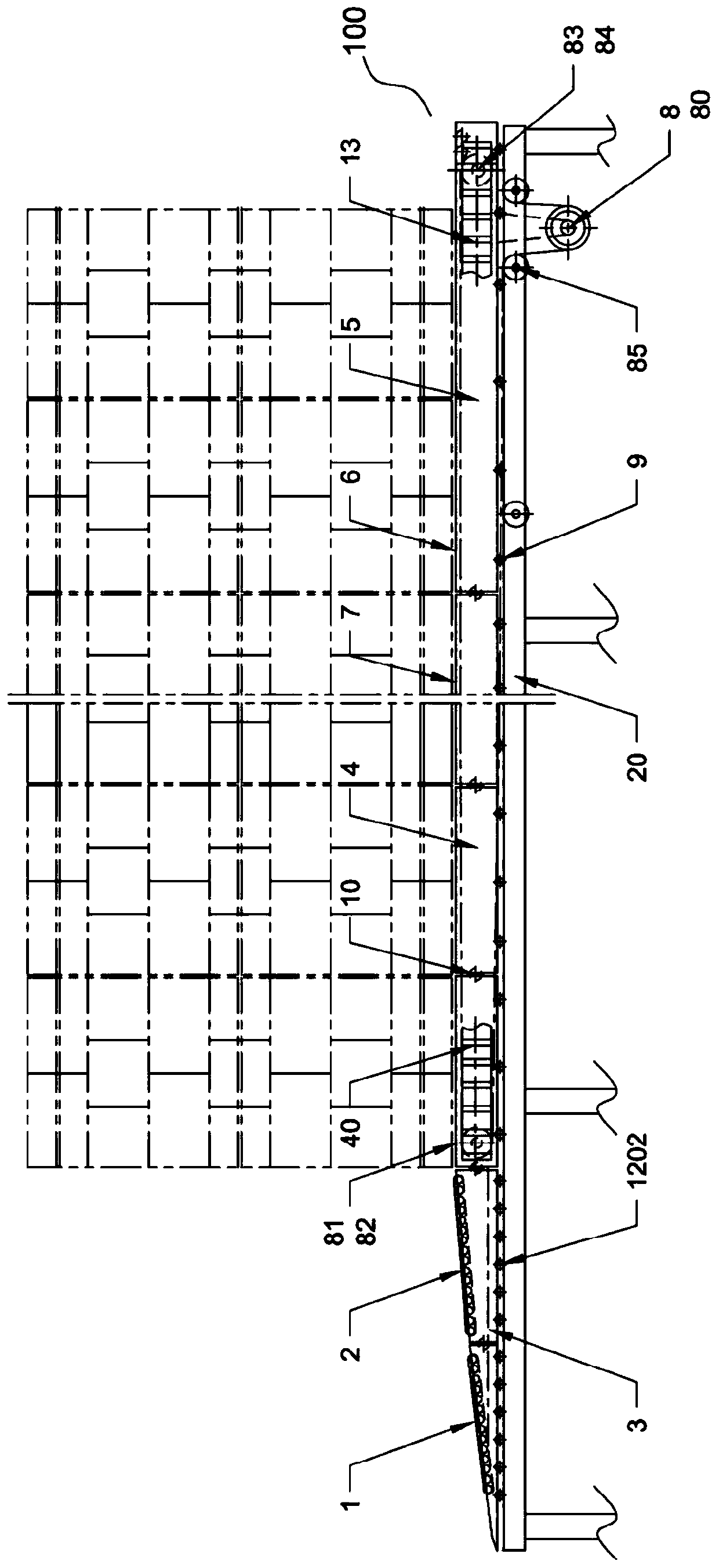

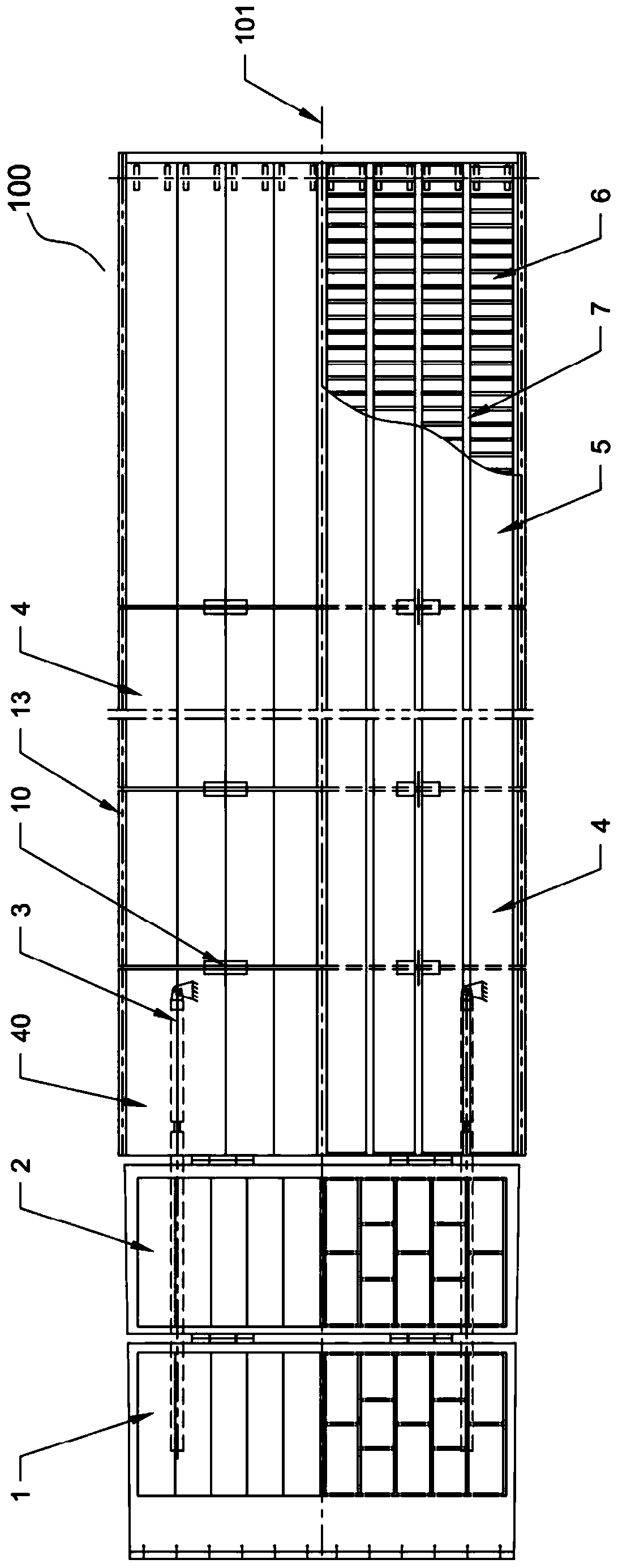

Along-shore type full-automatic container wharf loading and unloading system and loading and unloading process thereof

The invention relates to the technical field of ports, in particular to an along-shore type full-automatic container wharf loading and unloading system. The along-shore type full-automatic container wharf loading and unloading system comprises (1) wharf operation berths, (2) wharf front operation areas, (3) a container automatic storage yard area and (4) facilities behind storage yards, wherein the wharf operation berths are arranged in a full hall manner, and the multiple berths are arranged on a wharf shoreline in a linear manner; the wharf front operation areas are defined between the container operation berths and the container automatic storage yards; the container automatic storage yard area is arranged in parallel and adjacent to the wharf front operation areas and composed of the multiple storage yards arranged in parallel to the wharf shoreline and a plurality of automatic rail cranes arranged in parallel to the direction of the storage yards; and the auxiliary facilities such as wharf entrance and exit gates, a yard parking lot and an auxiliary building area are arranged behind the container automatic storage yards. The method is beneficial to improving the harbor traffic organization and production operation efficiency and improving the intelligent level of a harbor loading and unloading system.

Owner:TIANJIN PORT SECOND CONTAINER TERMINAL CO LTD

Railway port transfer bulk cargo loading and unloading operation method and system

The invention provides a railway port transfer bulk cargo loading and unloading operation method, which comprises: pushing cargo carriages of a grouped rain to a railway transfer carrying platform; loading a single cargo carriage onto a transport automobile by using a railway transport loading and unloading platform, fixing the single cargo carriage onto the transport automobile alone, and transporting the single cargo carriage to a freight yard railway transfer carrying platform designated by a port freight yard according to the attribution of the cargo; and automatically unloading bulk cargo from the freight yard railway transfer carrying platform and completing shipping. According to the method, a track flat plate and a railway are connected by a lifting platform so as to allow the single cargo carriage to be pushed on the track flat plate smoothly and fix the single cargo carriage on the track platform; and the track flat plate on the lifting platform can synchronously rises and falls with the single cargo carriage to load the single cargo carriage onto the transport automobile or unload the single cargo carriage from the transport automobile, and the track flat plate is transported with the single cargo carriage. The loading and unloading efficiency of the railway port bulk cargo combined transportation is increased. One complete 'loading-unloading' or 'unloading-loading'process is avoided, and the combined transportation loading and unloading operation efficiency is increased.

Owner:JILIN MINGPU OPTICAL TECH

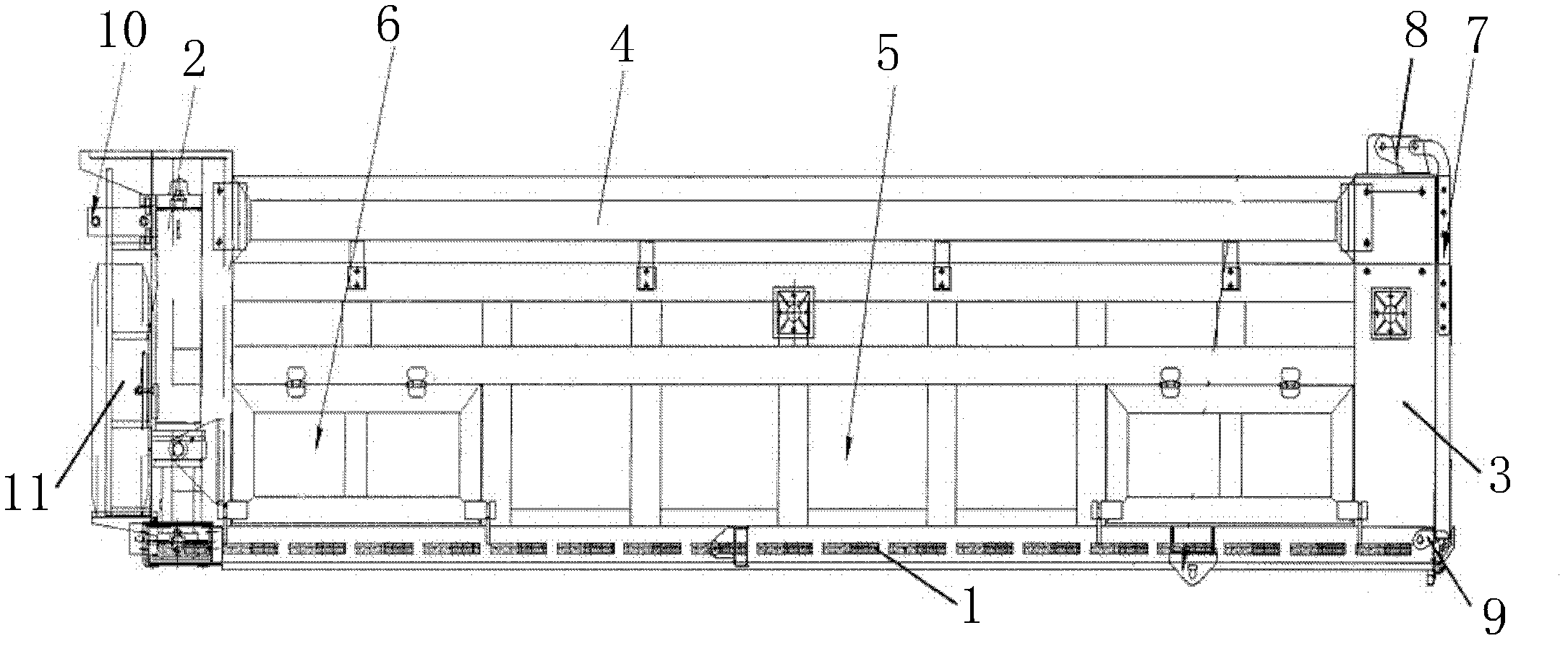

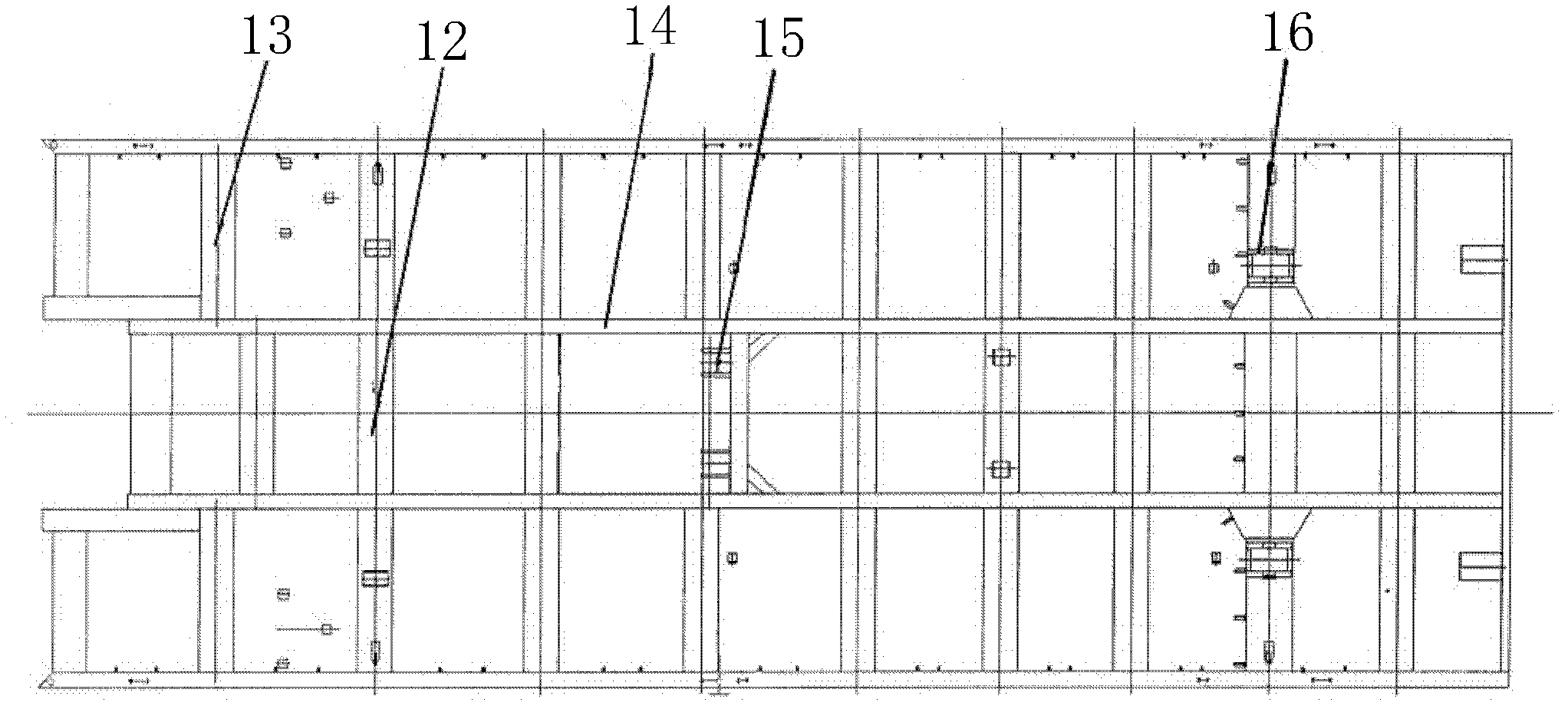

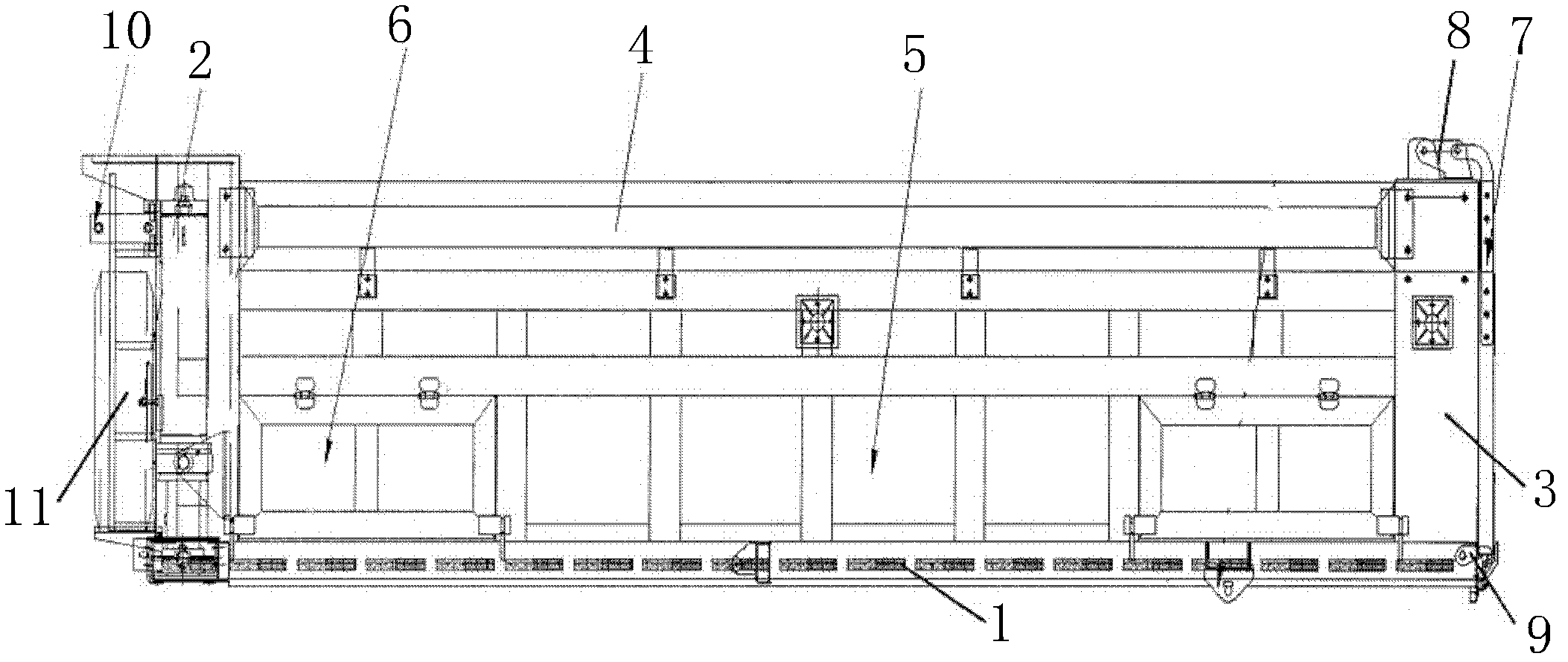

Flexible loading and unloading mobile platform and purposes and application method thereof

ActiveCN110092219AImprove flexibilityContinuous and efficient mobile conveyingLoading/unloadingEngineeringMechanical engineering

The invention discloses a flexible loading and unloading mobile platform and purposes and an application method thereof. The flexible loading and unloading mobile platform comprises a platform foundation component, a platform driving assembly, a bulldozing mechanism and a conveying assembly. The platform foundation component comprises an inclined section plate assembly and a flat section plate assembly which are flexibly connected from front to back in sequence. The flatform driving assembly is connected with the flatform foundation component and a unit cargo integration loading and unloadingoperating vehicle or an underpan, and drives the platform foundation component to reciprocate relative to the unit cargo integration loading and unloading operating vehicle or the underpan. The bulldozing mechanism is arranged below the platform foundation component and used for converting an upper operating surface of the inclined section plate assembly between an inclined surface state and a flat surface state. The conveying assembly is arranged on the flat section plate assembly and reciprocates relative to the flat section plate assembly. When being used, the flexible loading and unloadingmobile platform is arranged on the unit cargo integration loading and unloading operating vehicle or the underpan, a whole vehicle of integrated unit cargoes are loaded and unloaded integrally.

Owner:广州绿茵无垠科技有限公司

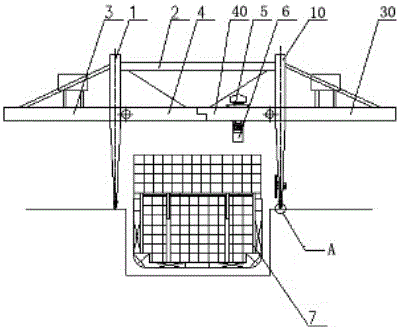

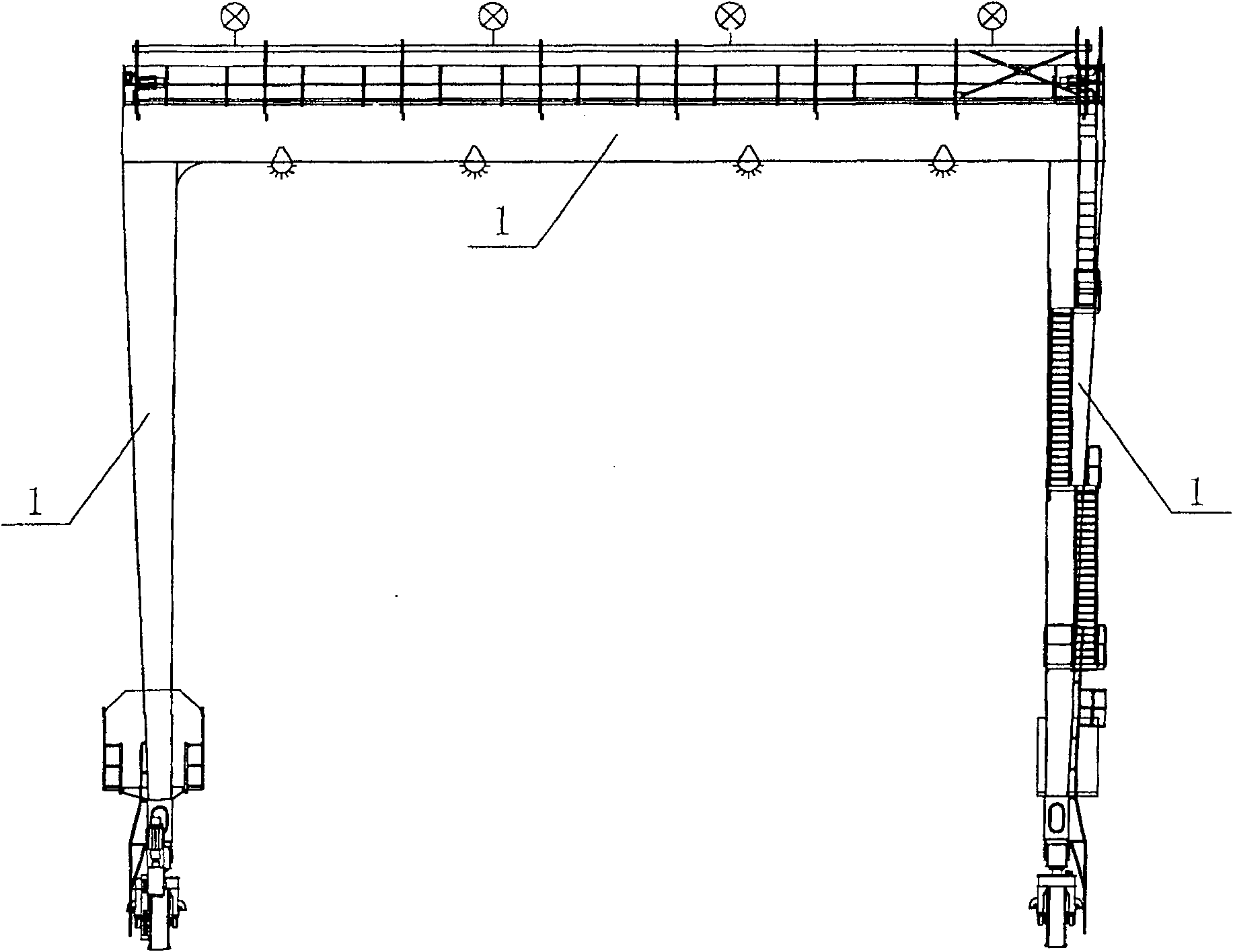

Container crane with double pitching mechanisms and loading and unloading method of container crane

The invention discloses a container crane with double pitching mechanisms. The container crane is composed of a left portal structure, a right portal structure, a cross beam structure, a left rear girder structure, a right rear girder structure, the left pitching mechanism, the right pitching mechanism, a trolley walking mechanism, a lifting tool lifting mechanism, a left cart walking mechanism and a right cart walking mechanism. The cross beam structure is connected between the left portal structure and the right portal structure to form a whole. The left cart walking mechanism and the right cart walking mechanism are correspondingly arranged below the left portal structure and the right portal structure. The left cart walking mechanism and the right cart walking mechanism are arranged on a left rail and a right rail of the two sides of a container ship and can walk along the left rail and the right rail. The double pitching mechanisms are adopted. The invention further discloses a loading and unloading method of the container crane with the double pitching mechanisms. The container crane and the loading and unloading method are applied to loading and unloading work of a container wharf, the defects of a container crane with a single pitching mechanism are overcome, the loading and unloading work efficiency of the wharf can also be greatly improved, and very high economical efficiency and practicability are achieved.

