Railway port transfer bulk cargo loading and unloading operation method and system

A bulk cargo handling and port technology, applied in loading/unloading, transportation and packaging, storage devices, etc., to improve loading and unloading efficiency, reduce labor costs, and improve port throughput

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] The method for loading and unloading transshipment bulk cargo at a railway port includes the following steps:

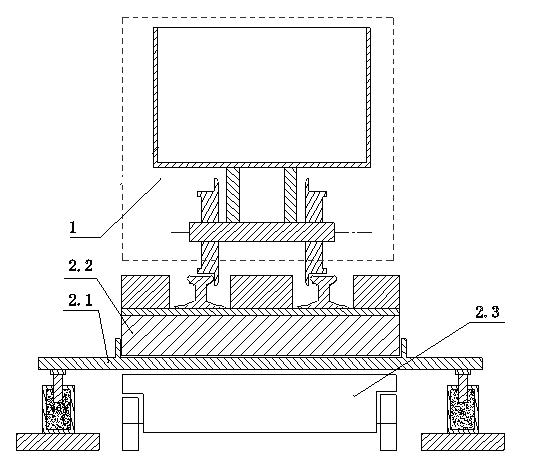

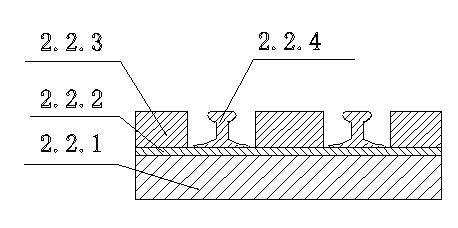

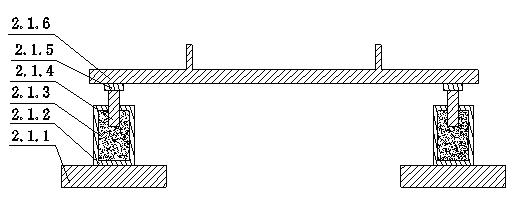

[0028] Such as figure 1 As shown, the freight car 1 of the marshalling train is pushed onto the iron transfer platform 2, and the single-section freight car 1 is loaded onto the carrier car 2.3 by using the iron loading and unloading platform 2, so that the single-section freight car 1 is independently fixed on the carrier car 2.3 According to the ownership of the goods, it is transported to the iron transfer platform 8 designated by the port freight yard 4; the bulk cargo is automatically unloaded on the iron transfer platform 8 of the freight yard, and the loading 3 is completed.

[0029] Two iron transfer platforms 2, 8 are used in the described operation, and the iron transfer platform 2 is arranged in the railway freight yard 5, and is used for the single section freight car compartment 1 to load the carrier vehicle 2.3 from the railway track, or to load...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com