Assembling and disassembling device for sun-cured tobacco sun-curing unit

A loading and unloading device and drying tobacco technology, applied in tobacco, tobacco preparation, application, etc., can solve the problems of low loading and unloading efficiency, slow speed, easy to produce mildew, etc., and achieve the goal of reducing docking errors, improving loading and unloading efficiency, and improving docking accuracy Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

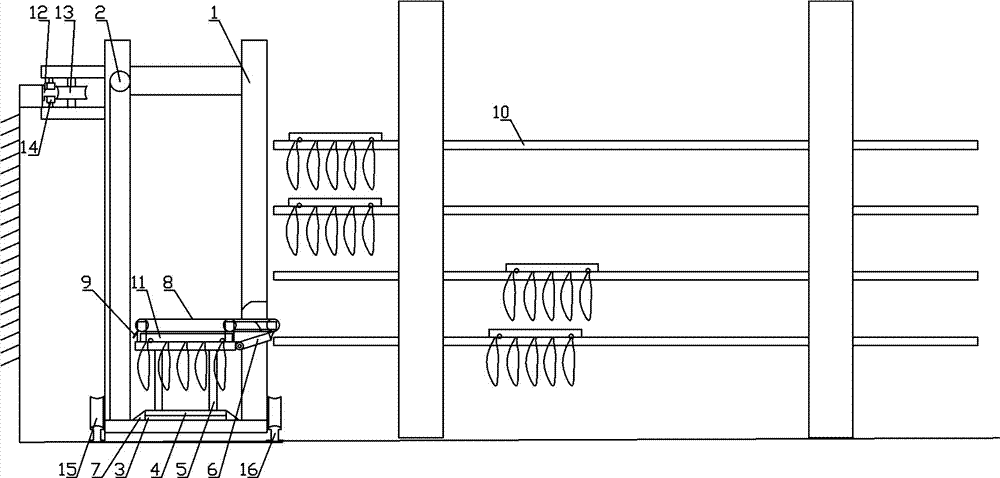

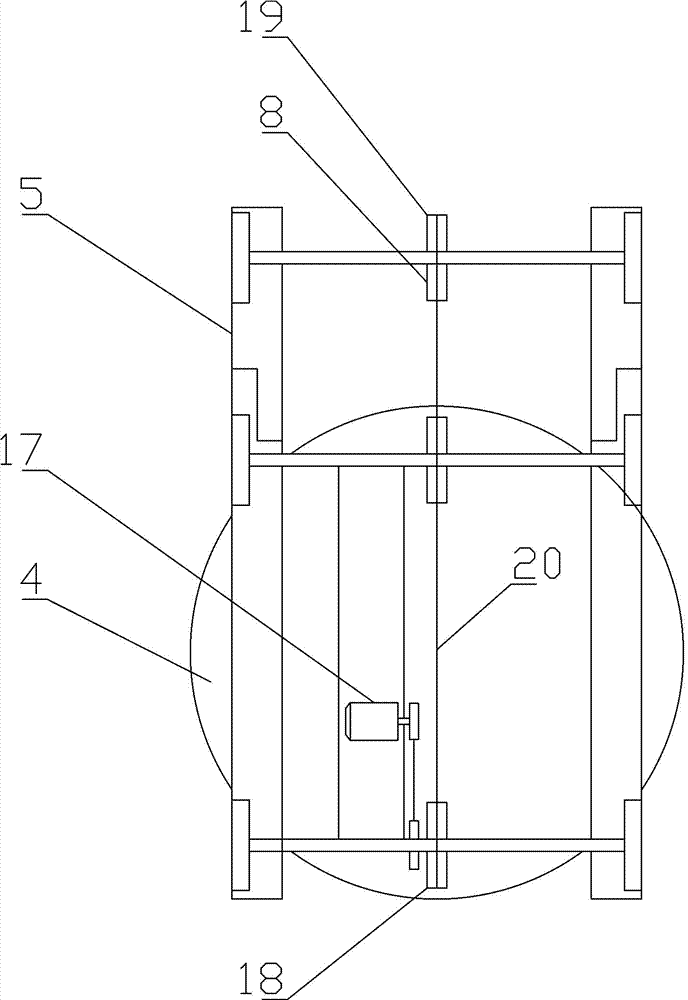

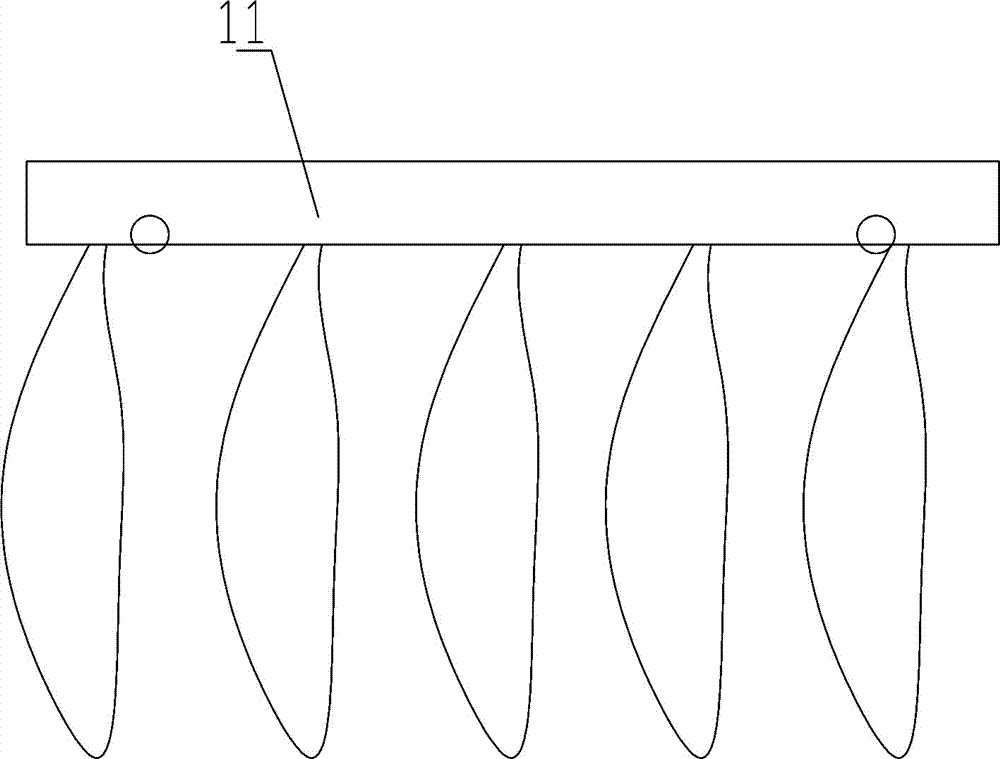

[0021] like Figure 1~3 Among them, a loading and unloading device for airing and drying tobacco, the door frame 1 is equipped with a sliding base 3 that can be lifted and lowered, the sliding base 3 is connected with the hoisting device 2, and a rotating seat 4 is installed on the sliding base 3, and the rotating seat 4 is fixed. A support 5 is provided, and an overlapping guide rail 6 is provided at the end of the support 5 close to the cigarette rack 10 , and a toggle device 8 is provided above the support 5 . With this structure, the loading and unloading of the cigarette airing unit is convenient. The tobacco airing unit 11 in this example is a frame structure, and is provided with a plurality of parallel rods, and the rods are provided with a plurality of through holes, and the tobacco airing clips are staggeredly installed in the through holes; superior. The bottom of the frame is provided with wheels to cooperate with the guide rails on the cigarette rack 10, the sup...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Rotation range | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com