Owner:CCCC THIRD HARBOR CONSULTANTS

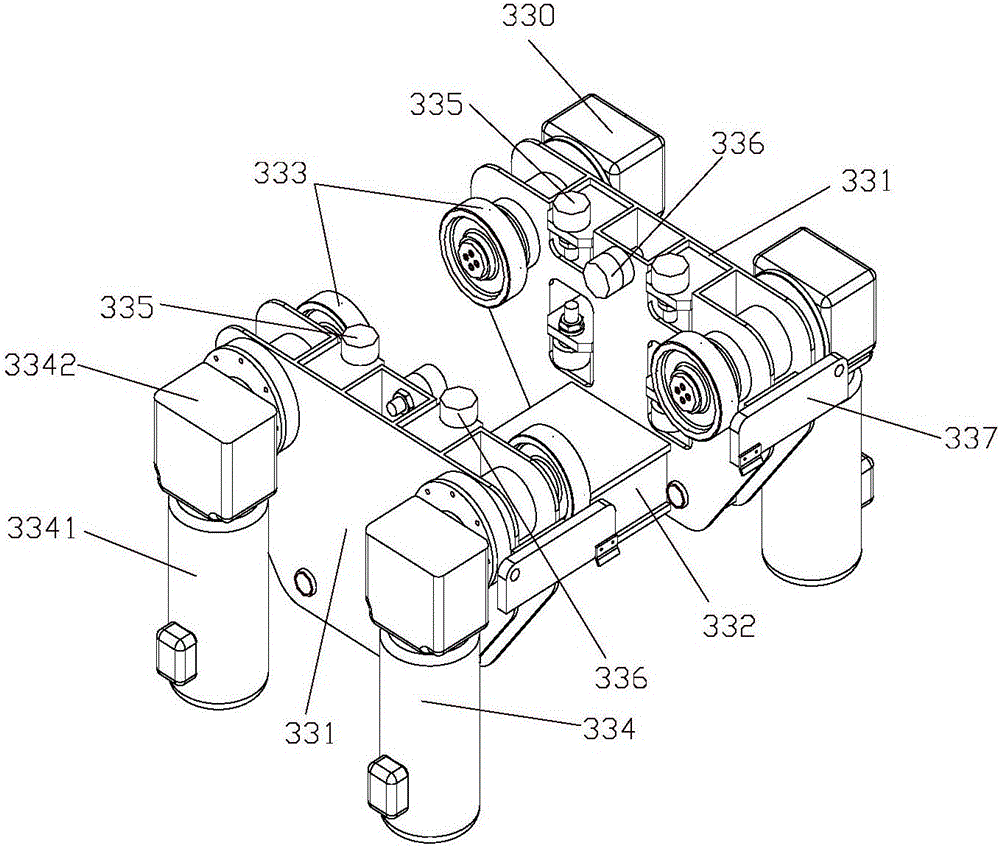

Freight motor car

ActiveCN106364494AImprove the efficiency of loading and unloading operationsMonorailsBogiesVehicle frameBogie

The invention discloses a freight motor car. The freight motor car comprises a freight motor car bogie, a suspension device and an integrated lifting device. The bogie comprises two oppositely arranged car frames, a cross beam fixedly connecting the two car frames, at least two traveling wheels and driving devices. The at least two traveling wheels are arranged on the opposite surfaces of the two car frames correspondingly. The driving devices are fixed to the car frames, are connected with the at least two traveling wheels and are used for driving the at least two traveling wheels to rotate. One end of the suspension device is fixed to the cross beam. The other end of the suspension device is fixed to the lifting device. The bogie moves on a traveling rail, the integrated lifting device lifting and conveying a goods loading device is fixed to the bogie through the suspension device, the goods loading device is transferred, and thus no more car is needed for transferring the goods loading device.

Owner:CRRC YANGTZE CO LTD

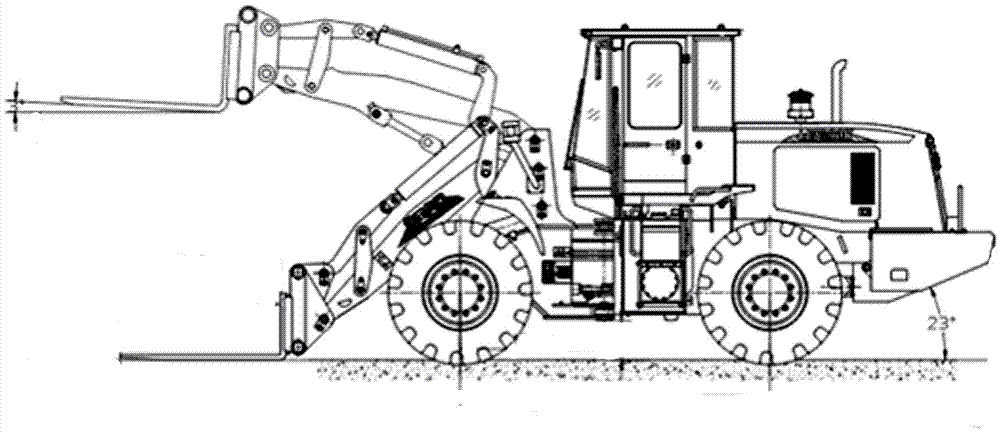

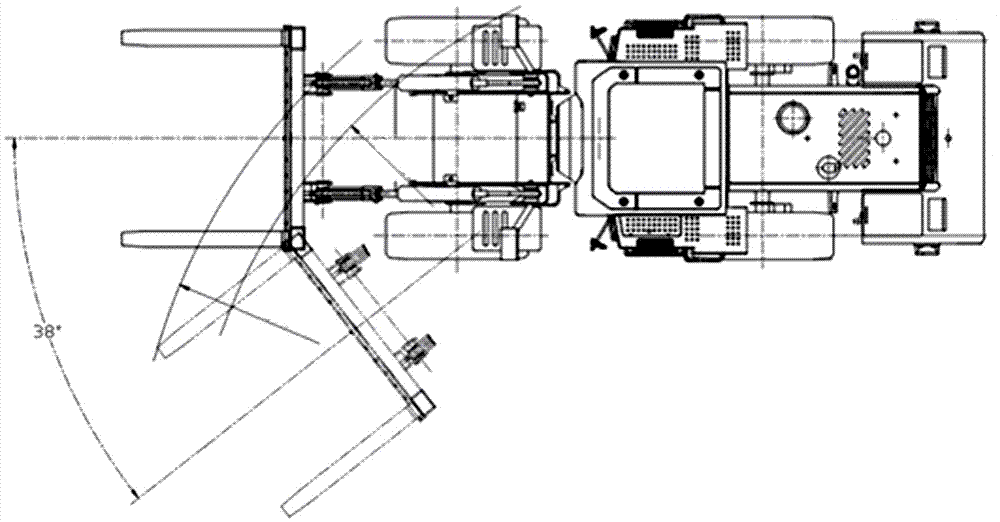

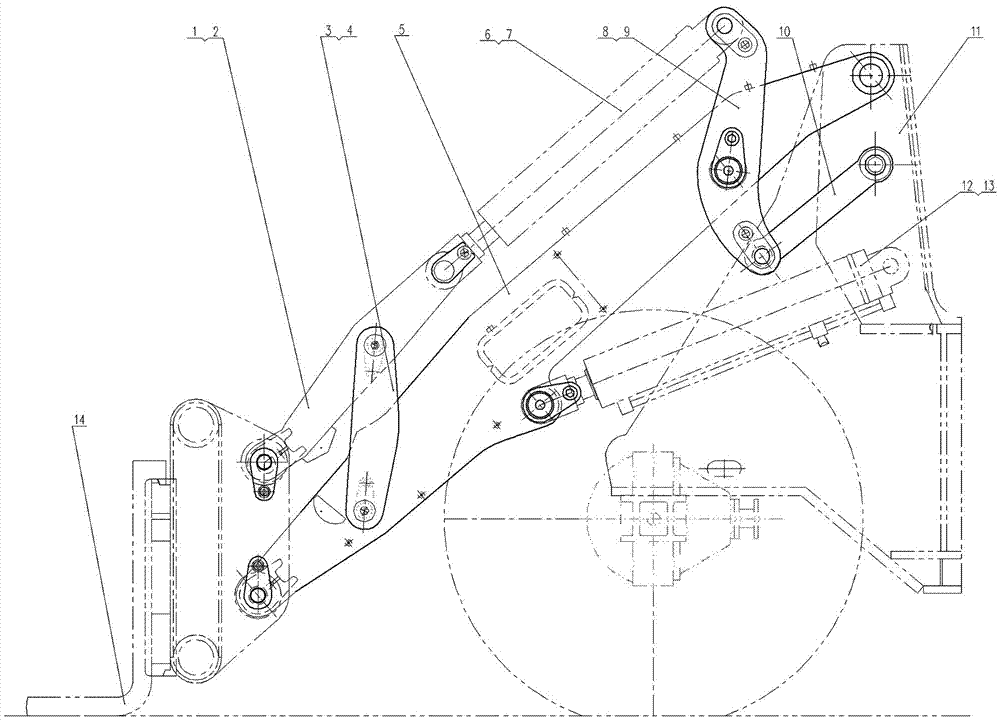

Air-transportable airport loading and unloading forklift truck

The invention discloses an air-transportable airport loading and unloading forklift truck and belongs to the technical field of aviation guaranteeing equipment. The forklift truck comprises a forklift truck main body, the front part of the forklift truck main body is taken as a bracket; a fork lifting device is mounted at the front end of the bracket; and the fork lifting device is a four-degree-of-freedom link mechanism composed of a main arm, a front link part, a front connecting arm part, a main oil cylinder part, a rear rocker arm part, a rear link part, an auxiliary oil cylinder part and a fork assembly at the front end of the main arm. The fork lifting device of the forklift truck provided by the invention can effectively lift the fork assembly, meets the fork lifting capacity of 5 tons of goods with a safety factor above 2.0, and can also be stored when not used so as to facilitate accompanying flight safeguard.

Owner:中国人民解放军空军勤务学院

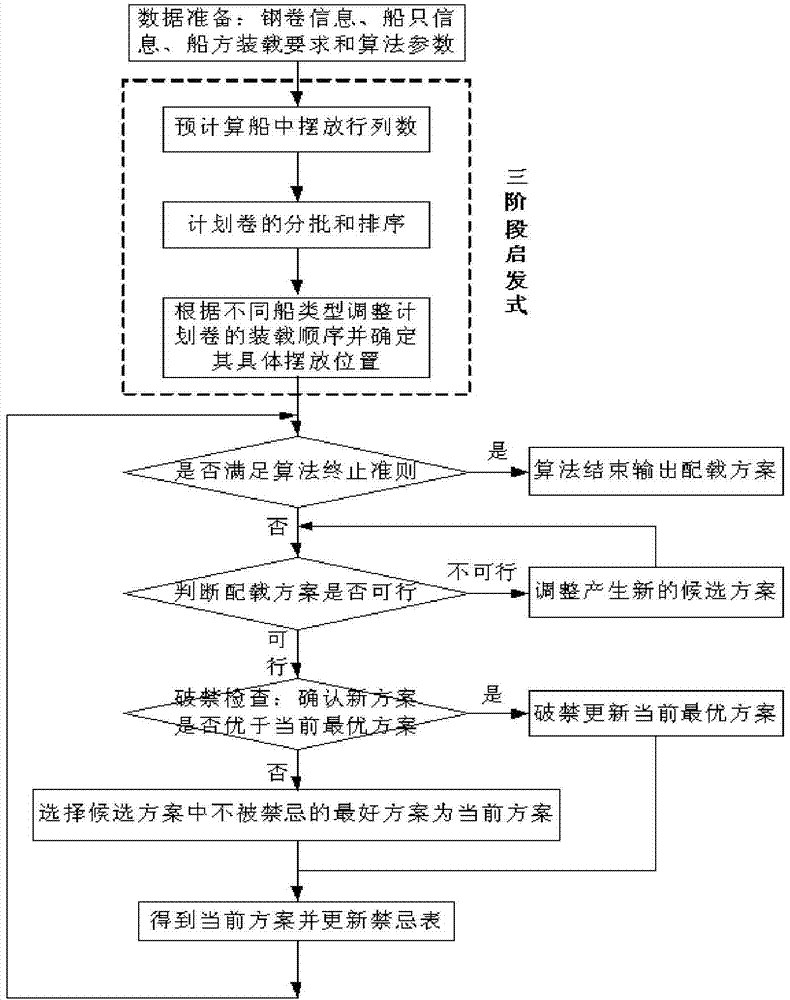

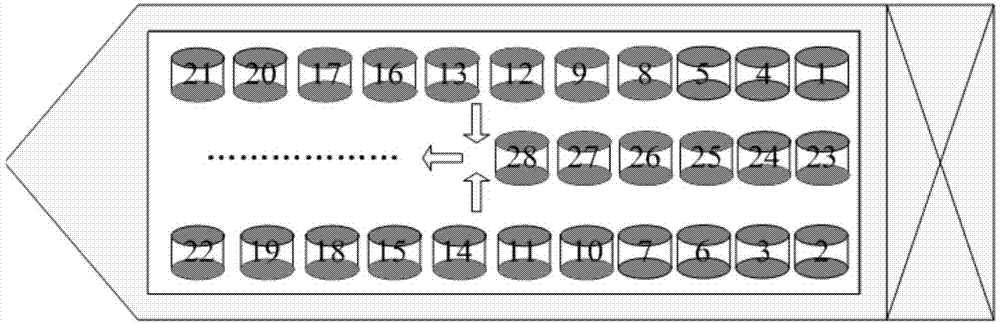

Automatic stowage method for improving stability of water transportation of high board rolls

ActiveCN103500390AReduce workloadImprove the efficiency of loading and unloading operationsLoad accommodationLogisticsComputer terminalTabu search

The invention discloses an automatic stowage method for improving stability of water transportation of high board rolls and belongs to the technical field of information. The automatic stowage method includes the following steps that board roll information, ship information, loading requirement information and algorithm parameter information are read from a database; an initial stowage scheme is generated; whether the generated initial stowage scheme is feasible or not is judged, if yes, stowage indexes are calculated, and if not, the taboo searching method is used for adjusting the stowage scheme; the feasible stowage scheme is optimized. The final stowage scheme is uploaded to the database and displayed on a shore tackle terminal through a network, and ship loading is practically performed through shore tackle operation. According to the automatic stowage method, safety in the loading process and the transportation process is ensured by optimizing and balancing the stowage indexes, accidents are avoided, and therefore extra expenses are avoided. By optimizing the stack transfer stowage indexes, the number of times of stack transfer is reduced, and the working efficiency of wharf loading and unloading is improved. By optimizing the board roll dispersing degree stowage indexes, the wharf shore tackle operation is concentrated, the workloads of workers of shore tackle operation are reduced, and losses of shore tackle equipment are reduced.

Owner:NORTHEASTERN UNIV

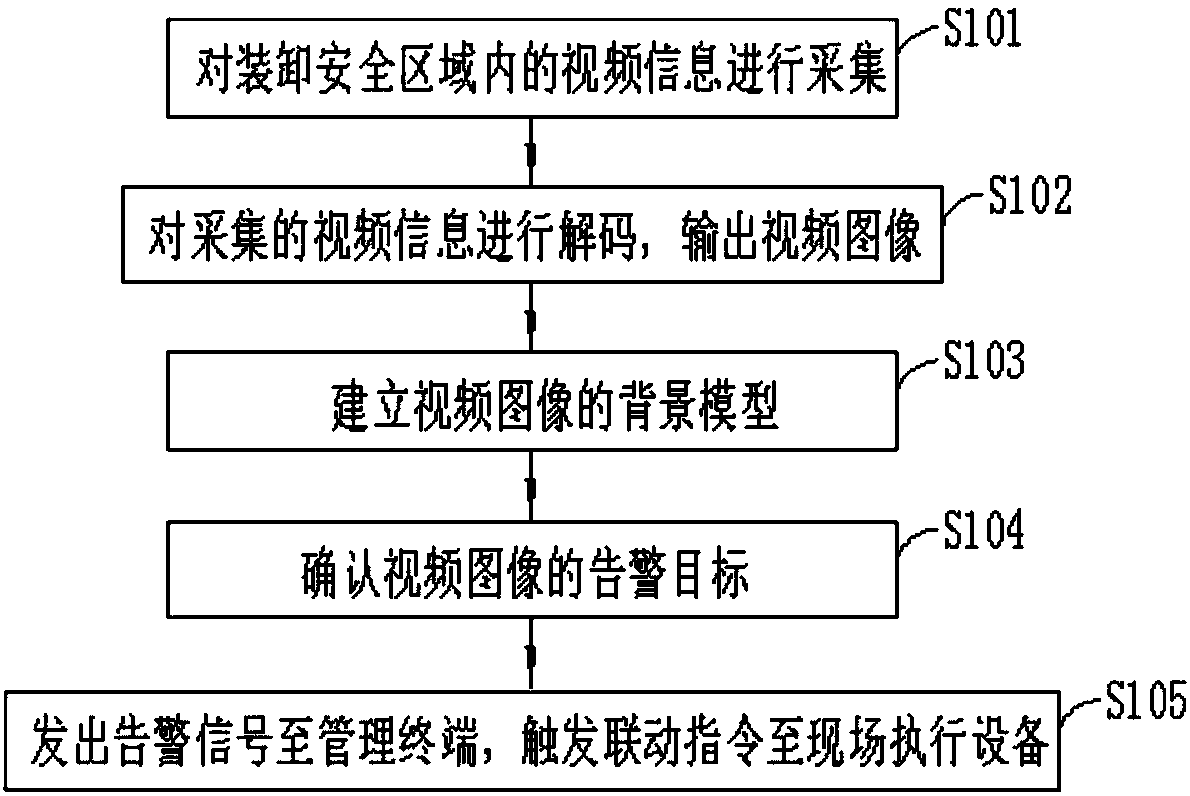

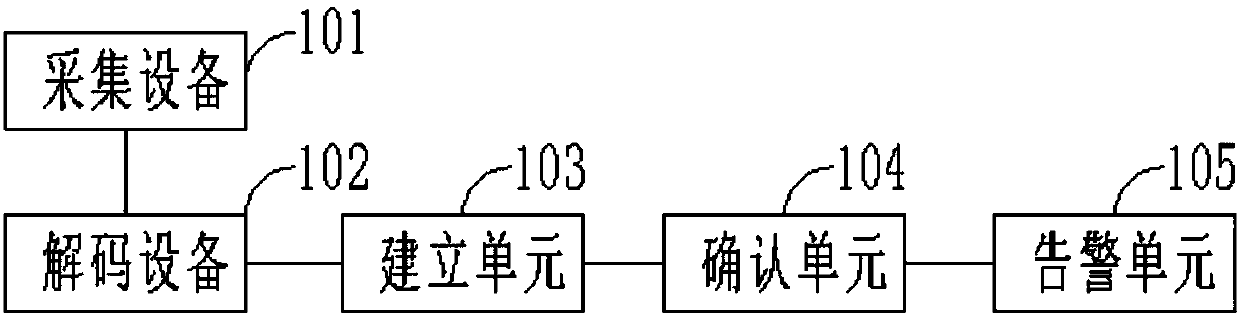

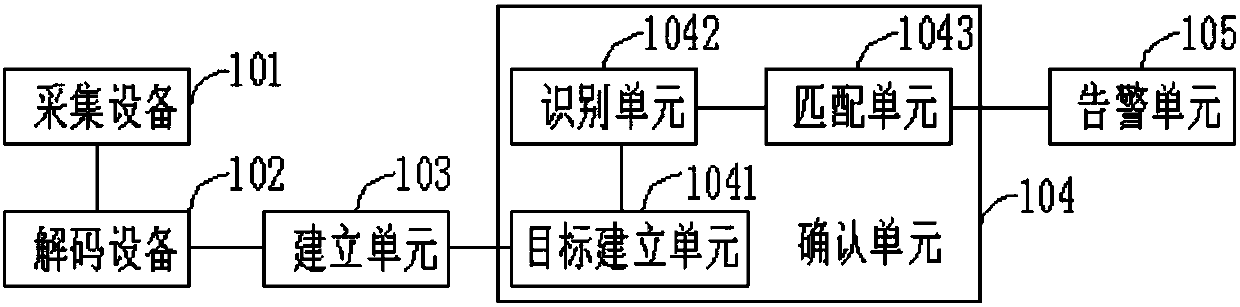

Intelligent loading/unloading execution method and system based on AR

PendingCN107911655AImprove the efficiency of loading and unloading operationsImprove securityImage analysisGeometric image transformationComputer terminalVideo image

The invention belongs to the technical field of the intelligent loading / unloading, and specifically relates to an intelligent loading / unloading execution method and system based on AR. The following technical problem is as follows: an intelligent loading / unloading execution method and system with high security, capable of performing all-around monitoring on loading / unloading process and based on the AR are provided. The adopted technical scheme is as follows: the intelligent loading / unloading execution method based on the AR comprises the following steps: S101, collecting video information ina loading / unloading safety region; S102, decoding the collected video information to output a video image; S103, establishing a background model of the video image; S104, determining an alarm target of the video image; and S105, giving out an alarm signal to a management terminal, and triggering a linkage instruction to field execution equipment. The method and system provided by the invention canbe extensively applied to the transportation field.

Owner:孙云

Novel cargo box of engineering vehicle

InactiveCN102424014AFacilitate cargo unloadingImprove the efficiency of loading and unloading operationsVehicle with tipping movementSpare tireWire rope

The invention discloses a novel cargo box of an engineering vehicle. The cargo box is characterized in that: a front upright and a rear upright are arranged at the two ends of a chassis respectively; an upper side plate and a lower side plate are connected between the front upright and the rear upright; a small door is arranged at each of the two ends of the lower side plate respectively; the rear side plate is arranged on the rear upright through a lifting lug; a hook hangs the rear side plate; a steel wire rope frame and a spare tire frame are arranged on one side of the front upright; the chassis consists of multiple cross beams, side cross beams and longitudinal beams; and an oil cylinder balancing support and an overturning seat are arranged at the middle part of a base and the middle part at the rear end respectively. With the structure, the novel cargo box disclosed by the invention ensures that the cargo loading capacity is increased and guarantees the maximum load of the cargo bearable to the chassis.

