Petrochemical unattended loading and unloading line digital twinning intelligent monitoring system and method

An intelligent monitoring system and twin technology, applied in the general control system, control/regulation system, program control, etc., can solve the problems of poor human-computer interaction ability, weak equipment coordination ability, and low degree of visualization, so as to improve equipment safety , Improve the efficiency of loading and unloading operations, and improve the effect of human-computer interaction capabilities

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0042]In order to illustrate the technical solutions and techniques of the present invention, the present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

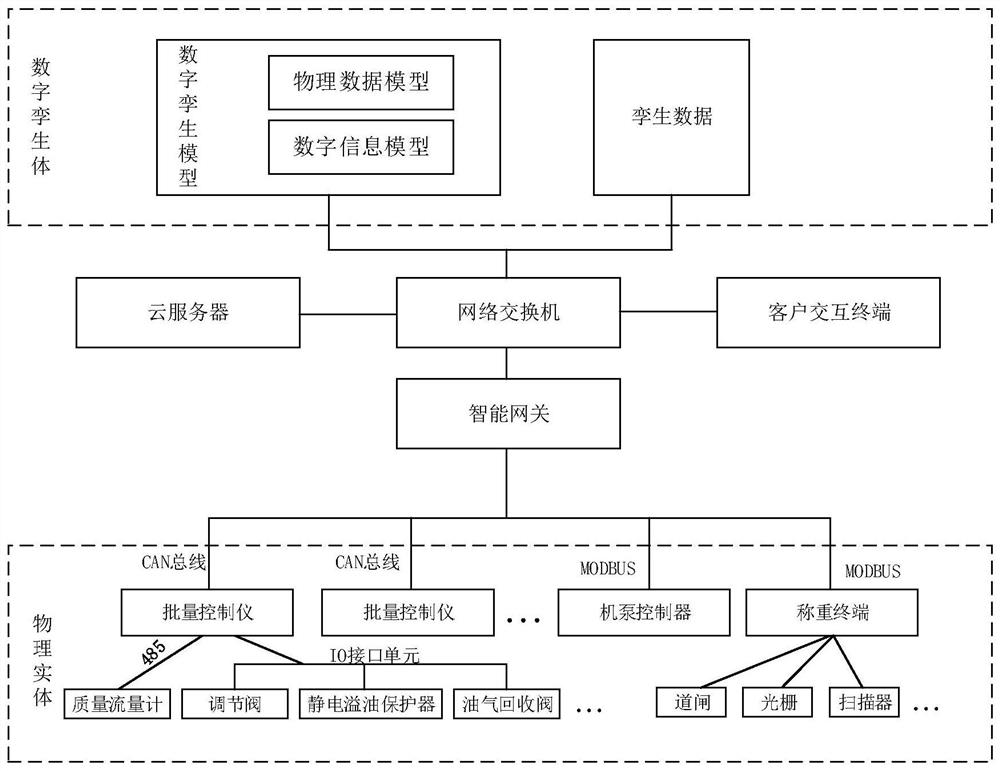

[0043]Combinefigure 1 The petrochemical unobstructed unloading line of the present invention includes physical entities, digital twins, intelligent gateways, cloud servers, network switches, and customer interaction terminals.

[0044]The physical entity not only includes a physical object such as a loading and unloading platform, a loading and unloading device, a sensor, but also includes loading and unloading tasks and loading and unloading flows. Physical loading and unloading platforms include tank areas, car balances and loading and unloading operations; tank area devices include tanks, pipes, pumps, oil and gas recovery tanks and various types of sensors, cars include car balance sensors, gratings, gratings, gates, scanners , HD cameras, loading and unloading opera...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com