Owner:SHANDONG TERRY AUTOMOBILE MACHINE ELECTRICAL

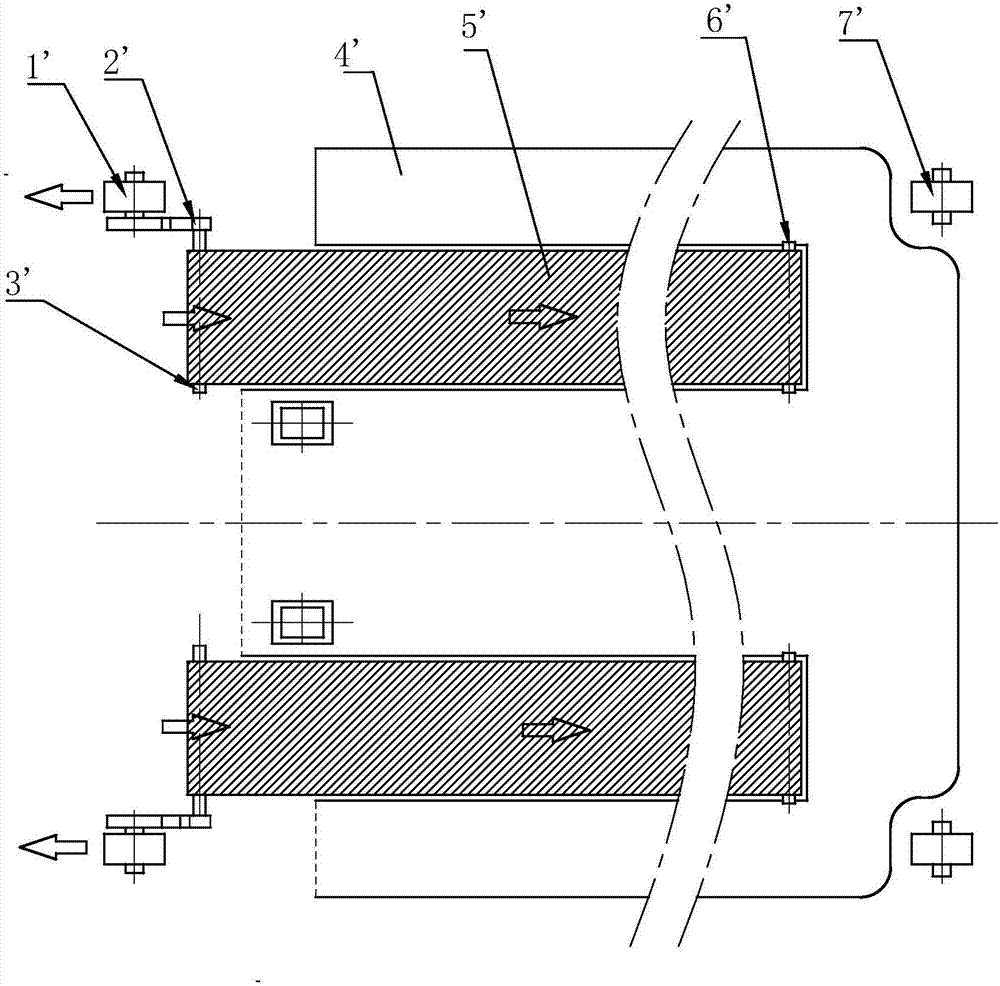

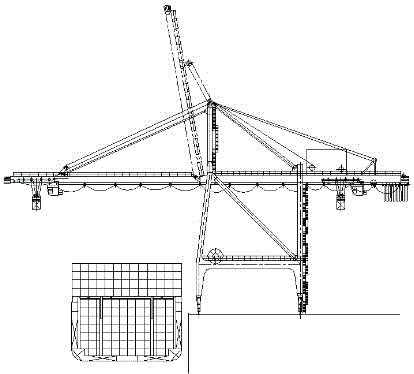

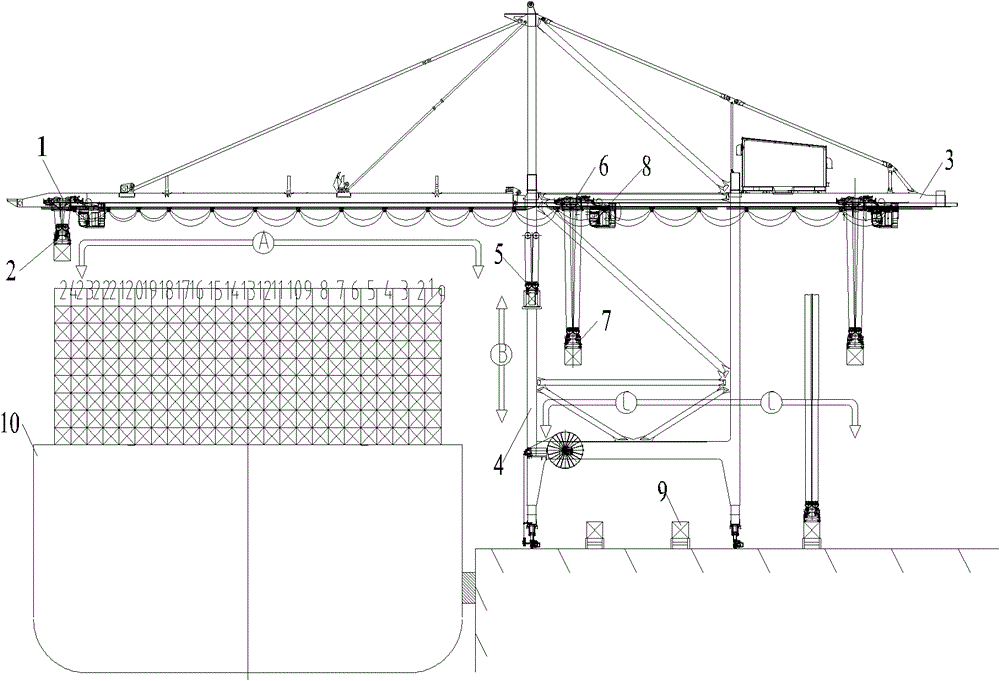

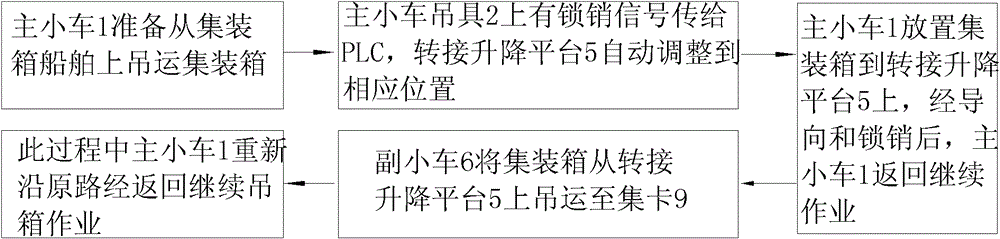

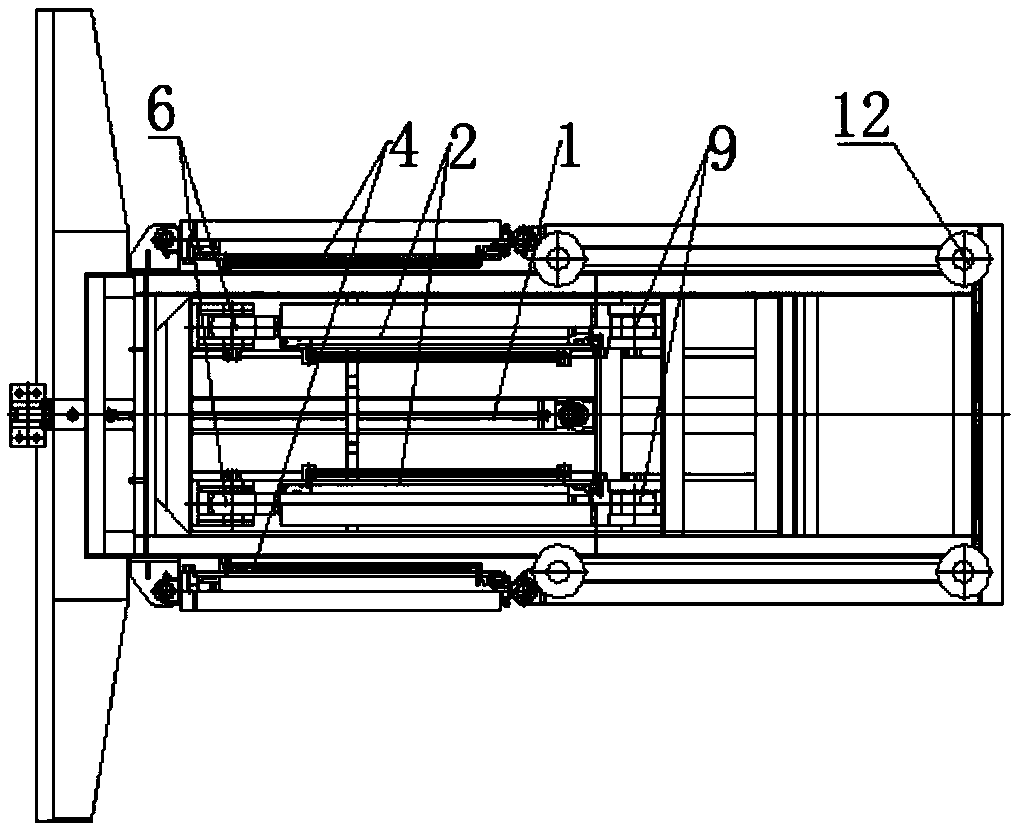

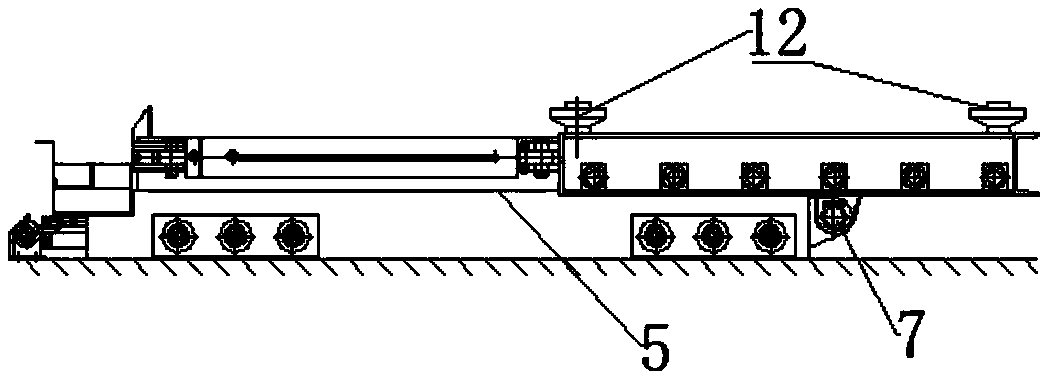

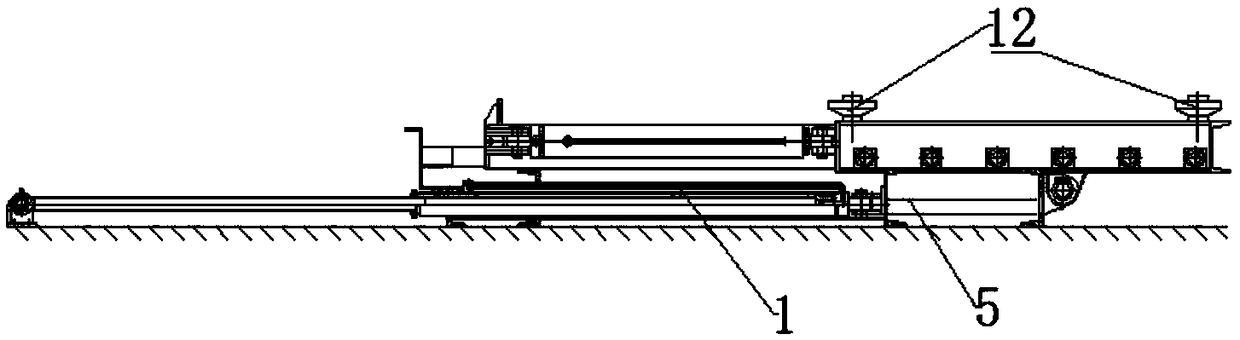

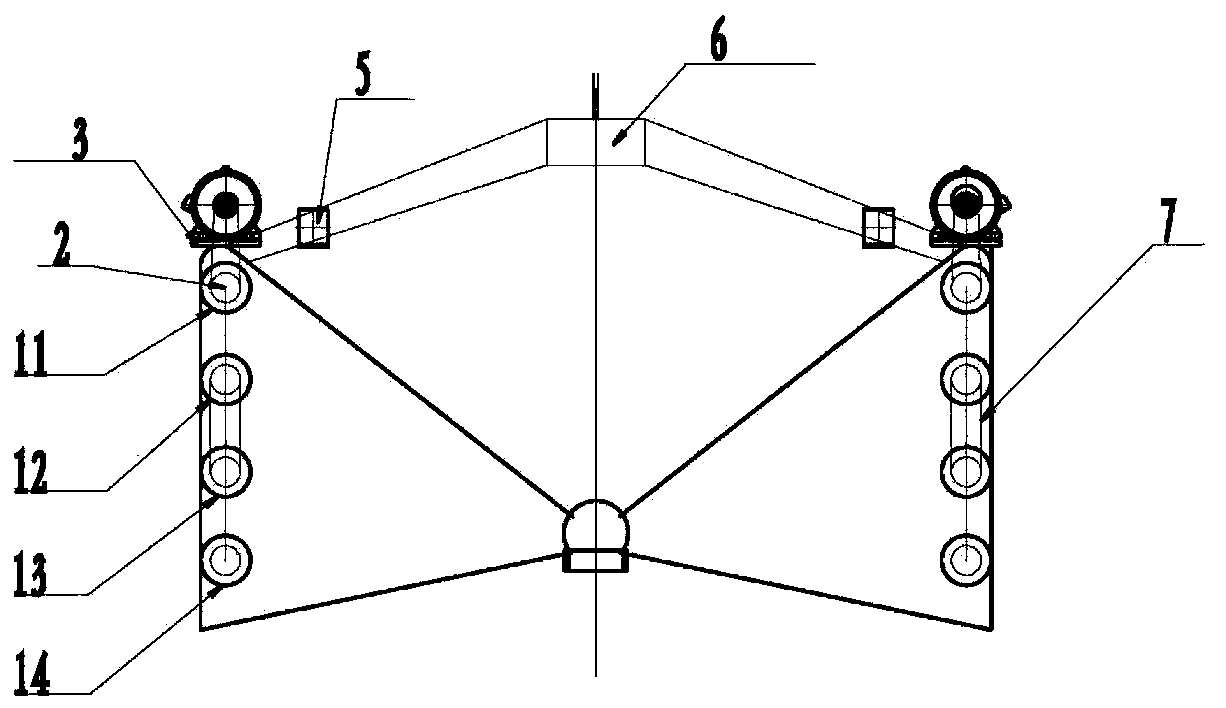

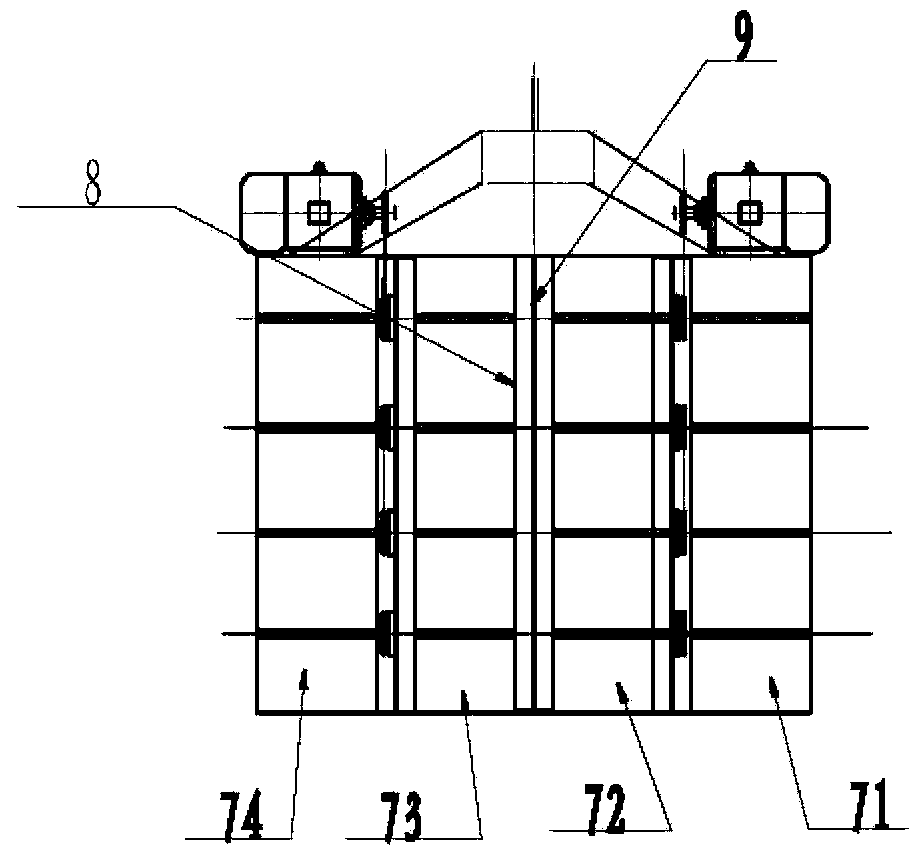

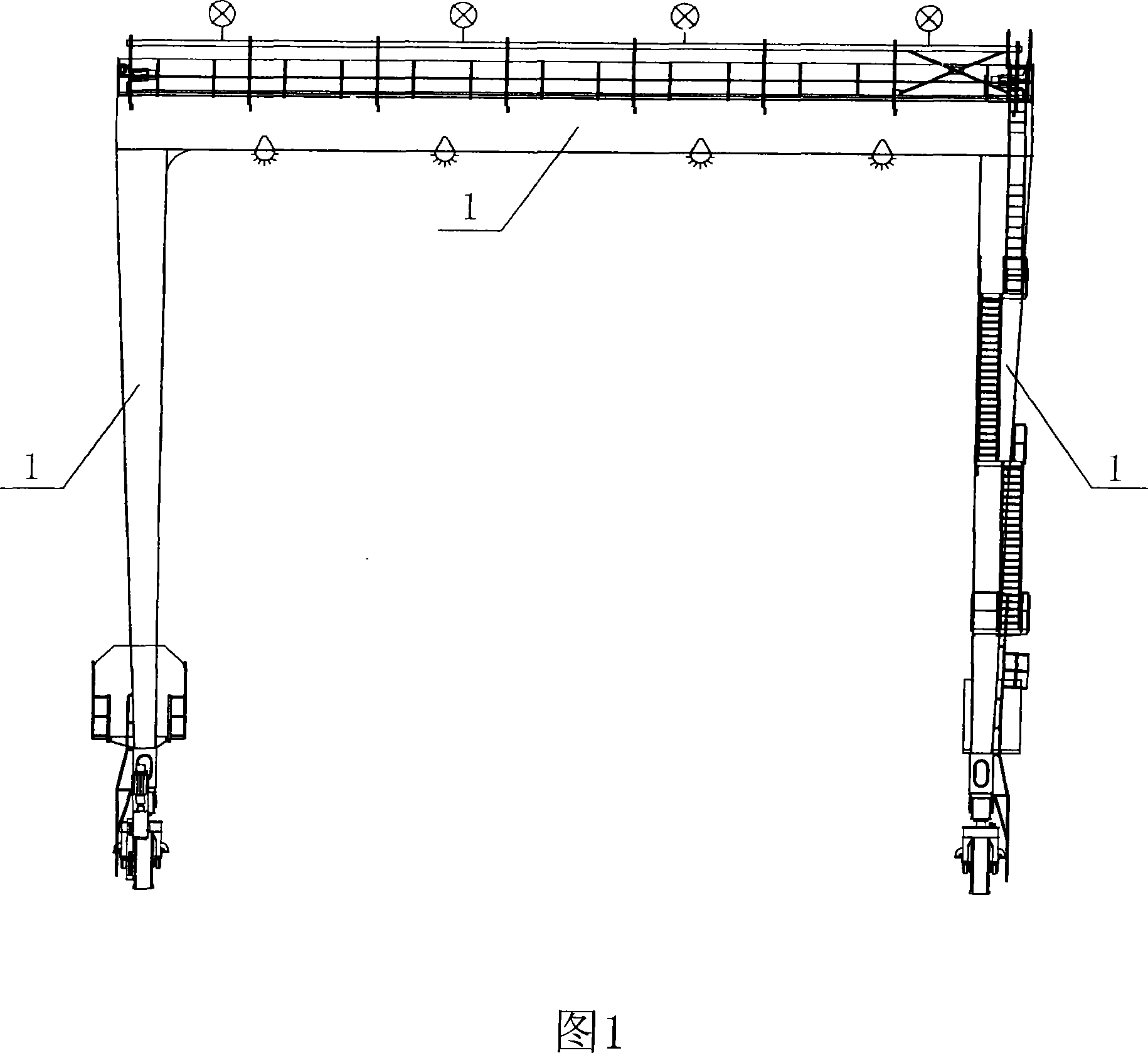

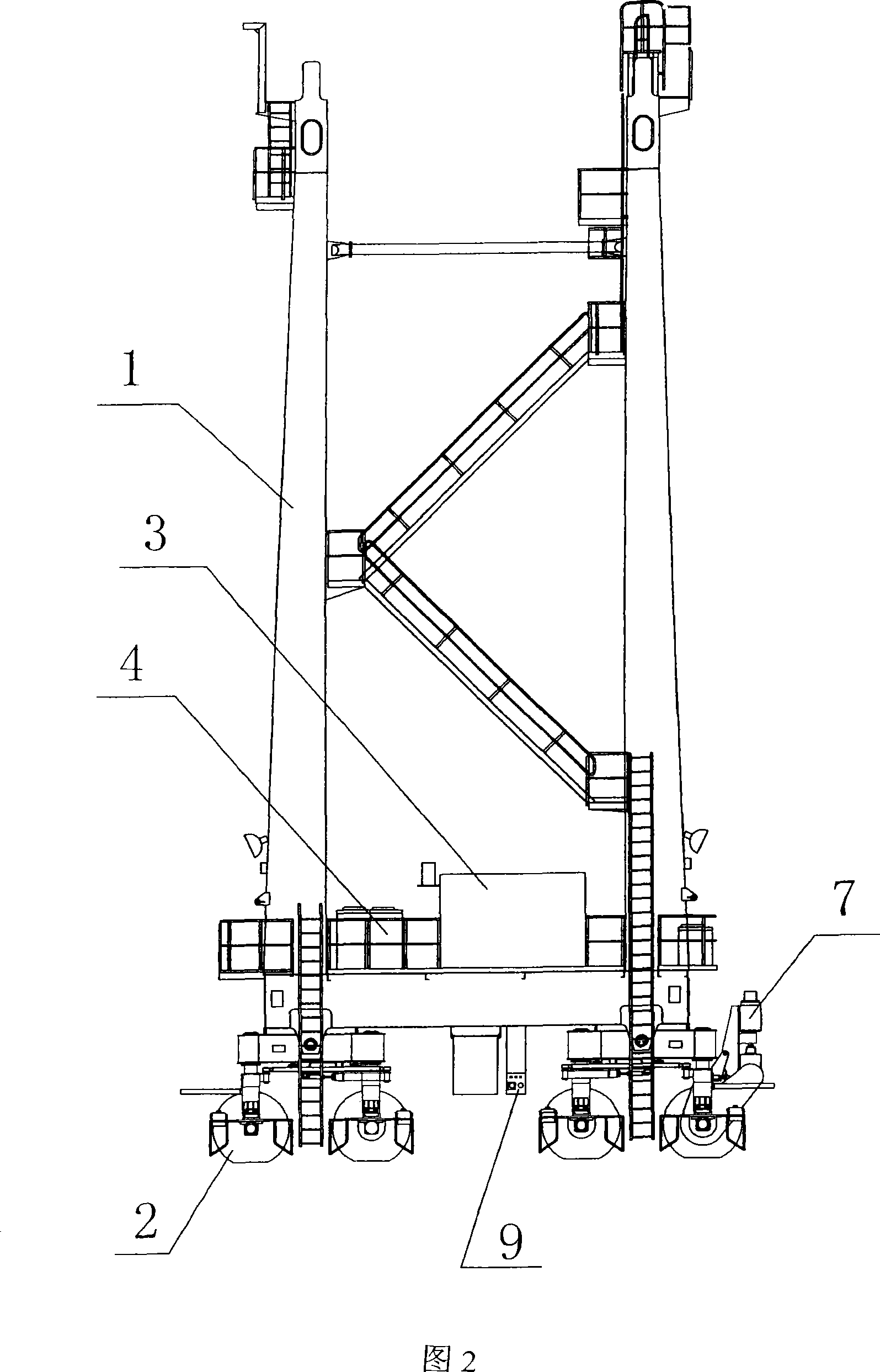

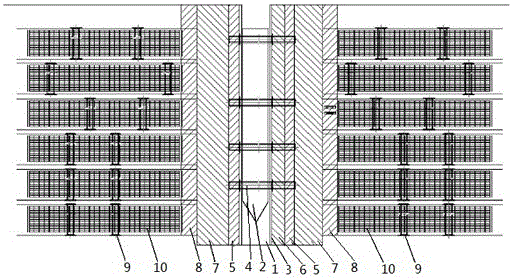

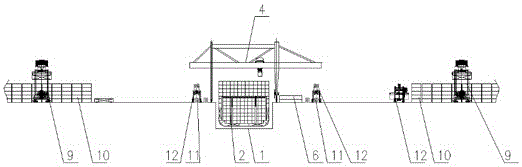

Container crane and method for loading and unloading containers using crane

InactiveCN102139831BReasonable optimization of combined job node settingsReduce waiting time for card collectionTrolley cranesContainer craneEngineering

The invention provides a container crane and a method for loading and unloading containers using the crane. The container crane comprises a crane girder (3), a main trolley (1) which can move along the crane girder (3), a main trolley lifting appliance (2) which moves along with the main trolley (1), a support pillar (4), a transferring and lifting platform (5) for lifting up and down the containers to be loaded and unloaded, and an auxiliary trolley mechanism, wherein, the auxiliary trolley mechanism comprises an auxiliary trolley (6) which is movably arranged along the crane girder (3), andan auxiliary trolley lifting appliance (7) which is arranged on the auxiliary trolley (6) and is used for loading and unloading the containers on the transferring and lifting platform (5). The container crane provided by the invention has the advantages of reasonably optimizing setup of combined operation nodes, maximally reducing the possibility of waiting for a container truck during the loading and unloading process, enhancing cost performance of equipment, and improving operating efficiency. The container crane is used for loading and unloading the containers by utilizing the method.

Owner:SANY MARINE HEAVY IND

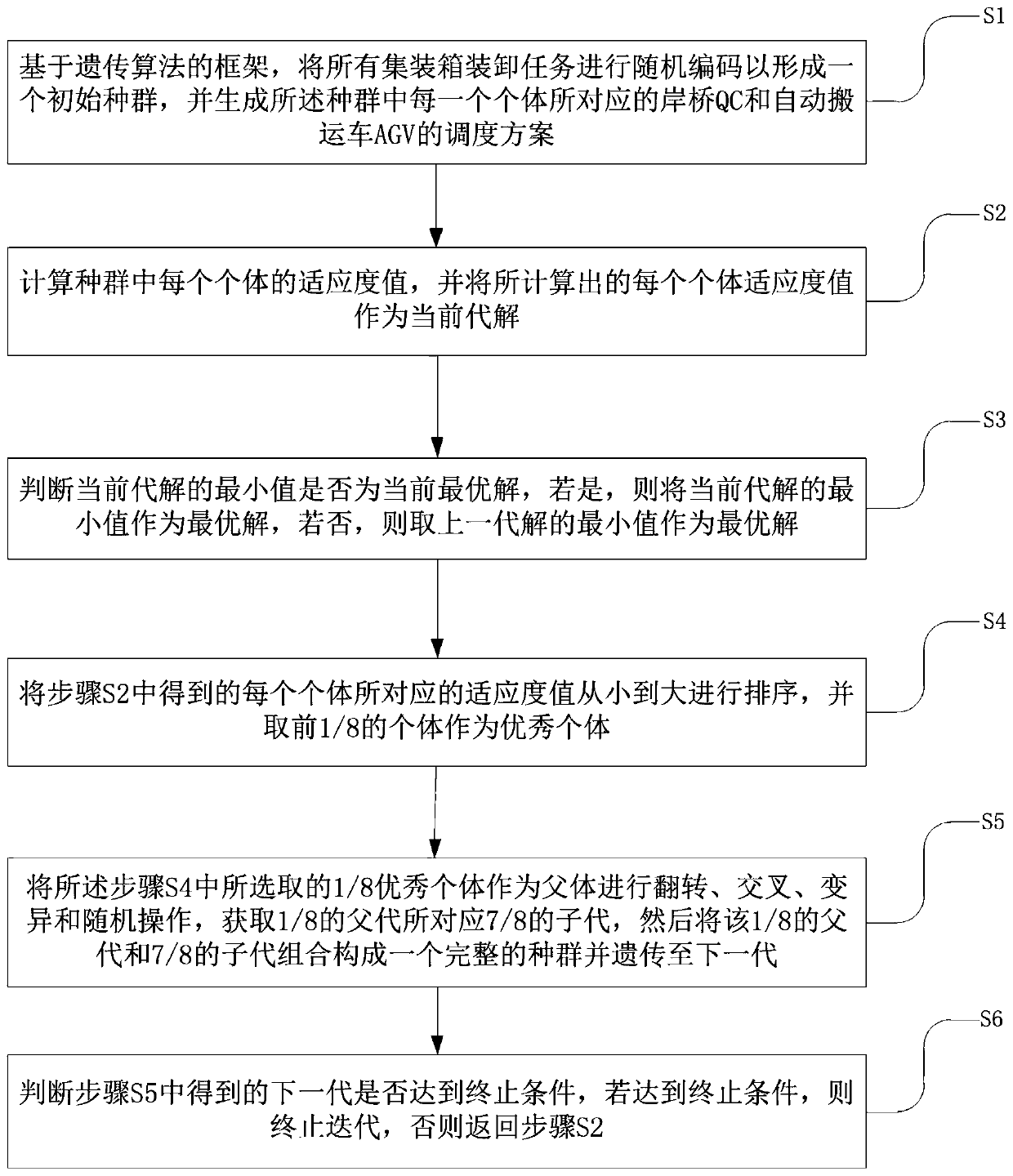

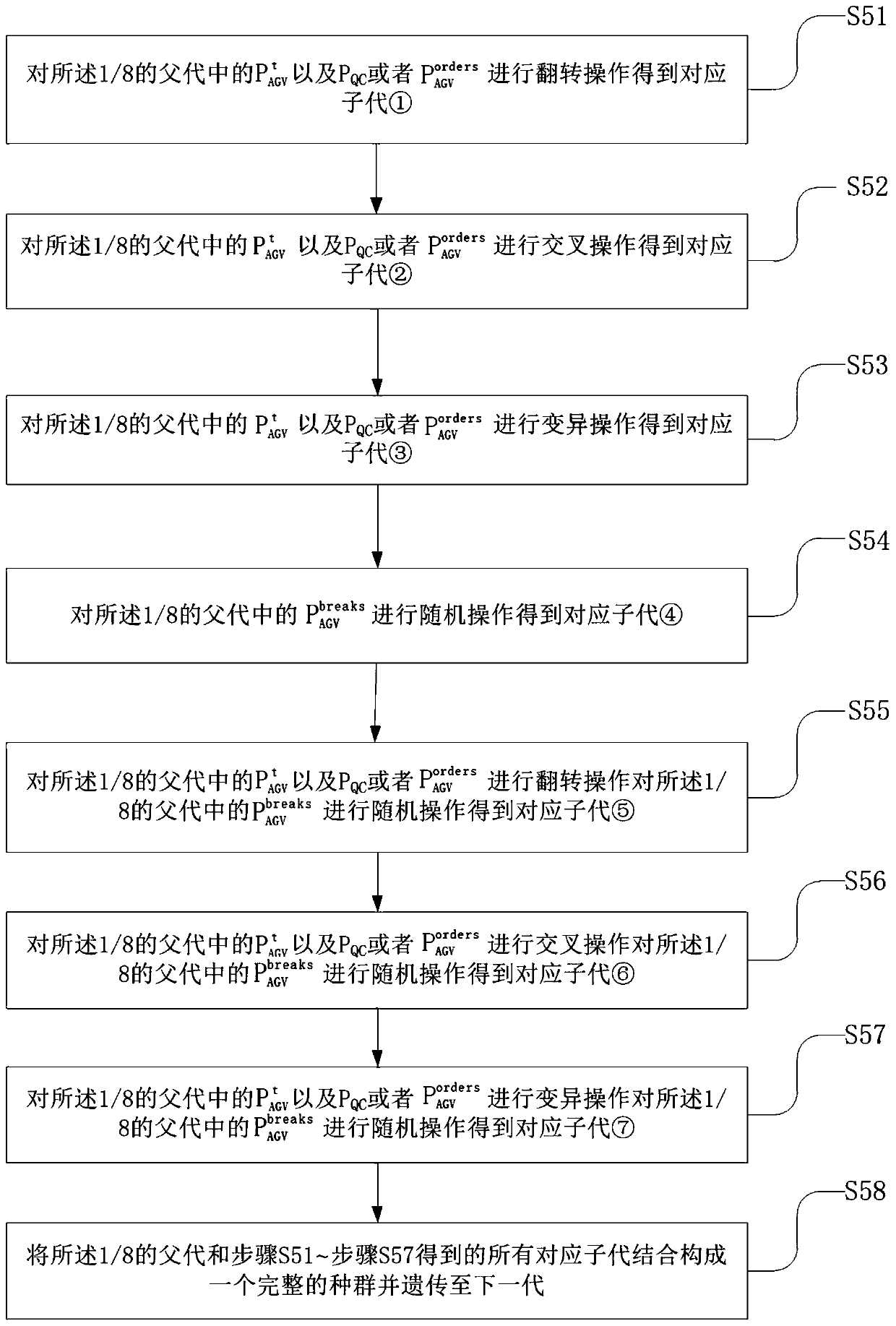

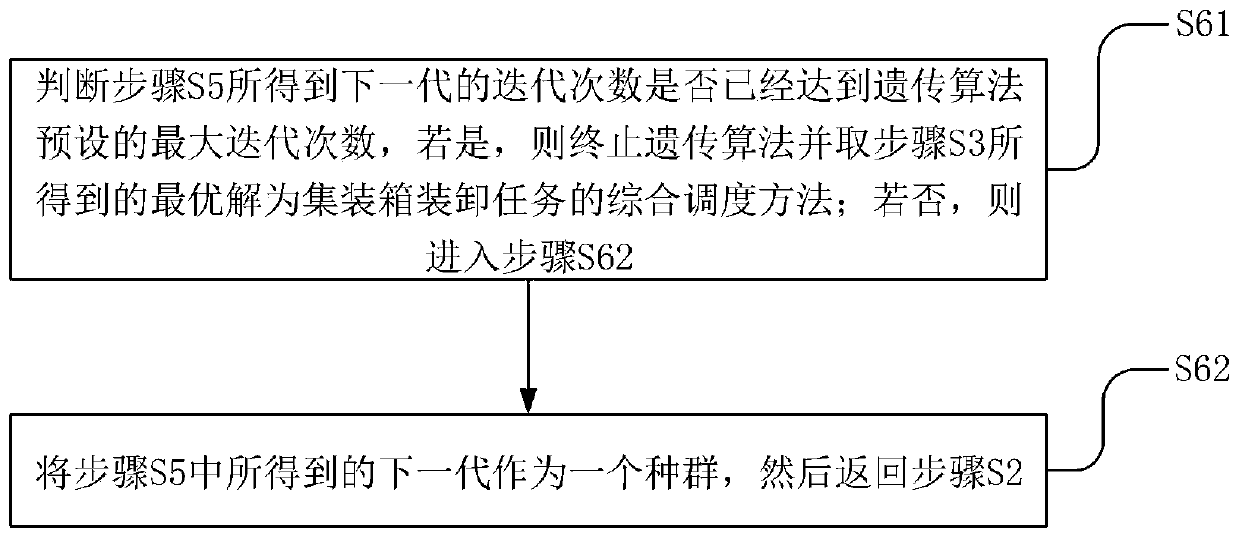

Intelligent energy-saving comprehensive dispatching method for automatic container wharf

ActiveCN111325481AReduce energy consumptionReduce lossResourcesLogisticsSimulationGenetics algorithms

The invention particularly discloses an intelligent automatic container wharf energy-saving comprehensive scheduling method which comprises the following steps: S1, based on a framework of a genetic algorithm, randomly encoding a container loading and unloading task to form an initial population; s2, calculating a fitness value of each individual in the population as a current generation solution;s3, judging whether the minimum value of the current generation solution is the current optimal solution or not; s4, sorting the fitness values of the individuals from small to large, and taking thefirst 1 / 8 individuals as excellent individuals; s5, taking the selected 1 / 8 excellent individuals as male parents to perform overturning, crossing, variation and random operation, obtaining 7 / 8 filialgenerations corresponding to the 1 / 8 male generations, then combining the 1 / 8 male generations and the 7 / 8 filial generations to form a complete population, and inheriting the complete population tothe next generation; and S6, judging whether the next generation obtained in the step S5 reaches a termination condition or not, if so, terminating the algorithm, and otherwise, returning to the stepS2. According to the invention, the container loading and unloading operation efficiency is improved, and the energy consumption of equipment is remarkably reduced.

Owner:ZHENGZHOU UNIV

Hydraulic loading and unloading system

InactiveCN109435813AImprove the efficiency of loading and unloading operationsRealize automatic loading and unloadingLoading/unloadingVehicle with tipping movementCylinder headPetroleum engineering

The invention discloses a hydraulic loading and unloading system. The hydraulic loading and unloading system comprises a horizontal pushing oil cylinder, a horizontal pushing mechanism, a turnover oilcylinder, a turnover mechanism, an up-down oil cylinder and an up-down mechanism, wherein a cylinder head of the horizontal pushing oil cylinder is connected with the horizontal pushing mechanism, and is used for driving the horizontal pushing mechanism to horizontally and linearly move along the floor of a carriage; the turnover mechanism comprises a cargo releasing platform; the back surface ofthe cargo releasing platform is hinged to the horizontal pushing mechanism; the tail end of the turnover oil cylinder is hinged to the horizontal pushing mechanism, and the cylinder head of the turnover oil cylinder is hinged to the back surface of the cargo releasing platform; the turnover oil cylinder is used for driving the cargo releasing platform to overturn at an angle of 0-90 degrees relative to the position where the cargo releasing platform is hinged to the horizontal pushing mechanism; the up-down mechanism is connected with the cargo releasing platform, and is positioned on the horizontal pushing mechanism; and the tail end of the up-down oil cylinder is connected with the cargo releasing platform and the cylinder head of the up-down oil cylinder is connected with the up-down mechanism and is used for driving the up-down mechanism to move linear. The hydraulic loading and unloading system can rapidly load and unload cargoes, the time and labor are saved, and the loading andunloading operation efficiency is improved.

Owner:BEIJING ANLONG TECH GRP

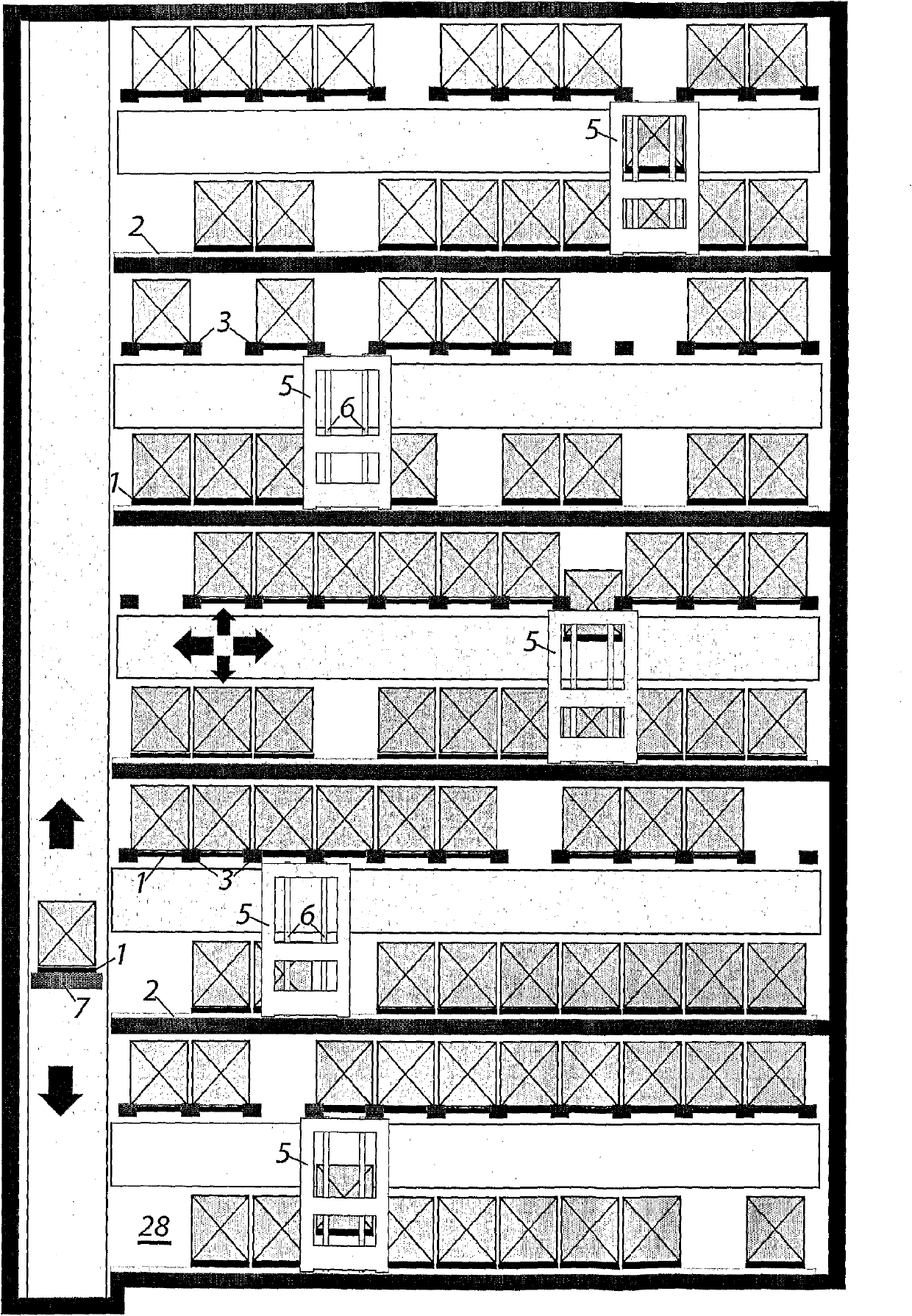

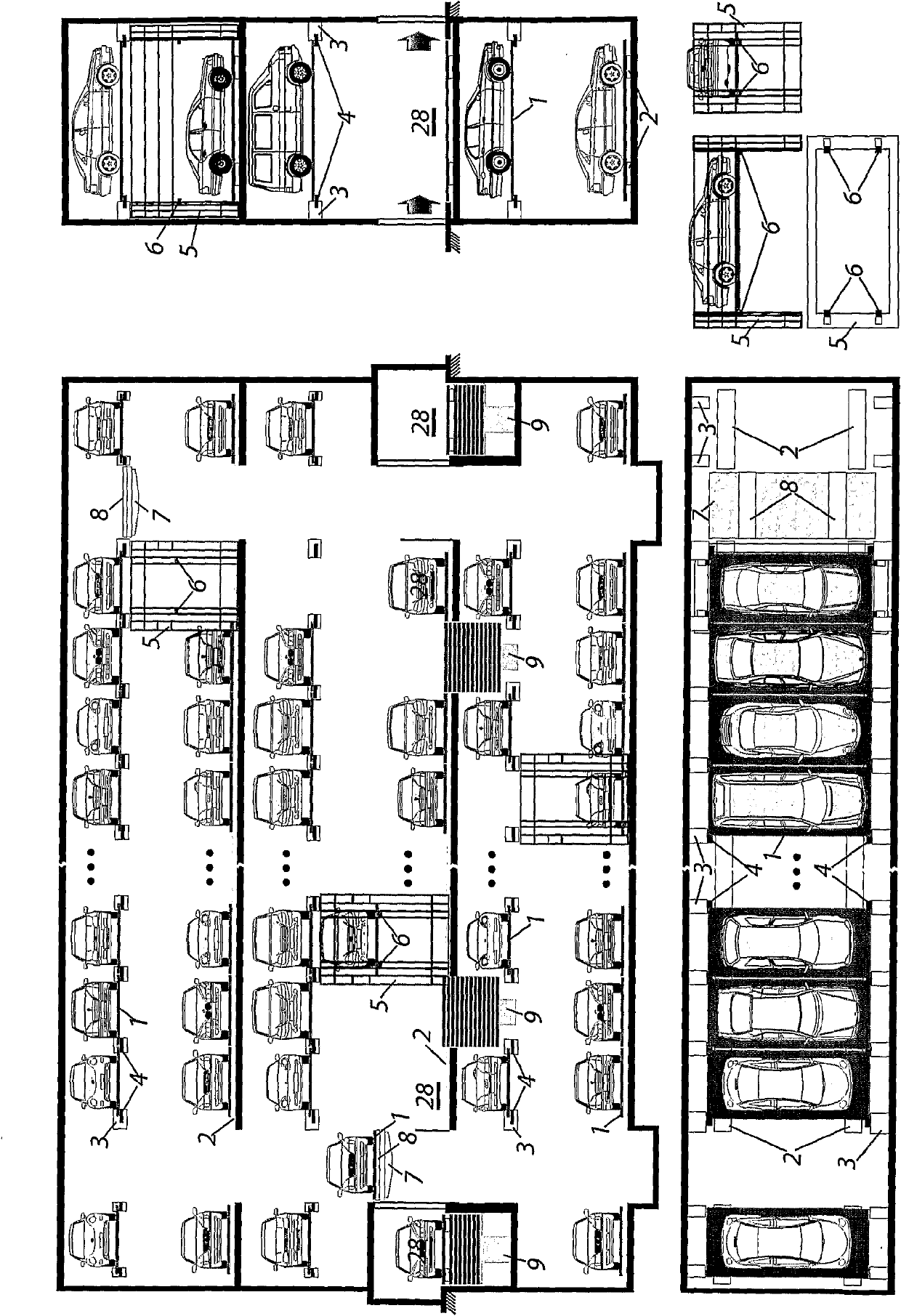

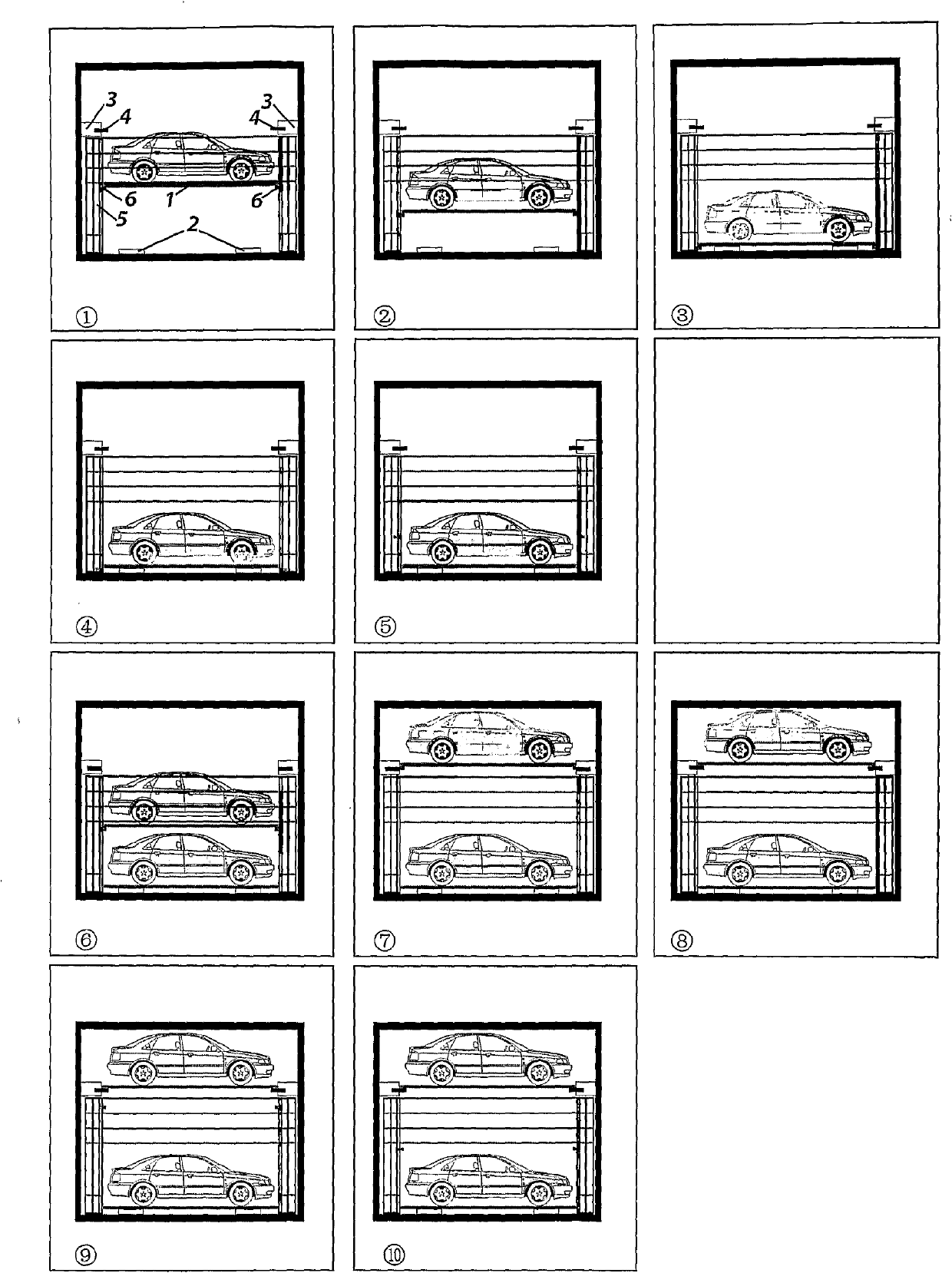

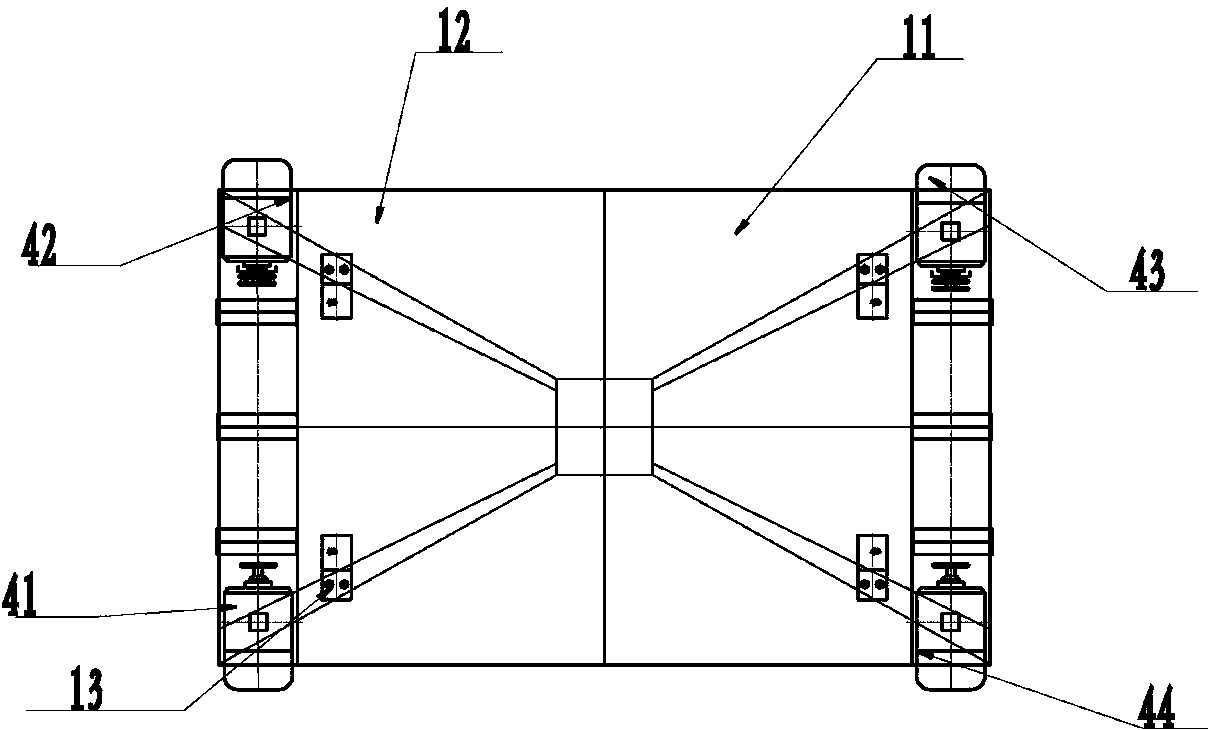

Method and system of stereo warehouse/parking and container stereo warehousing system, container terminal and method for loading and unloading operation of container terminal

InactiveCN101208490BIncrease profitSolve the problem of accessing playbackStorage devicesParkingsVertical channelPallet

Owner:张宁

Double-jaw grab bucket device of crane

InactiveCN110902558AReduce stickingReduce coefficient of frictionLoad-engaging elementsFrictional coefficientClassical mechanics

The invention relates to a double-jaw grab bucket device of a crane and particularly relates to a grab bucket device for loading and unloading mineral powder particles with the high water content. Theinvention provides a solution which is simple in structure and convenient to operate in order to overcome two defects that in the prior art, when a grab bucket of a crane is used for loading and unloading high-water-content mineral powder, material taking is insufficient, and unloading is not clear. For an improved device, on the basis of a grab bucket in the prior art, a controllable driving rolling bar set with a stirring function is additionally arranged between the grab bucket and powder, the binding power of the loaded and unloaded powder and a friction coefficient between the powder andthe grab bucket are reduced, and the improved device is characterized in that the grab bucket device comprises an open-close type grab bucket, a motor, a portable power source, a transmission chain wheel, a chain and the driving rolling bar set. Compared with the prior art, the grab bucket device is simple in structure and convenient to operate, the binding power of the powder and the friction coefficient between the powder and the grab bucket can be effectively reduced, and loading and unloading operation efficiency of the crane is improved.

Owner:TANGSHAN IND VOCATIONAL TECHN COLLEGE

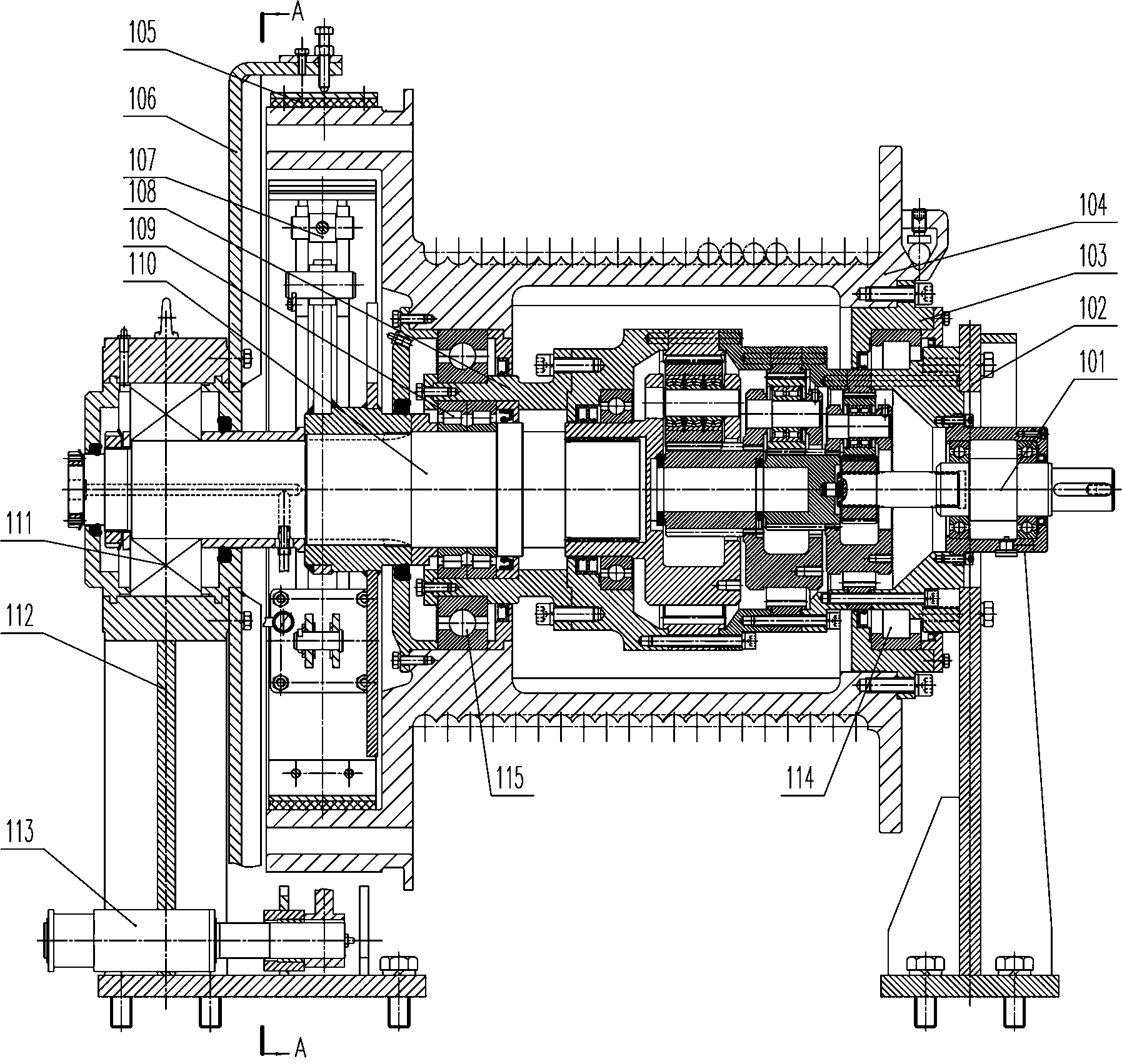

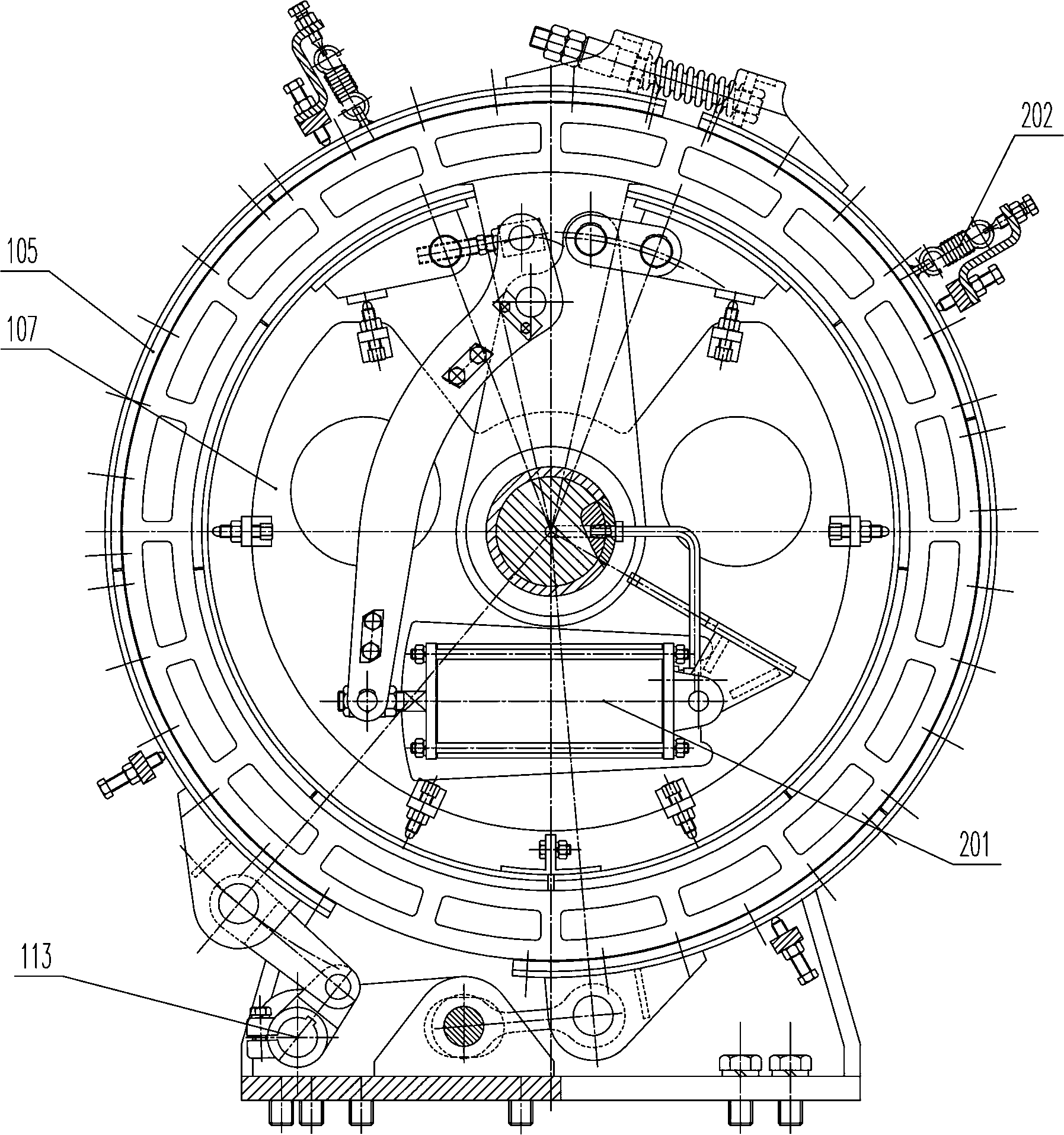

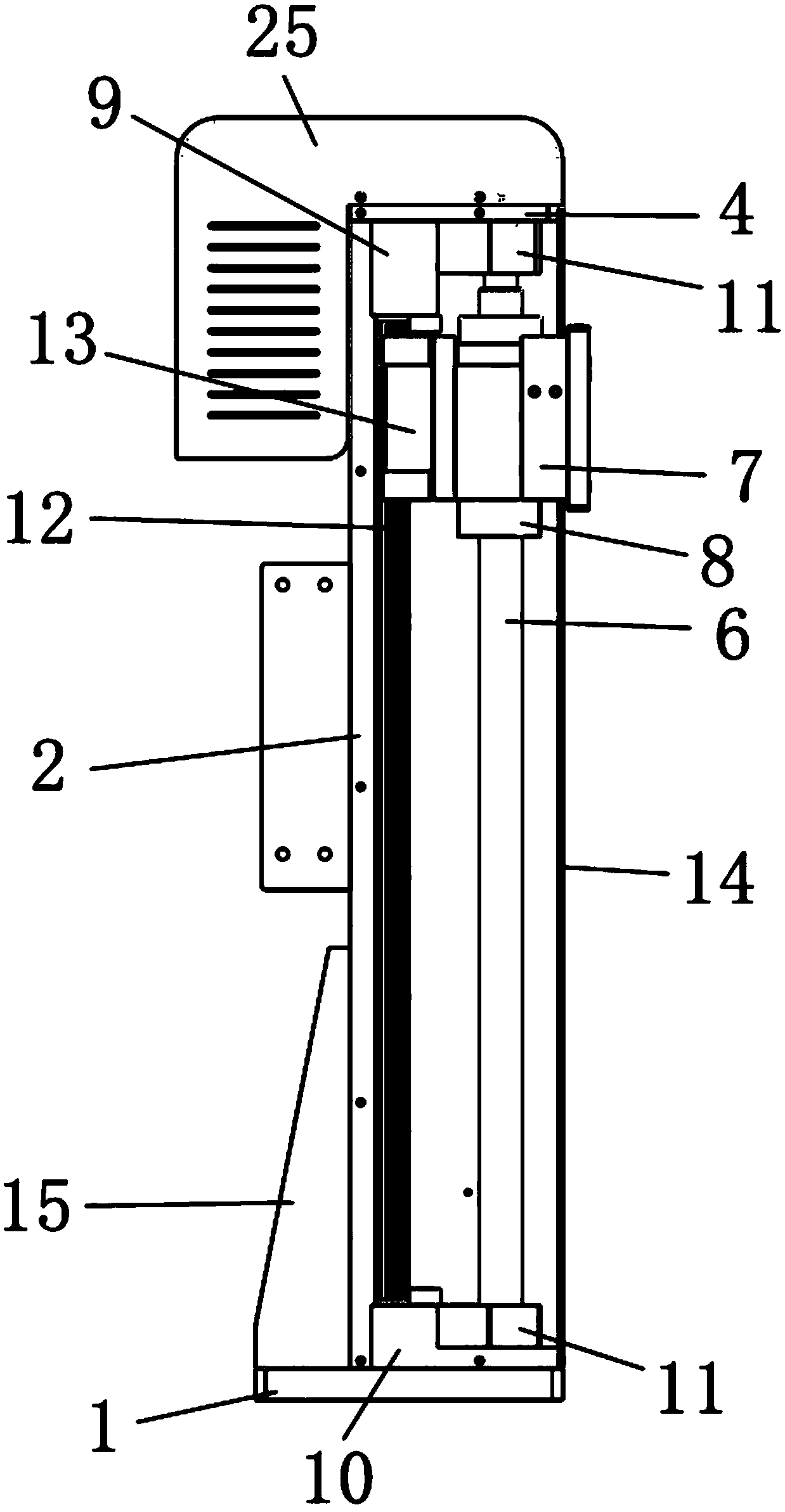

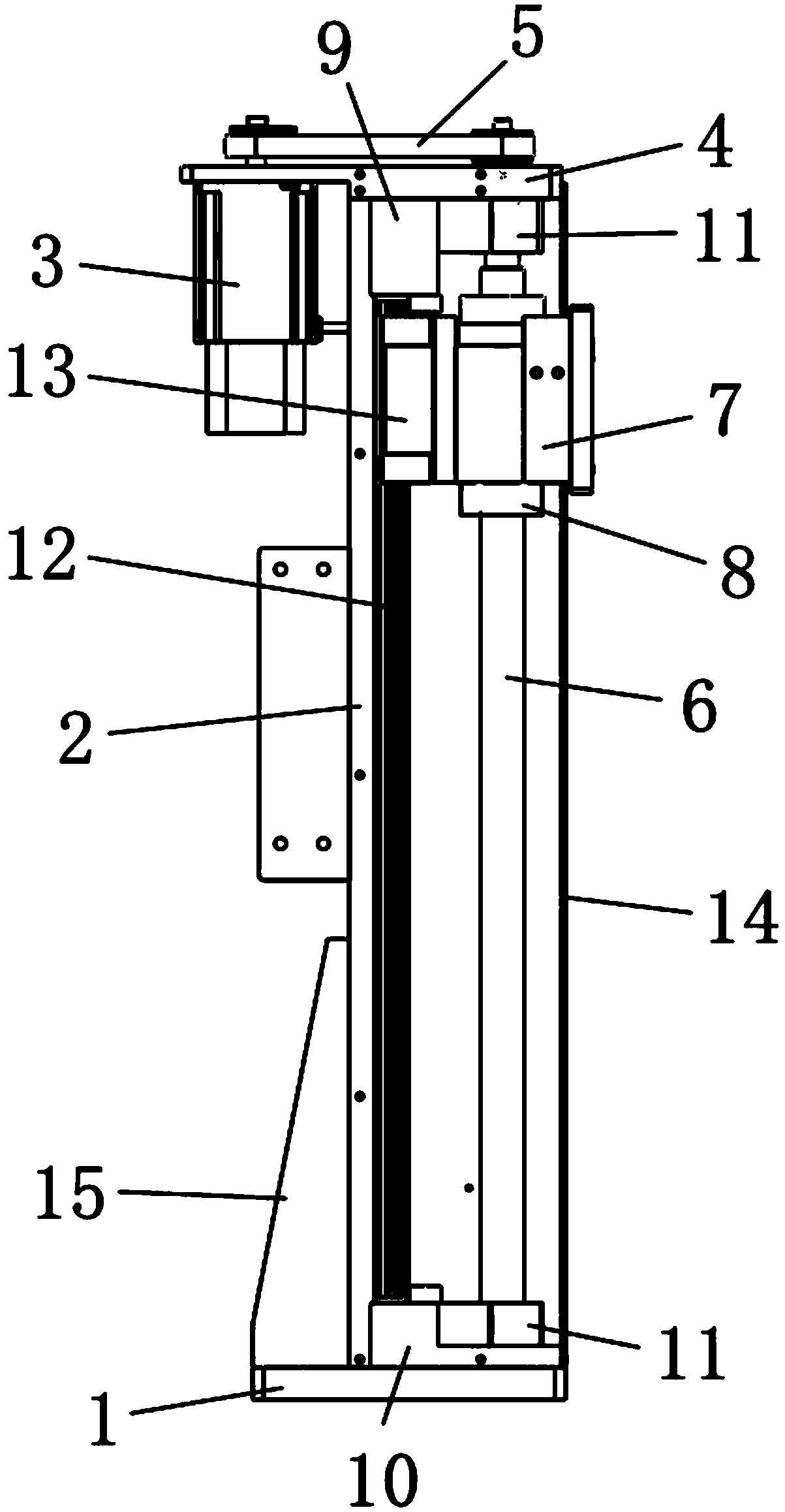

Speed-controllable gravity lowing winch provided with built-in gear reducer

InactiveCN103303830AImprove the efficiency of loading and unloading operationsAchieve gravity descentWinding mechanismsReduction driveDrive shaft

The invention relates to a speed-controllable gravity lowing winch provided with a built-in gear reducer. The built-in gear reducer is arranged in a winding drum; a casing at an input end of the built-in gear reducer is fixed on a winch support; a transmission shaft is fixedly connected with an output end of the built-in gear reducer; the transmission shaft and an input shaft of the built-in gear reducer are coaxially arranged; the built-in gear reducer is provided with a front end casing and a gear reducer lower box; a full floating type internal expanding clutch is mounted on the transmission shaft; a bearing seat supports the transmission shaft through a first bearing; a brake drum outer ring is arranged outside the winding drum and provided with an external expanding belt brake which is hung on the brake drum outer ring in a sleeving manner. The speed-controllable gravity lowing winch is compact in structure, small in size and safe and reliable to use, can not only improve the loading and unloading operation efficiency of hoisting machinery, but also can save energy, and can simultaneously integrate the built-in gear reducer and the full floating type internal expanding clutch in the winding drum, so that a heavy object can be driven to go up and down by a steel wire rope.

Owner:宜昌力道起重机械有限公司

Container gantry crane with bidirectional power supply

InactiveCN100560469CImprove the efficiency of loading and unloading operationsSmooth connectionTrolley cranesEmergency power supply arrangementsDrive wheelEngineering

The invention discloses a container gantry crane with two-way power supply, which comprises a main frame body and drive wheels installed on the left and right sides of the main frame body. In order to realize the two-way power supply of the crane, one The AC power socket is connected to the power circuit inside the crane. In the container gantry crane of the present invention, an AC power socket is respectively installed on the left and right sides of the main frame body to form a two-way independent power supply mode, so that when the crane enters the storage yard, it is not necessary to consider which side of the storage yard the power supply is set on. All can realize the smooth connection of the plug, thereby overcoming the defects of difficult steering and long transition time of the crane, and significantly improving the efficiency of container loading and unloading operations.

Owner:QINGDAO PORT GRP

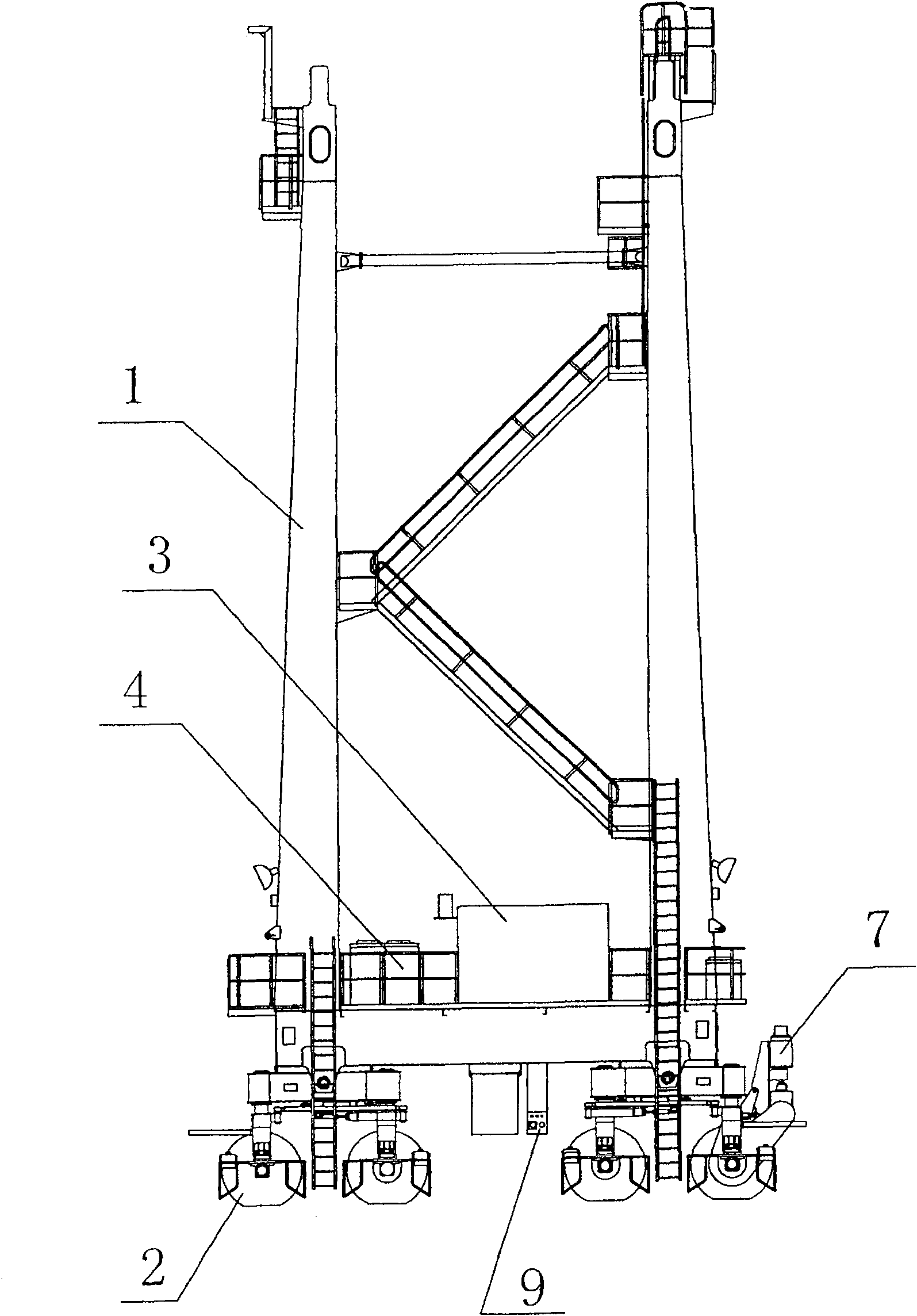

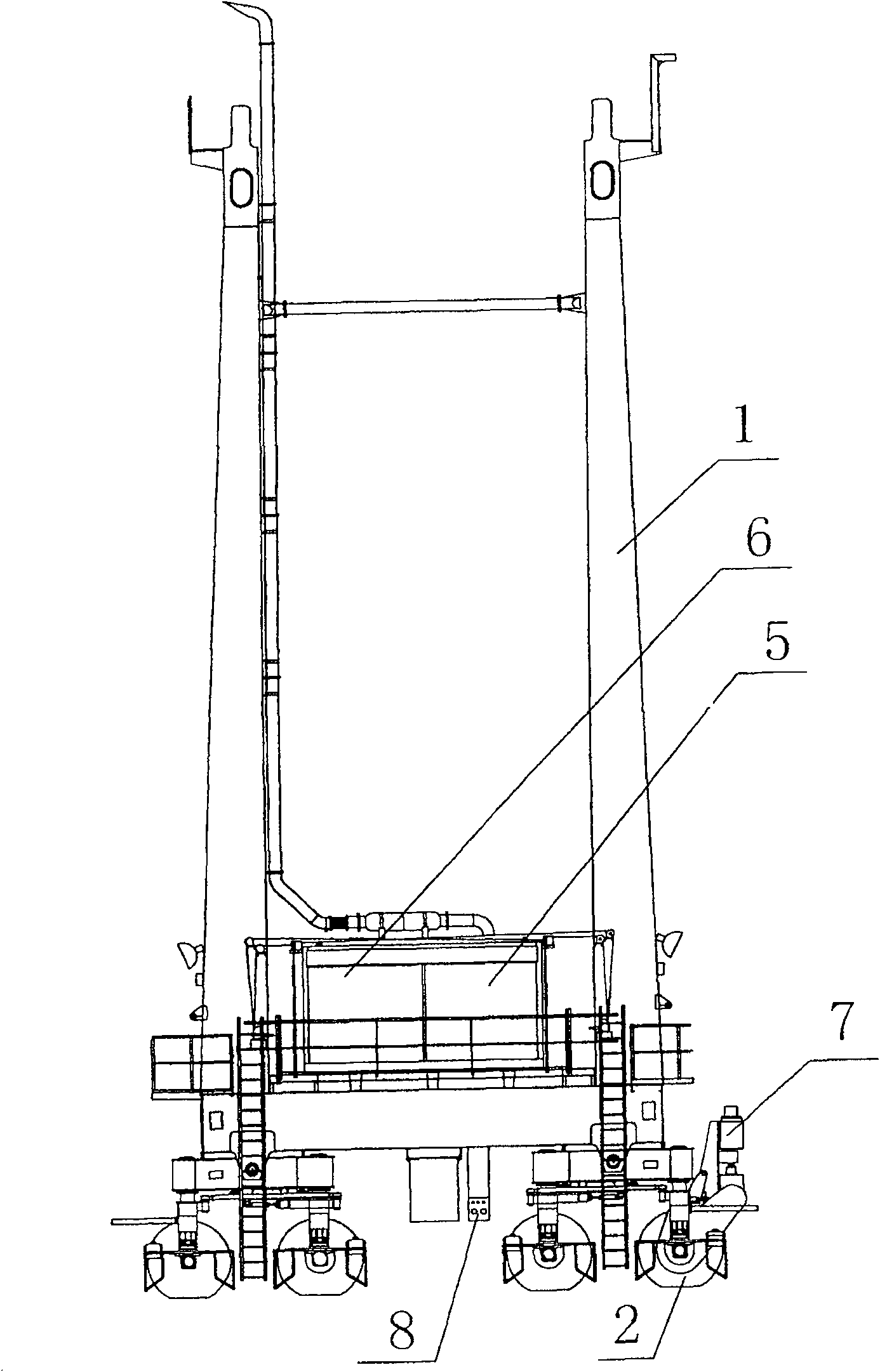

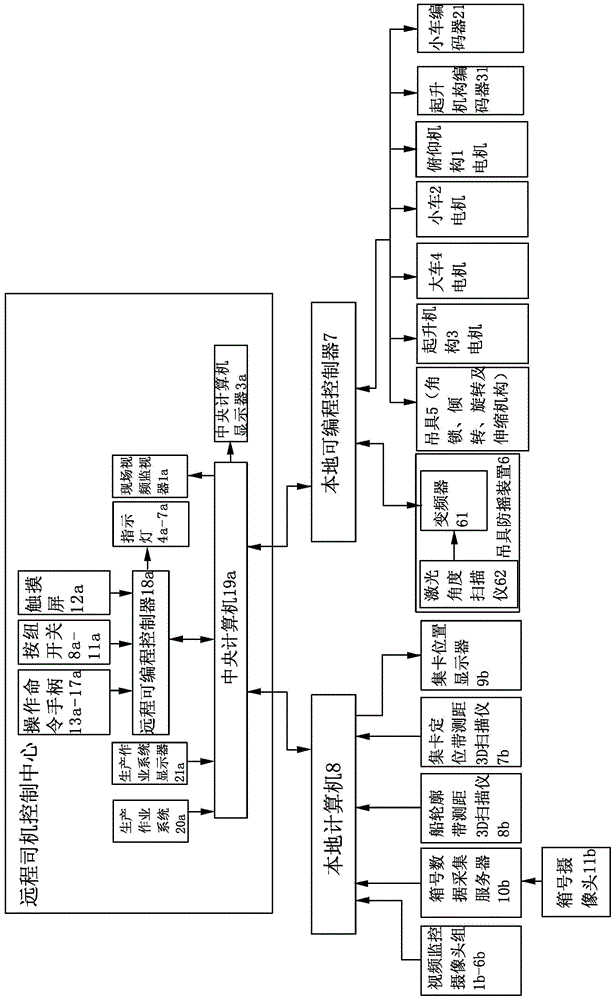

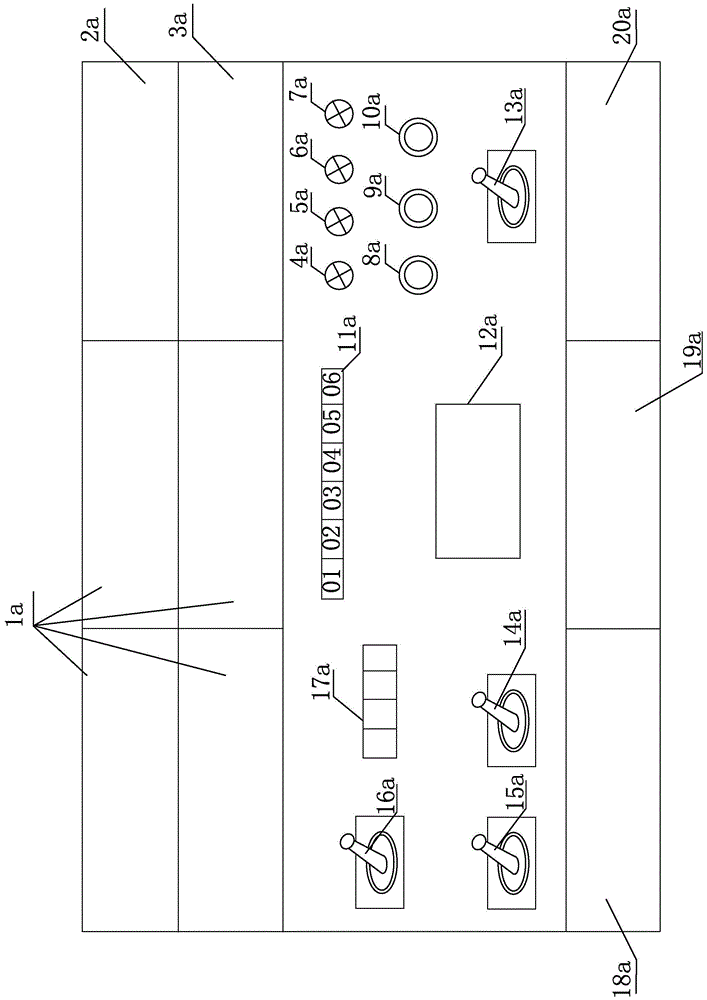

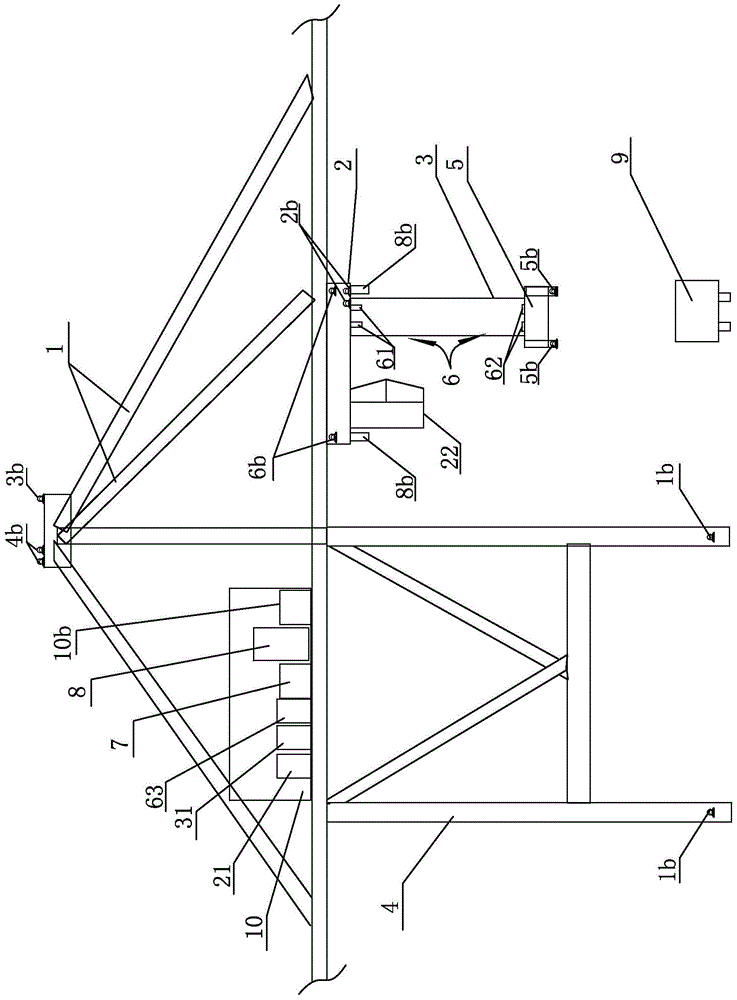

Remote control operating system for loading and unloading operation of quay crane and its operation method

ActiveCN104649146BImprove working comfortReduce labor intensityTravelling cranesLoad-engaging elementsVideo monitoringDisplay device

The invention relates to a quay crane loading and unloading operation remote-control operation system and operation method thereof. The operation system is characterized in that a remote driver controlling center is provided. The remote driver controlling center is provided internally with a central computer, a remote programmable controller, a central computer displayer, an operation command handle, a button switch and an on-site video monitor. The central computer is connected to the central computer displayer, a production and operation system, a production and operation displayer and the on-site video monitor and is also remotely connected to the local programmable controller and a local computer. The local computer is connected to a video monitoring camera, a container number data collector, a ship outline distance measuring 3D scanning instrument, a container truck positioning distance measuring 3D scanning instrument, and a container truck position displayer. The operation method includes following steps: (1) receiving a production operation system command, moving a cart to a bay position, flattening a pitching mechanism and scanning the outline of a ship by a trolley, (2) shipment: regulating the position of the trolley by a container truck driver, determining the container number, aligning and leveling a hoisting device, and performing shipment according to a best loading path; and (3) ship unloading: performing anti-shaking adjustment of the hoisting device, aligning and leveling the hoisting device and unloading the ship according to a best unloading path.

Owner:天津港太平洋国际集装箱码头有限公司

Container gantry crane with bidirectional power supply

InactiveCN101186265AImprove the efficiency of loading and unloading operationsOvercoming steering difficultiesTrolley cranesEmergency power supply arrangementsEngineeringAC power

The invention discloses a container gantry crane with bidirectional power supply, comprising a main frame and driving wheels arranged at the left side and the right side of the main frame. In order to implement the bidirectional power supply of the crane, the left side and the right side of the main frame are respectively provided with an AC power supply socket which is connected with a power supply circuit in the interior of the crane. The container gantry crane of the invention is respectively provided with an AC power supply socket at the left side and the right side of the main frame in order to form bidirectional independent power supply type, thus implementing the smooth connection of the socket when the crane enters the pile field without considering which side of the pile field the power supply is arranged at, further overcoming the defects of the crane of difficult steering and long steering time and obviously improving the efficiency of the loading and unloading operation of the container.

Owner:QINGDAO PORT GRP

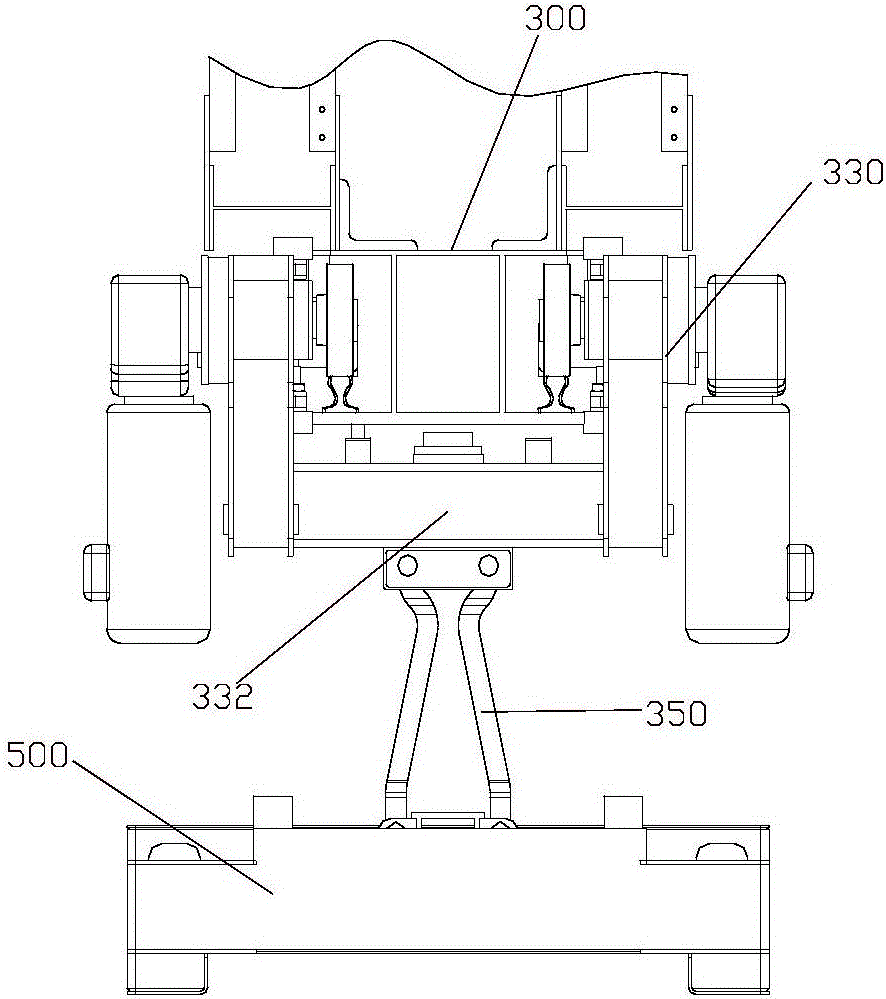

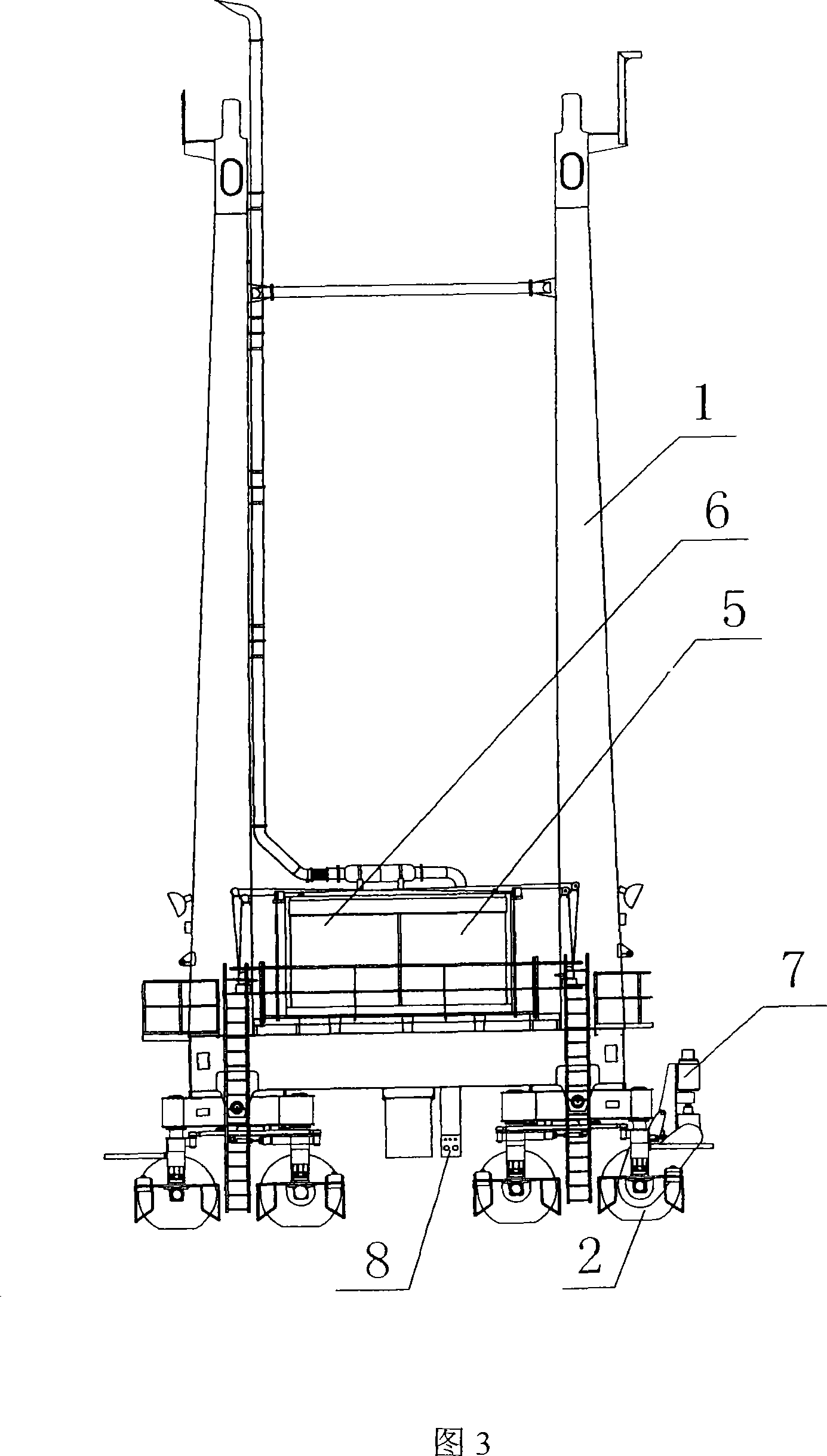

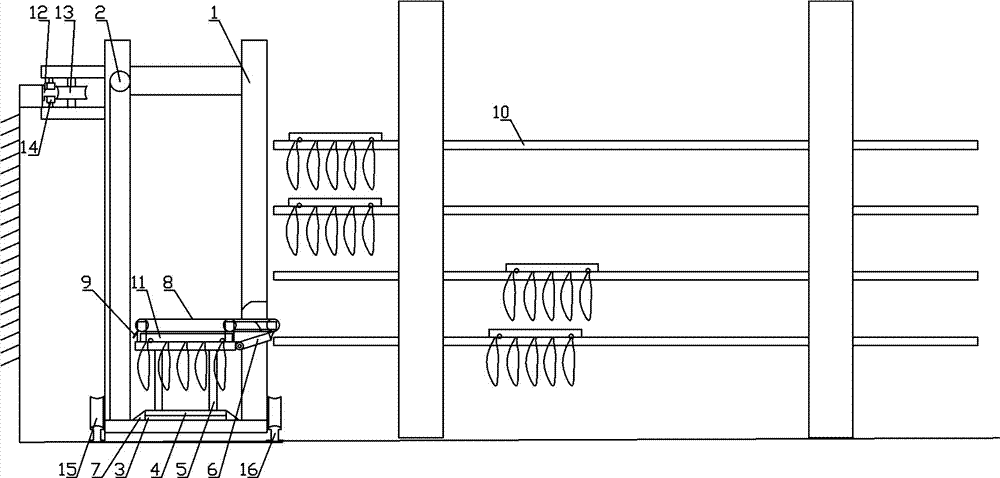

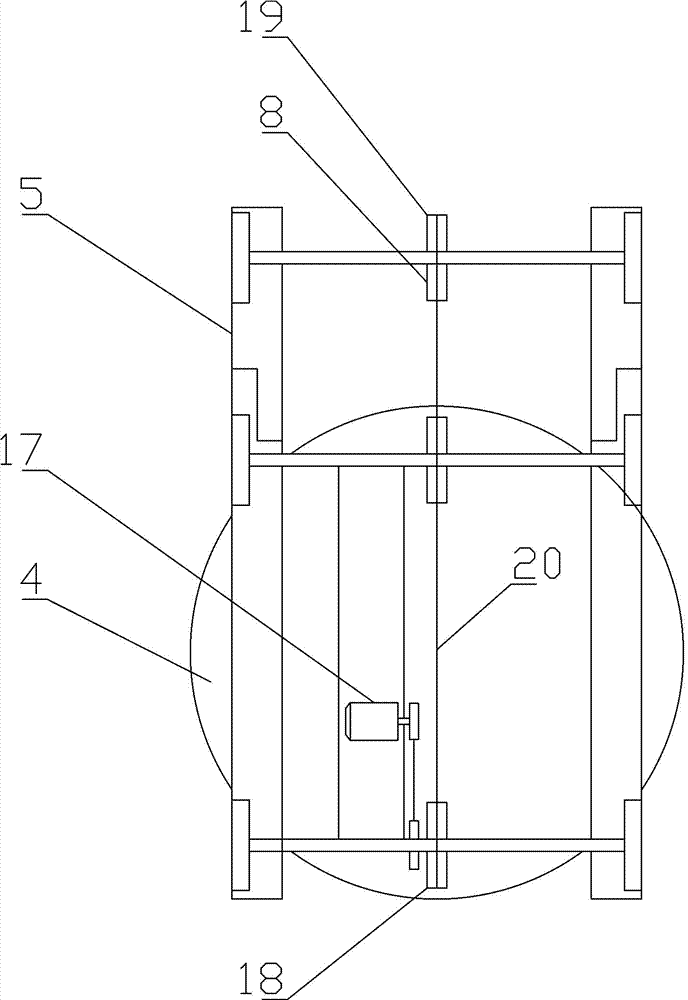

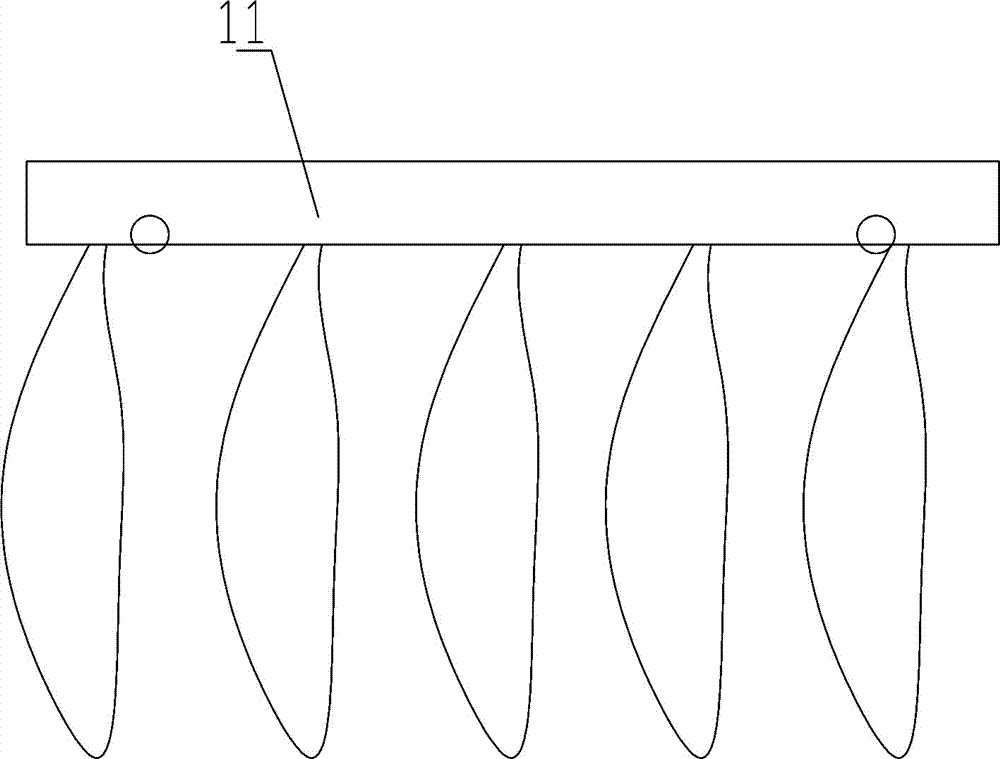

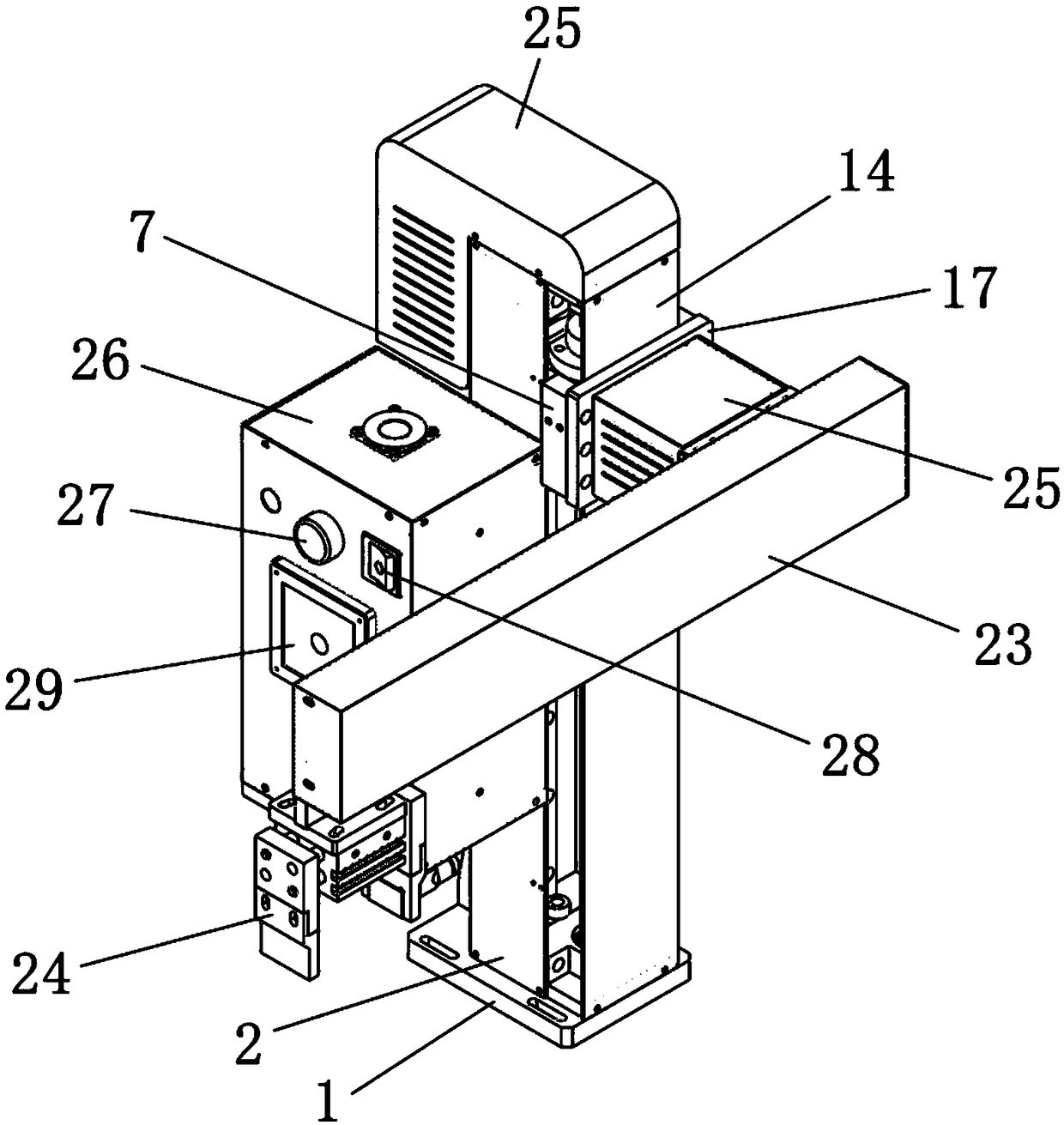

Assembling and disassembling device for sun-cured tobacco sun-curing unit

PendingCN106852511AImprove docking accuracyImprove efficiencyTobacco preparationLap jointEngineering

The invention provides an assembling and disassembling device for a sun-cured tobacco sun-curing unit. A liftable sliding base is installed inside a portal frame. The sliding base is connected with a winding device. A rotating base is installed on the sliding base. A support is fixedly arranged on the rotating base. A lap-joint guide rail is arranged at the end, close to a tobacco sun-curing frame, of the support. A striking device is arranged above the support. By adopting the structures of the portal frame, the winding device, the sliding base and the lap-joint guide rail, and the lap-joint precision between layers of the tobacco sun-curing frame is improved. By adopting the structures of the rotating base and the striking device, an operator can convey the tobacco sun-shading unit to the support from a trolley and conveys to the guide rail of the tobacco sun-curing frame from the support after lifting and positioning, and the assembling and disassembling efficiency is improved.

Owner:宜昌益烟机械设备有限公司

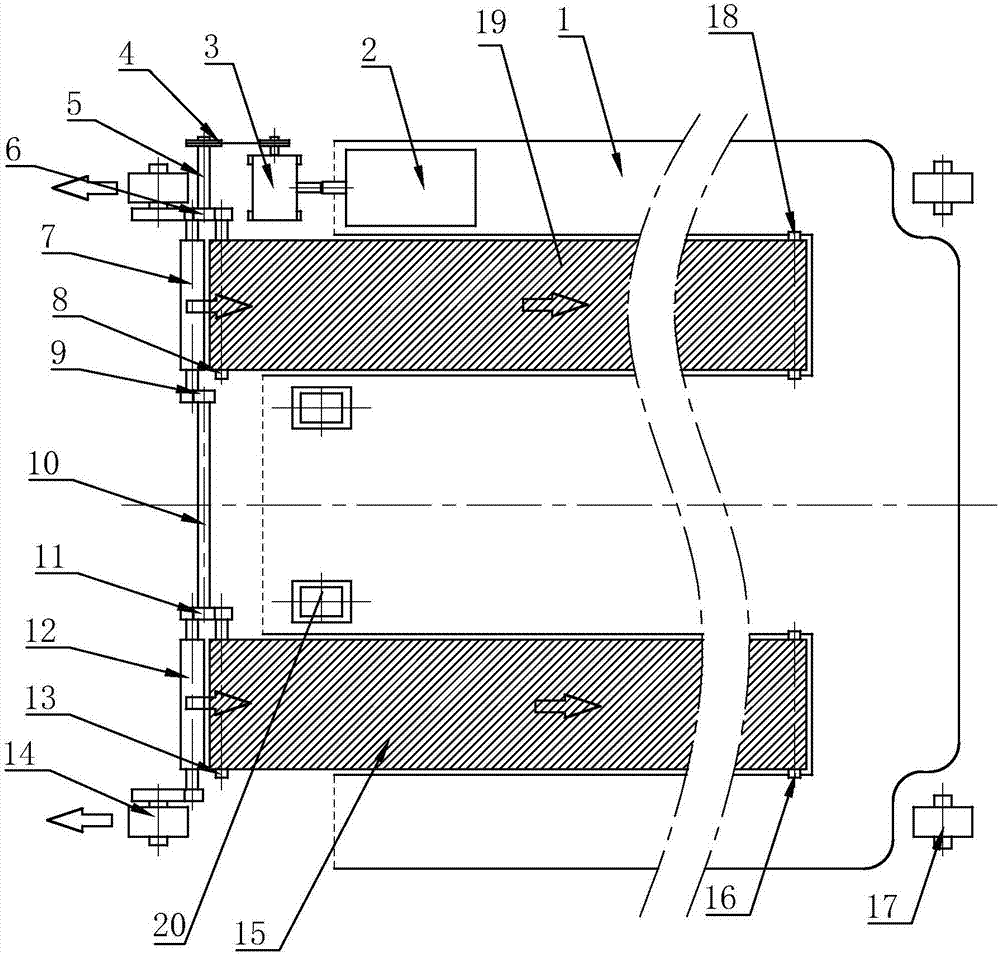

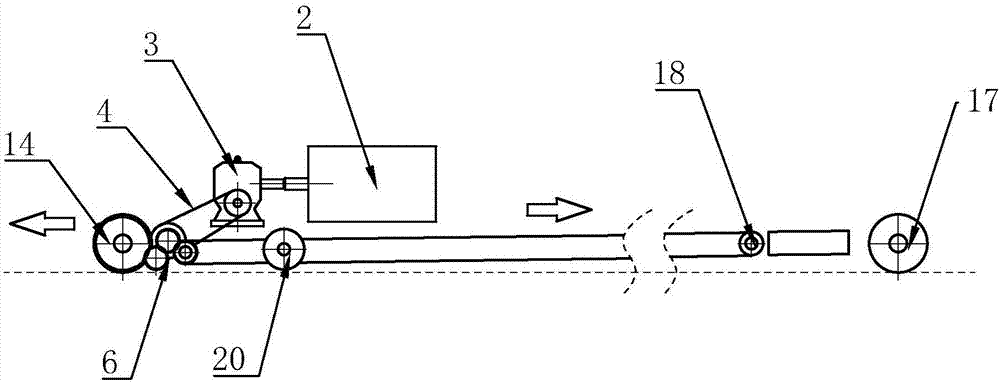

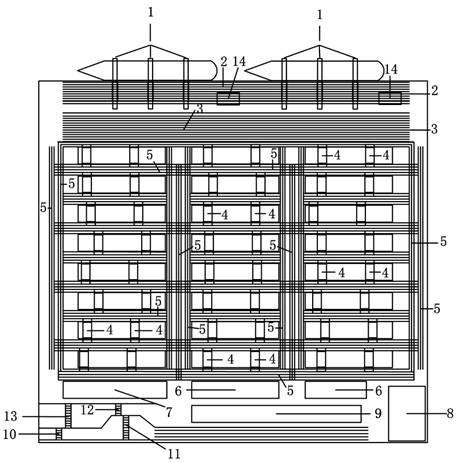

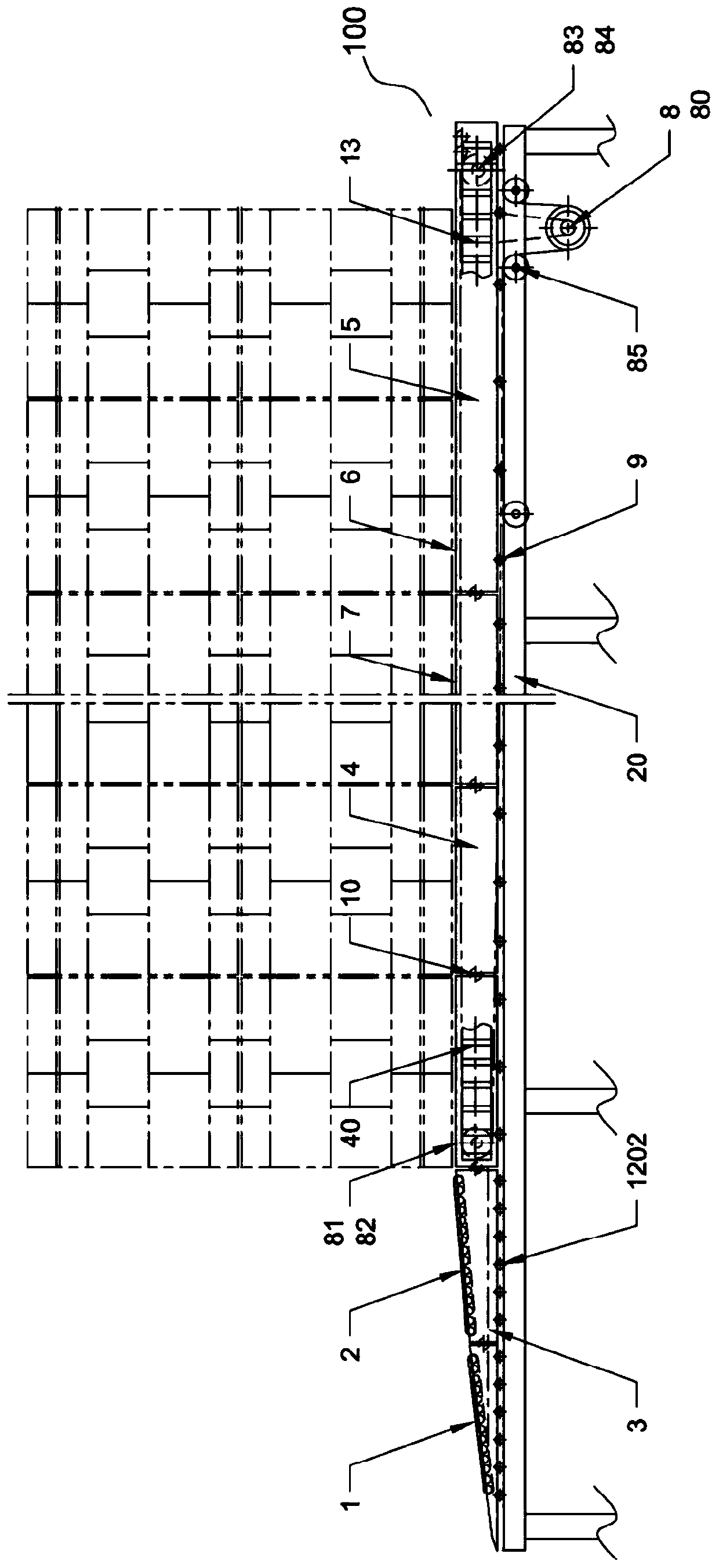

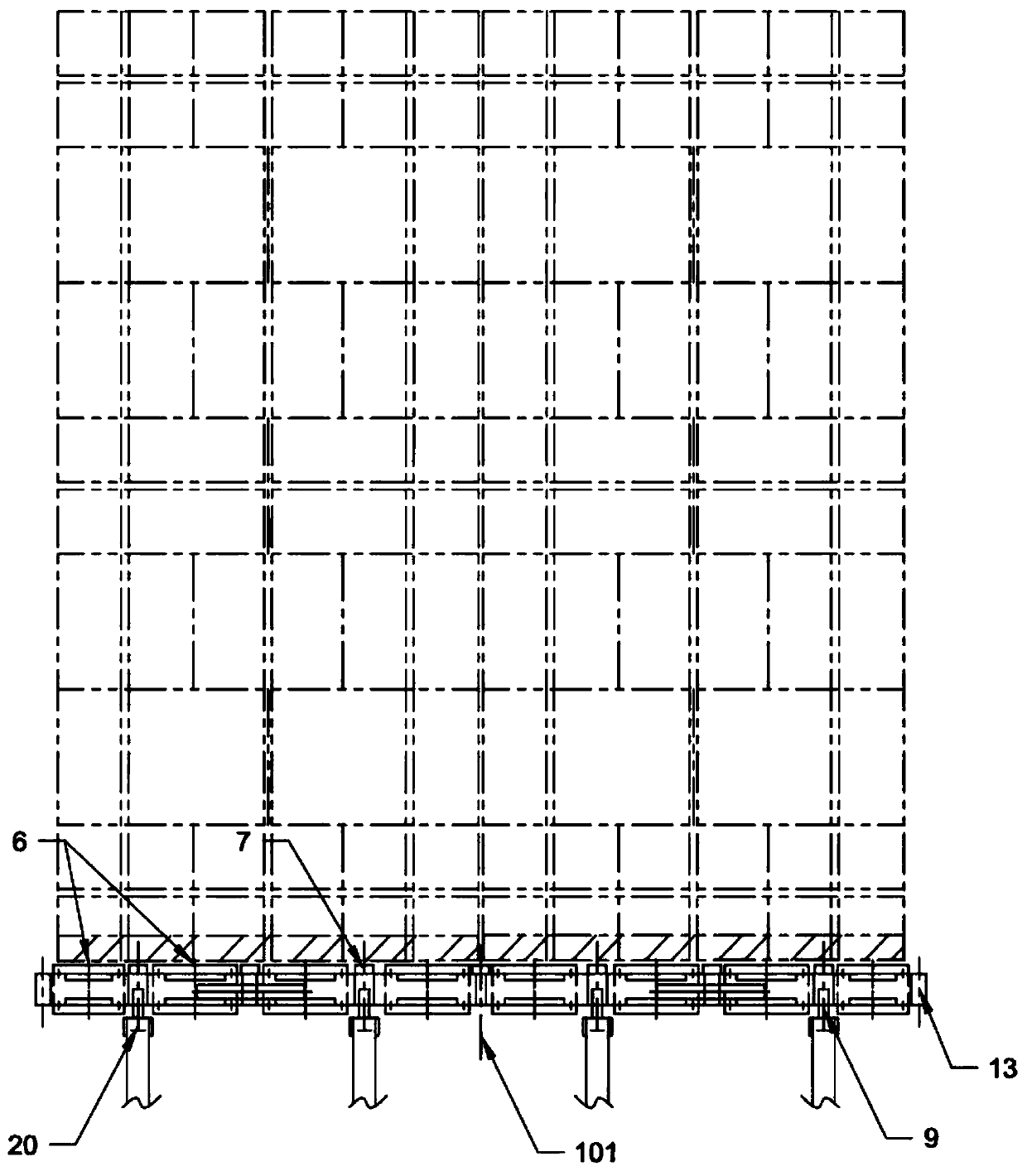

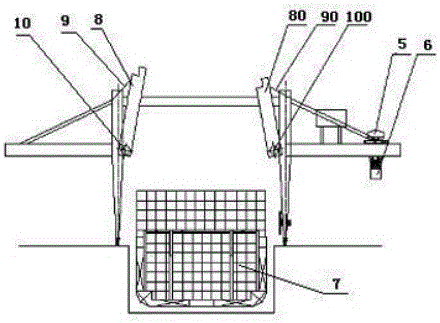

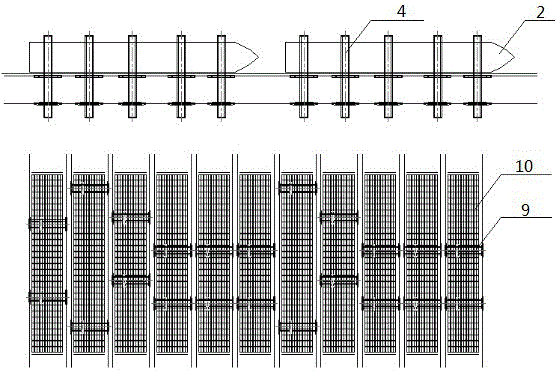

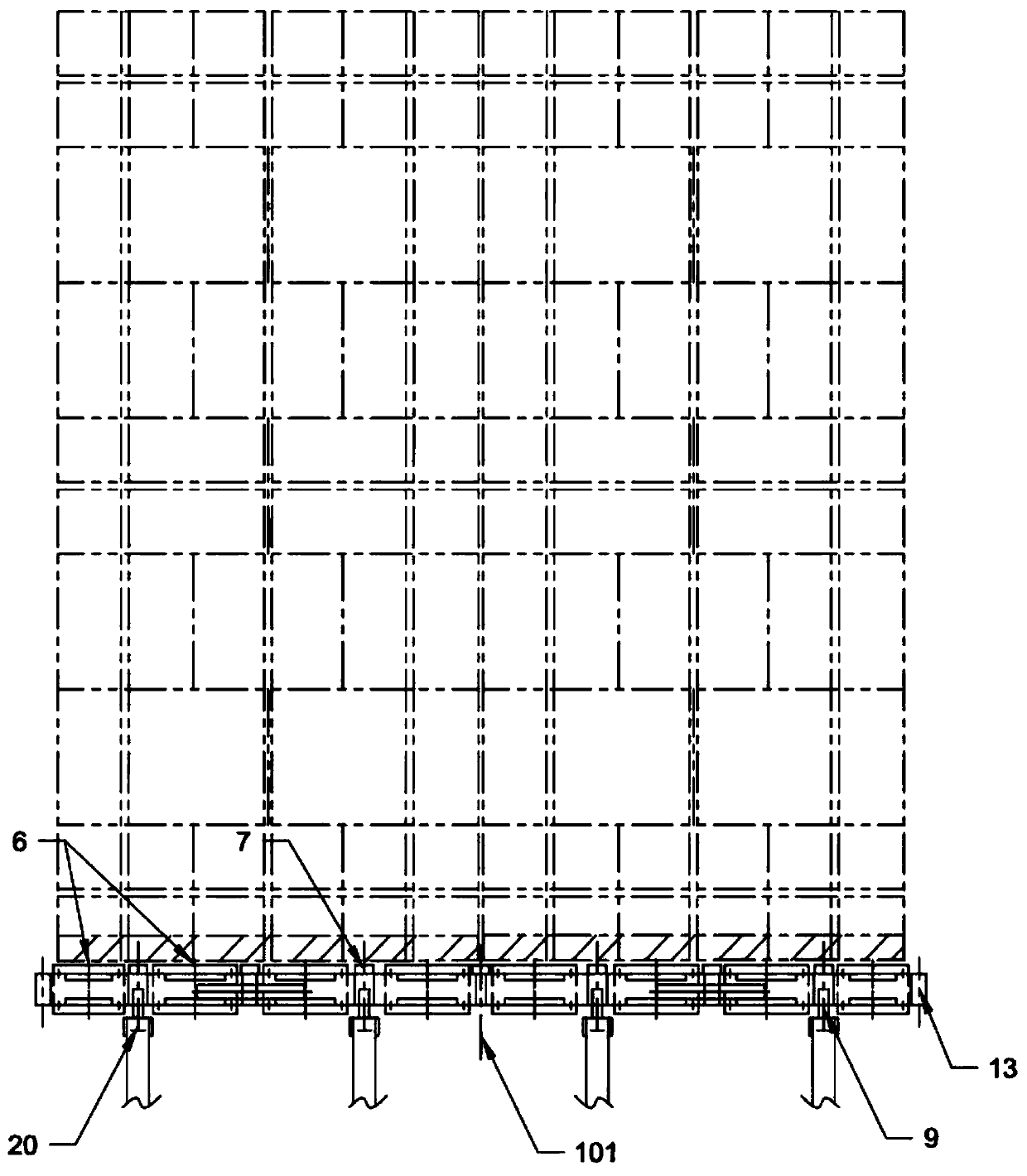

Dock basin type automated container terminal loading and unloading operation system and operation method

ActiveCN105621264BImprove the efficiency of loading and unloading operationsImprove economyTrolley cranesEngineeringYard

The invention discloses a harbor basin type automatic container wharf loading and unloading operation system. The harbor basin type automatic container wharf loading and unloading operation system is composed of a harbor basin rail type gantry crane, a striding transporting vehicle and yard rail-mounted gantry cranes. A ship berths in a harbor basin. The two sides of the harbor basin are each paved with one rail. Two door legs of the crane are supported on the rails, and the crane walks on the harbor basin and is responsible for the container loading and unloading operation of the ship. Container stacking areas are arranged below cantilever structures at the two ends of the crane, and a hatchway cover stacking area is arranged below one end of the crane. Container yards are arranged on the two edges of the harbor basin and are perpendicular to the harbor basin. The yard rail-mounted gantry cranes are arranged on the container yards to be responsible for the loading and unloading operation of containers. The invention further discloses an operation method of the harbor basin type automatic container wharf loading and unloading operation system. The loading and unloading operation efficiency of the container ship is improved, the horizontal transportation vehicle flow structure is optimized, the berthing time of the container ship in a harbor is shortened, and therefore the competitive power and radiometric force of a wharf are improved.

Owner:CCCC THIRD HARBOR CONSULTANTS

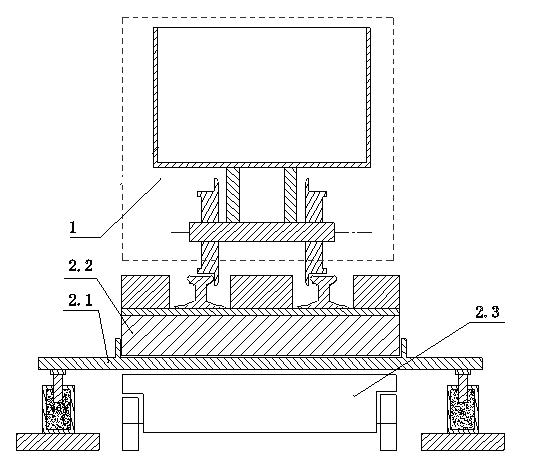

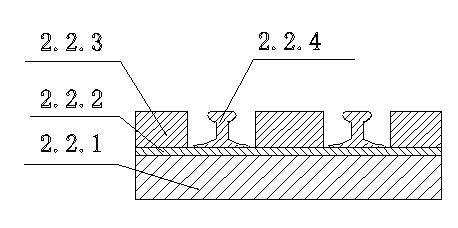

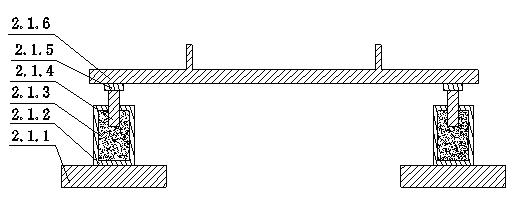

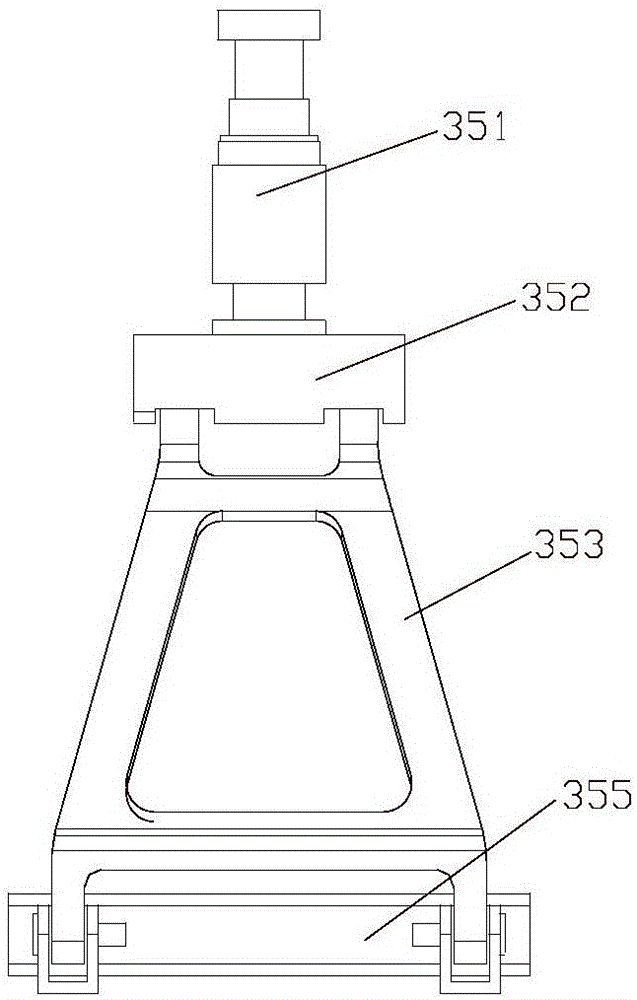

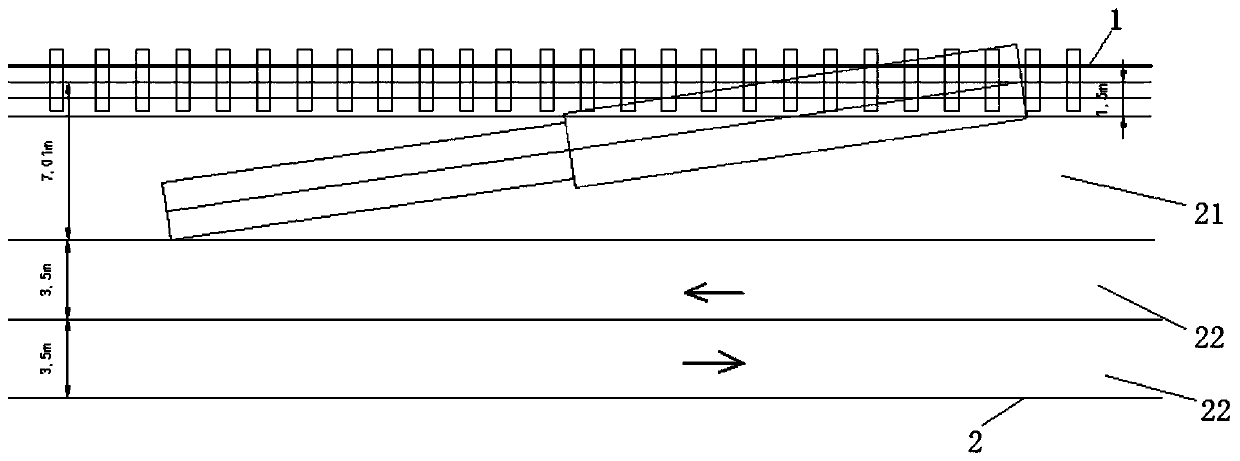

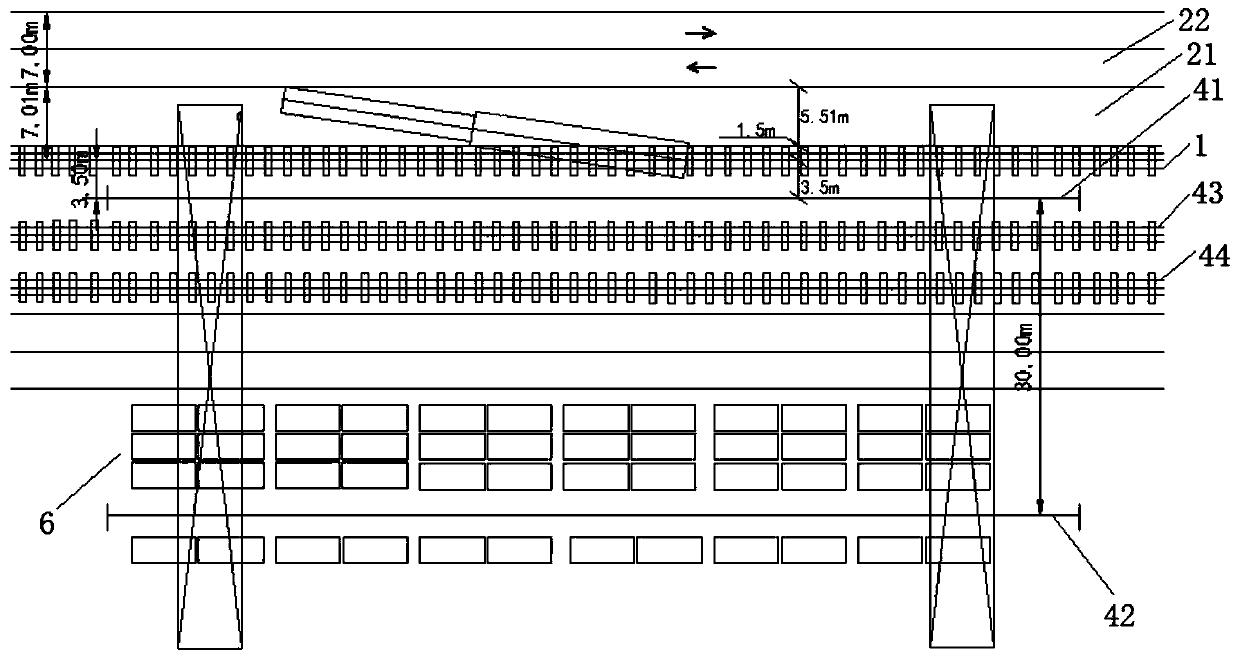

Railway piggyback transportation station foundation structure

PendingCN110745571AImprove the efficiency of loading and unloading operationsImprove transportation efficiencyStorage devicesArchitectural engineeringStructural engineering

The invention discloses a railway piggyback transportation field station foundation structure. The railway piggyback transportation station foundation structure comprises railway loading and unloadingrails and piggyback working areas which are arranged side by side, wherein the ground foundation of the piggyback working areas is subjected to hardening treatment according to the bearing strength of a highway truck which can bear the total weight of 60 tons and the single axle load of 11.5 tons, the hardened ground is formed, and the height difference between the hardened ground of the piggyback working areas and the upper plane of steel rail bodies of the railway loading and unloading rails is controlled within + / -50 mm; and the distance between the edges, near the railway loading and unloading rails, of the hardened ground of the piggyback working areas and the center line of the railway loading and unloading rails is not less than 1.5 m, and the distance between the edges, far away from the railway loading and unloading rails, of the piggyback working areas and the center line of the railway loading and unloading rails is not less than 7.01 m. By the adoption of the railway piggyback transportation field station foundation structure, the whole column loading and unloading operation efficiency can be improved by about 200%, the operation time can be effectively saved, the siteutilization rate is high, and the transportation efficiency can be improved by more than 30%.

Owner:CHINA RAILWAY SIYUAN SURVEY & DESIGN GRP

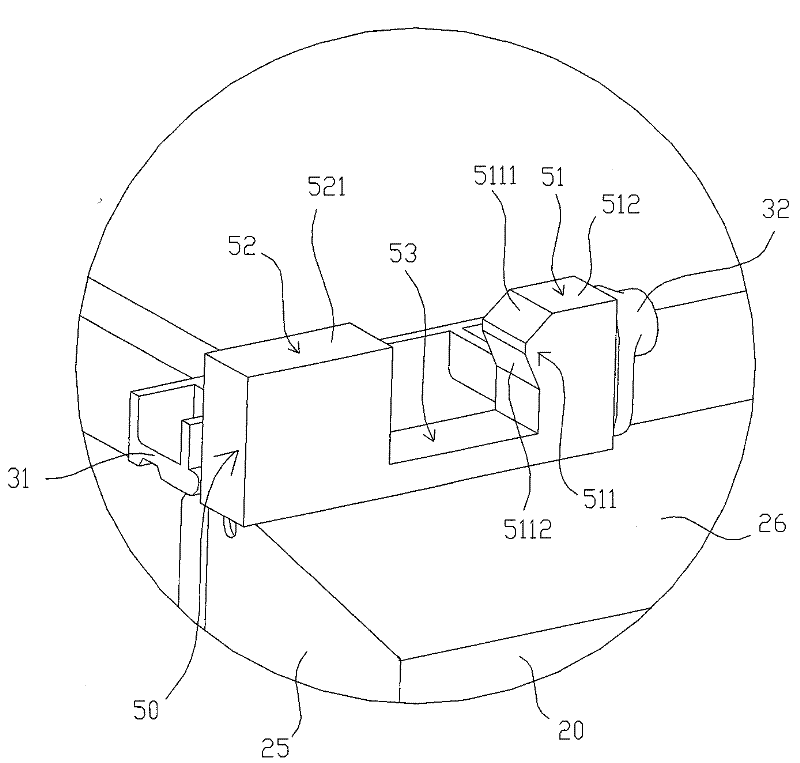

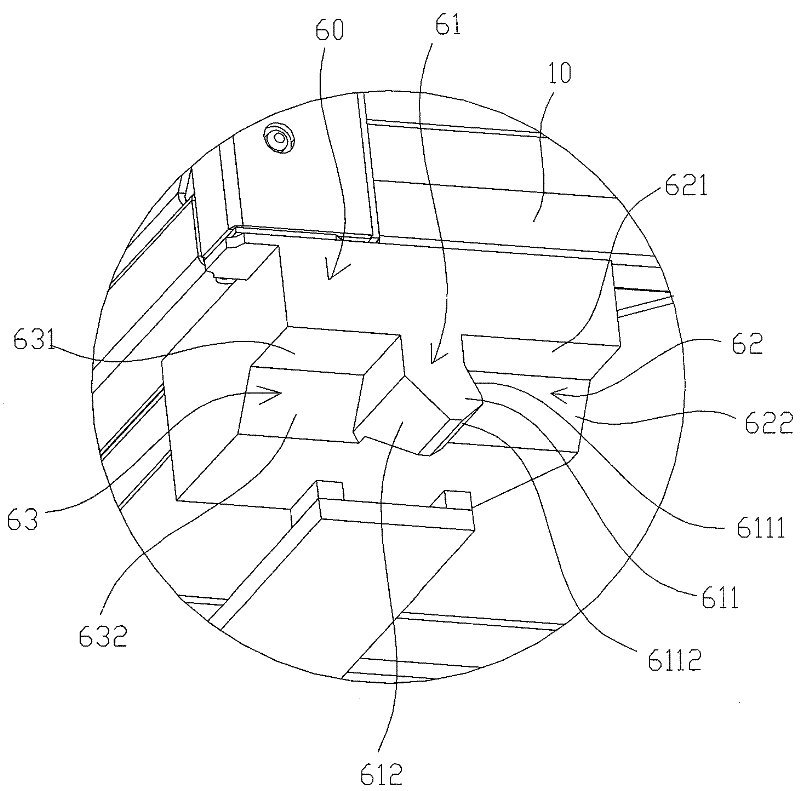

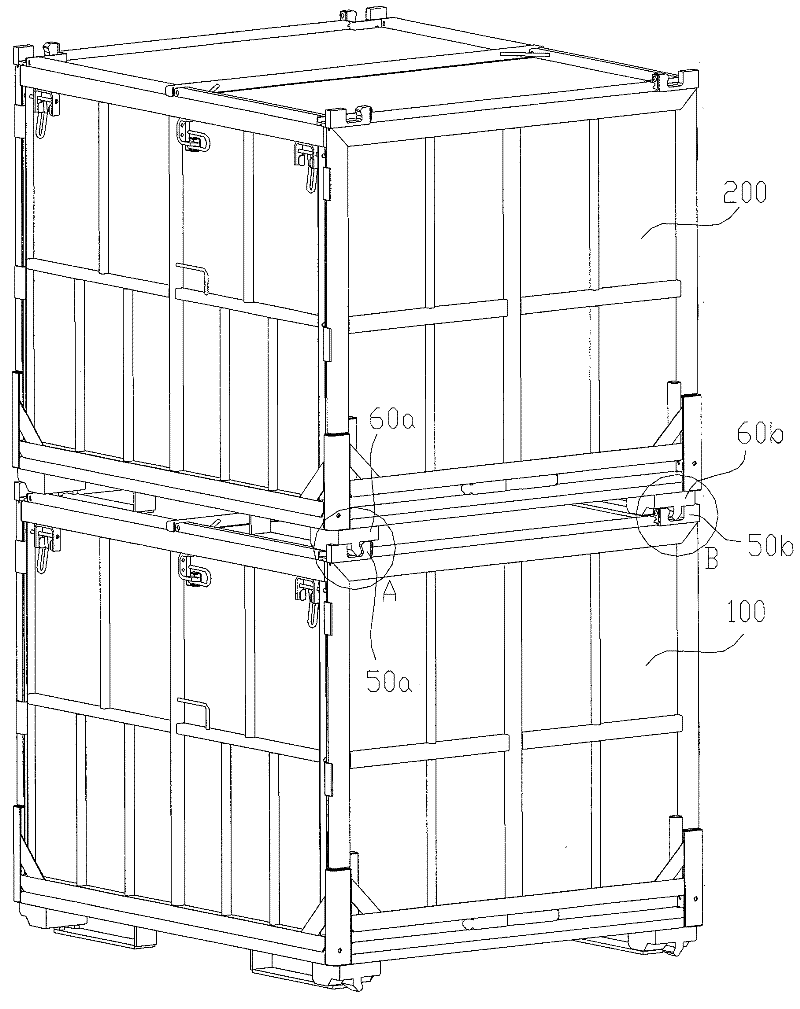

Tray box

The invention relates to a tray box at least comprising a chassis and four sidewalls. The four sidewalls are opposite in pairs and are vertically arranged on four sides of the chassis to form the tray box at a vertical arrangement state. Four corners of the top of the tray box are provided with four top pile connecting pieces connected with the lower ends of the sidewalls, each top pile connecting piece at least comprises a first hook and a first pile space, the first hook is provided with a first hook head protruding from the box outwards, and the first pile space is arranged at one side outside the box. Four corners of the bottom of the tray box are provided with four bottom pile connecting pieces corresponding to the top pile connecting pieces, each bottom pile connecting piece at least comprises a second hook and a second pile space, the second hook is provided with a second hook head protruding from the box inwards, and the second pile space is arranged at one side inside the box. The piling of two tray boxes is realized by the cooperation of the top pile connecting pieces and the bottom pile connecting pieces, and the tray box at the upper layer can be prevented from tippingby the upper and lower matched hooking of the first hook heads and the second hook heads.

Owner:CHINA INTERNATIONAL MARINE CONTAINERS (GROUP) CO LTD +2

Loading and unloading robot

InactiveCN109081102AReduce consumptionReduce production pressureConveyor partsEngineeringMechanical engineering

The invention discloses a loading and unloading robot comprising a longitudinal movement mechanism, a traverse movement mechanism and an air claw. The longitudinal movement mechanism comprises a bracket, a longitudinal movement motor, a lead screw and a longitudinal movement block; the longitudinal movement motor is located outside the bracket and is connected to the top end of the bracket througha motor fixing plate, the lead screw is connected to a rotating shaft of the longitudinal movement motor through a gear transmission mechanism, and the longitudinal movement block is connected to thelead screw through a sleeve; the traverse movement mechanism includes a traverse movement motor, a traverse movement block and a belt transmission mechanism; the traverse movement motor is connectedto the longitudinal movement block through a connecting block, one side of the traverse movement block is provided with a movable slide rail, the movable slide rail is connected to the end surface ofa rotating shaft of the traverse movement motor through a fixed slider, and the belt transmission mechanism is connected to the rotating shaft of the traverse movement motor through a rotating wheel;and the air claw is located at one end of the traverse movement block. The loading and unloading robot can quickly carry out the loading and unloading operation, improves the efficiency, reduces the cost consumption, and reduces the production pressure of an enterprise.

Owner:昆山晨鼎嘉电子科技有限公司

Flexible loading and unloading mobile platform and its purpose and method of use

ActiveCN110092219BImprove flexibilityContinuous and efficient mobile conveyingLoading/unloadingStructural engineeringMechanical engineering

The invention discloses a flexible loading and unloading mobile platform and purposes and an application method thereof. The flexible loading and unloading mobile platform comprises a platform foundation component, a platform driving assembly, a bulldozing mechanism and a conveying assembly. The platform foundation component comprises an inclined section plate assembly and a flat section plate assembly which are flexibly connected from front to back in sequence. The flatform driving assembly is connected with the flatform foundation component and a unit cargo integration loading and unloadingoperating vehicle or an underpan, and drives the platform foundation component to reciprocate relative to the unit cargo integration loading and unloading operating vehicle or the underpan. The bulldozing mechanism is arranged below the platform foundation component and used for converting an upper operating surface of the inclined section plate assembly between an inclined surface state and a flat surface state. The conveying assembly is arranged on the flat section plate assembly and reciprocates relative to the flat section plate assembly. When being used, the flexible loading and unloadingmobile platform is arranged on the unit cargo integration loading and unloading operating vehicle or the underpan, a whole vehicle of integrated unit cargoes are loaded and unloaded integrally.

Owner:广州绿茵无垠科技有限公司

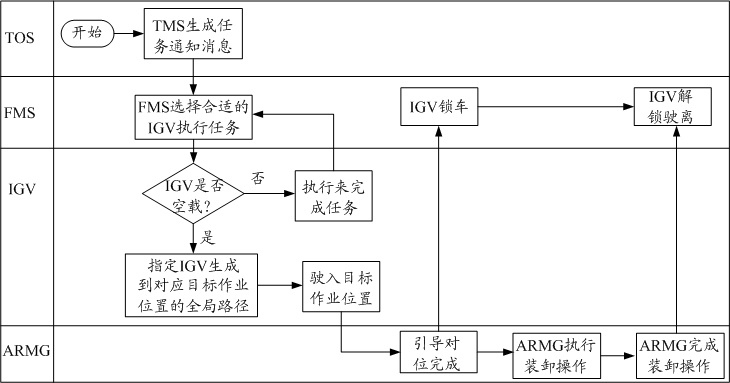

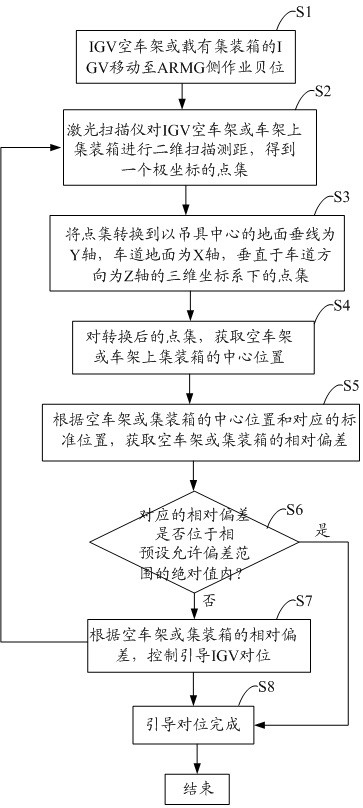

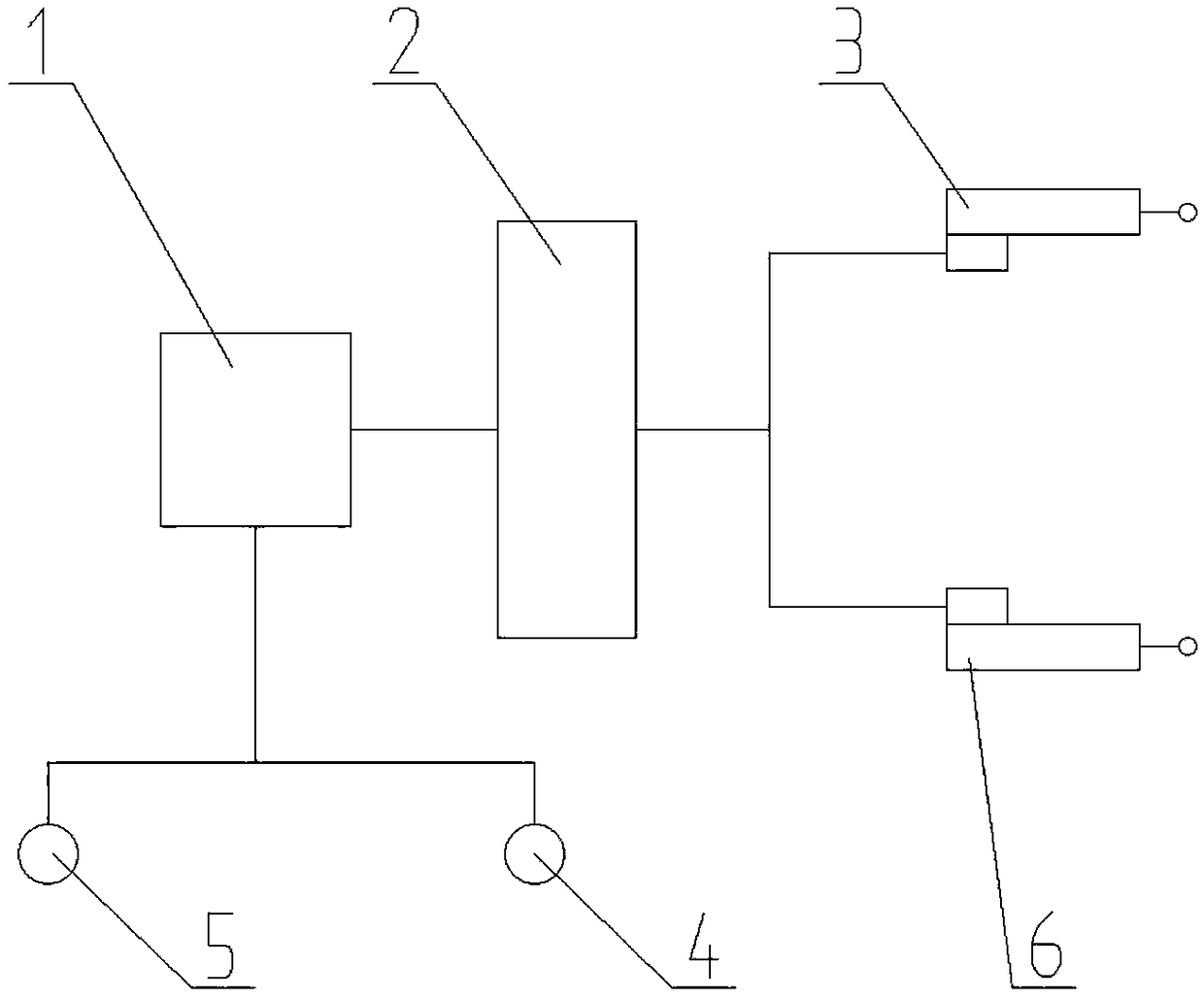

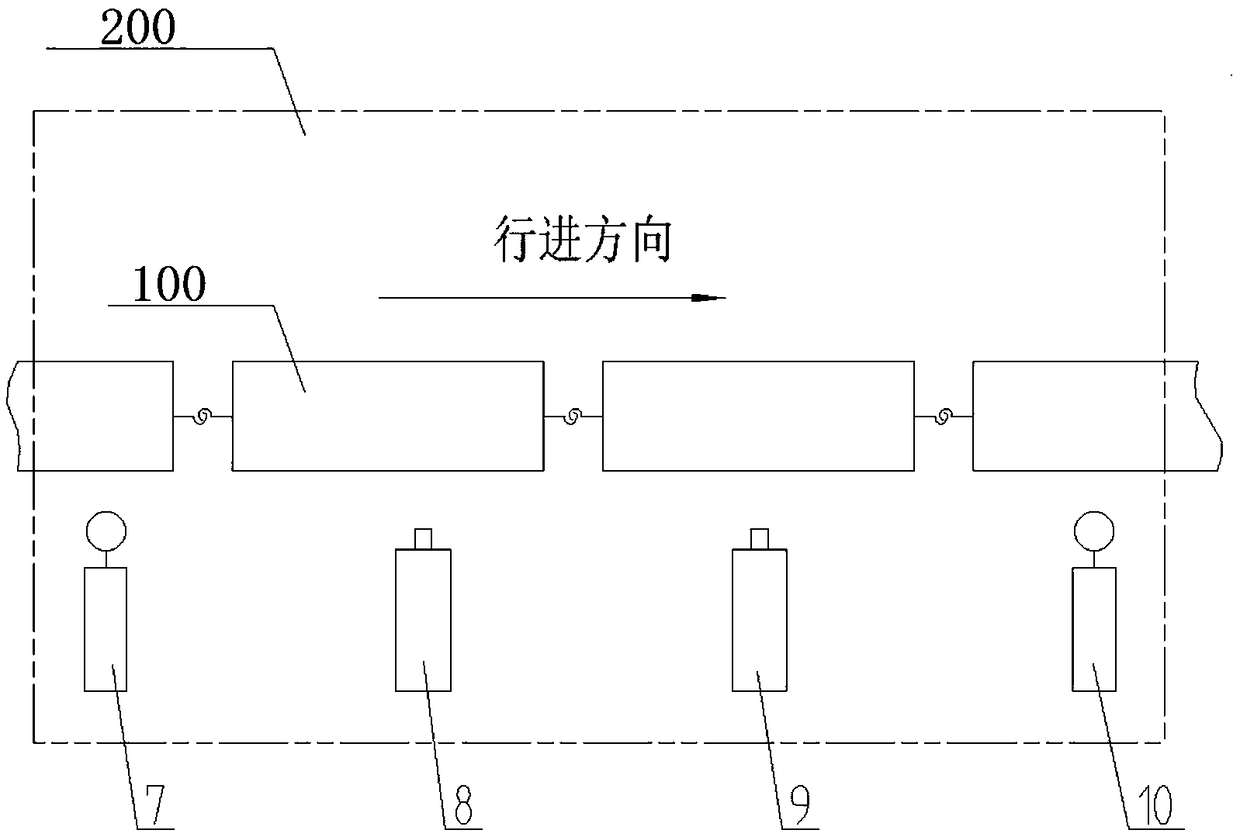

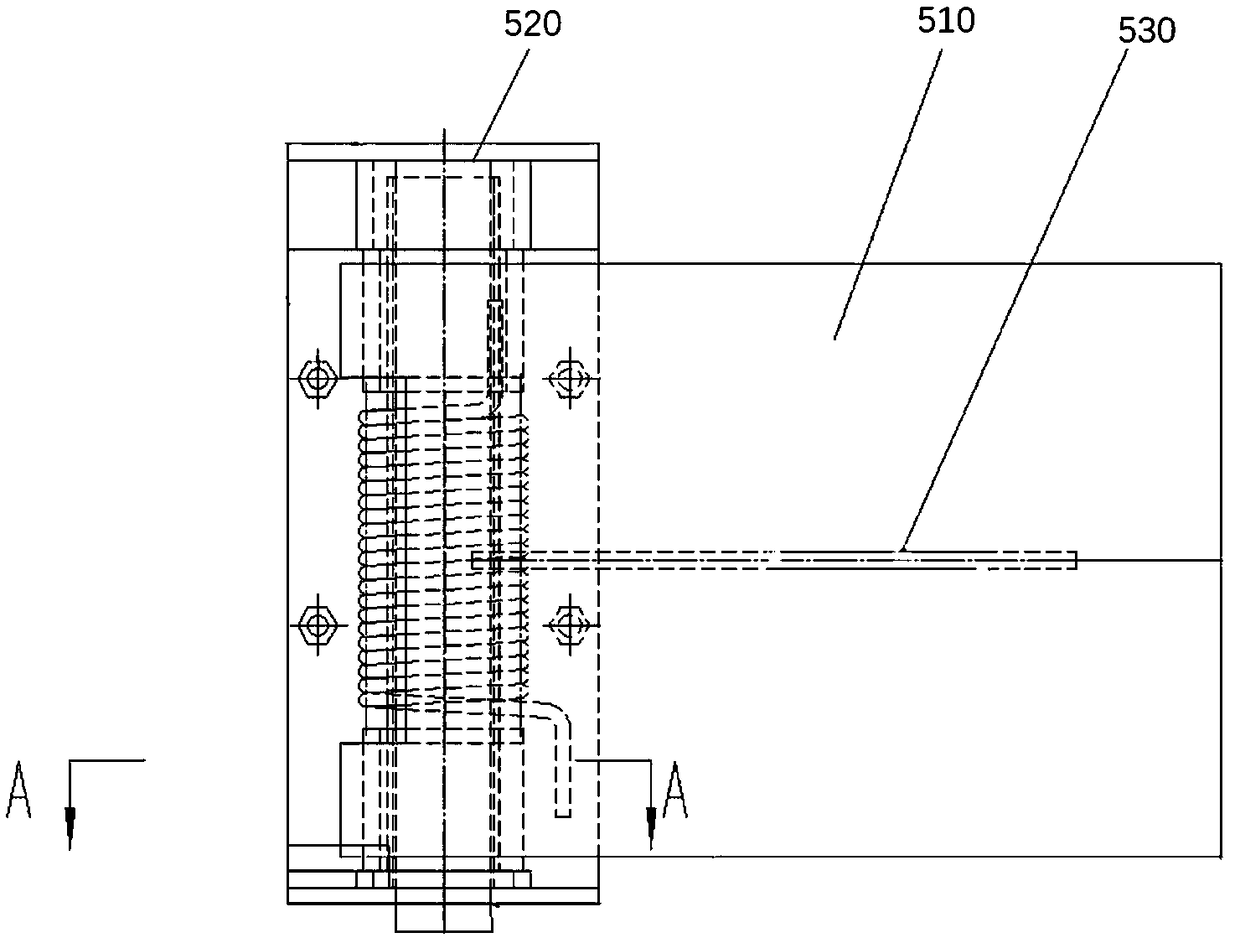

IGV and ARMG automatic guiding alignment method and system

PendingCN114852865AReliable alignmentAccurateElectric/hybrid propulsionLoad-engaging elementsScannerLaser scanning

The invention discloses an IGV and ARMG automatic guiding alignment method and system. The method comprises the steps that S1, an IGV empty frame or an IGV carrying a container is moved to an ARMG side operation bay; s2, a laser scanner carries out two-dimensional scanning distance measurement on the IGV empty frame or the container on the frame, and a point set of polar coordinates is obtained; s3, converting the point set into a point set under a three-dimensional coordinate system; s4, acquiring the central position of an empty frame or a container on the frame according to the converted point set; s5, obtaining the relative deviation of the empty frame or container; s6, whether the corresponding relative deviation is within an absolute value of a preset allowable deviation range or not is judged, if yes, the step S8 is executed, and if not, the step S7 is executed; s7, according to the relative deviation of the empty frame or the container, IGV alignment is controlled and guided, and the step S2 is executed again; and S8, guiding alignment is completed. According to the invention, the IGV and ARMG alignment can be automatically, effectively and accurately realized.

Owner:QINGDAO PORT INT +1

Railway hopper car opening and closing control system and control method

ActiveCN108749832AUninterrupted continuous loading and unloading operationsEnsure personal safetyHopper carsLow speedControl system

The invention discloses a railway hopper car opening and closing control system and control method. The opening and closing control system comprises a train-mounted system used for being installed ona railway hopper car and a ground device used for being installed on a loading and unloading freight yard. Through cooperation of the train-mounted system and the ground device, when a train passes through the loading and unloading freight yard at a low speed, a top cover and / or a bottom door of the hopper car can be automatically opened and closed, the train continuously conducts freight loadingand unloading operation ceaselessly, and therefore the loading and unloading operation efficiency is improved.

Owner:BAOTOU NORTH VENTURE

A movable pedal board

InactiveCN103204393BSolve problems that cannot pass and work effectivelySolve loading and unloading problemsLoading/unloadingHeight differenceLoading unloading

The invention discloses a mobile movable boarding cap apron which comprises an upper movable platform, a base and a lifting support leg. The lower side of the upper movable platform is connected with the base through a rotary shaft structure. The upper platform can obliquely turns at angles to a horizontal face on the base and around the rotary shaft structure. The lifting support leg is connected between the movable platform and the base to driving the upper movable platform to turn obliquely. The mobile movable boarding cap apron is matched with a storeroom loading and unloading platform and a transport vehicle to solve the problem that a fork lift cannot pass for effective operation when height difference between the loading and unloading platform and the transport vehicle is excessive. The mobile movable boarding cap apron utilizes a steel oblique plate structure lapped between the transport vehicle and the loading and unloading platform, the fork lift can load and unload goods in batches, and matching of the loading and unloading platform 07-1.5m in height with the transport vehicle and fork lift loading unloading are achieved. The mobile movable boarding cap apron has the advantages that the mobile movable boarding cap apron is capable of moving by dragging, adjusting height and automatically locking, and good in bearing capacity, loading and unloading efficiency of goods is improved, infrastructure reconstruction is avoided, and equipment and infrastructure investments are reduced.

Owner:ARCHITECTURAL ENG INST GENERAL LOGISTICS DEPT P L A

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com