Double-jaw grab bucket device of crane

A crane and jaw plate technology, which is applied in the field of double-jaw plate grab device for loading and unloading mineral powder particles with high water content. The effects of working efficiency, reducing friction coefficient, and convenient operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

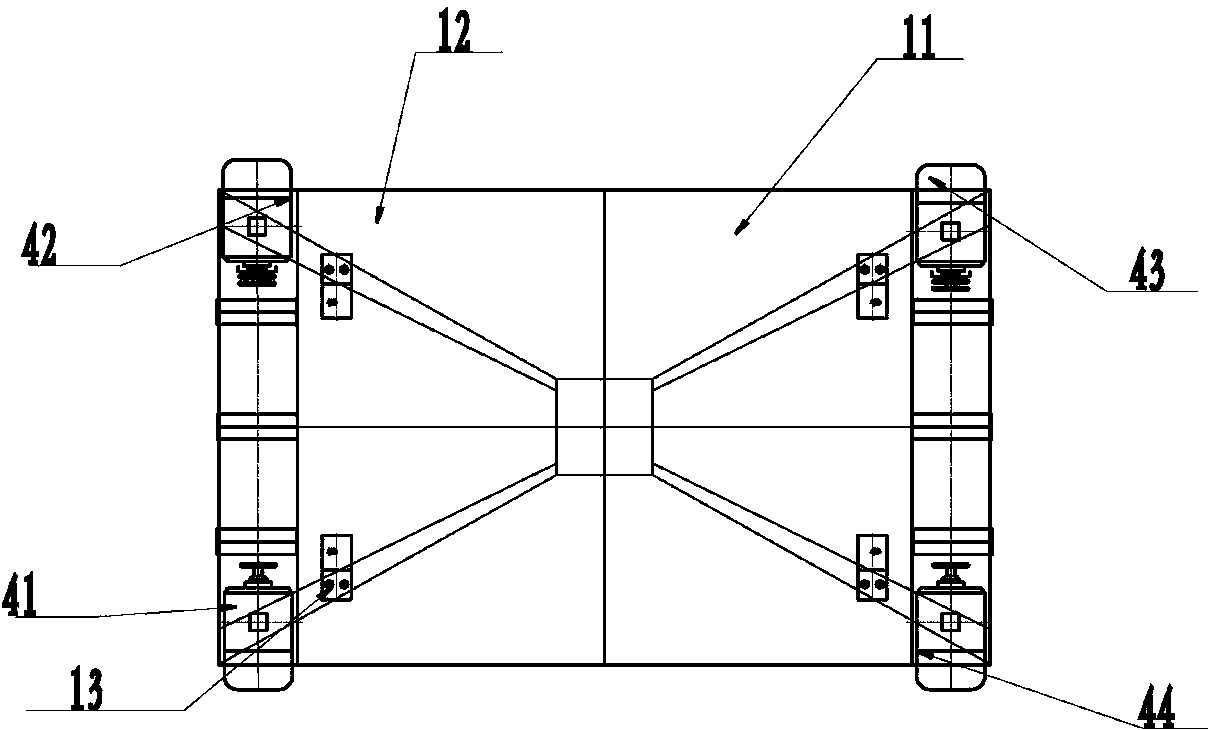

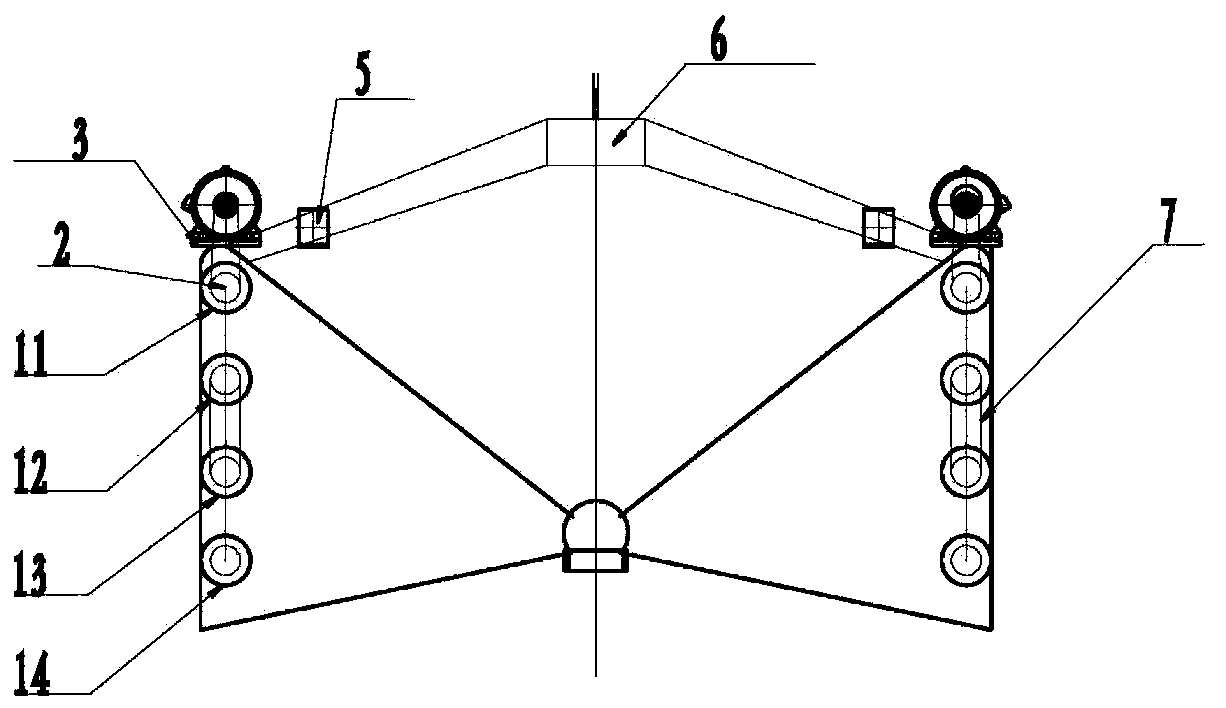

[0017] Referring to accompanying drawing, left jaw plate 18 has four roller bars groups, and right jaw plate also has four roller bars sets, and left and right jaw plate structure and power transmission mode are identical.

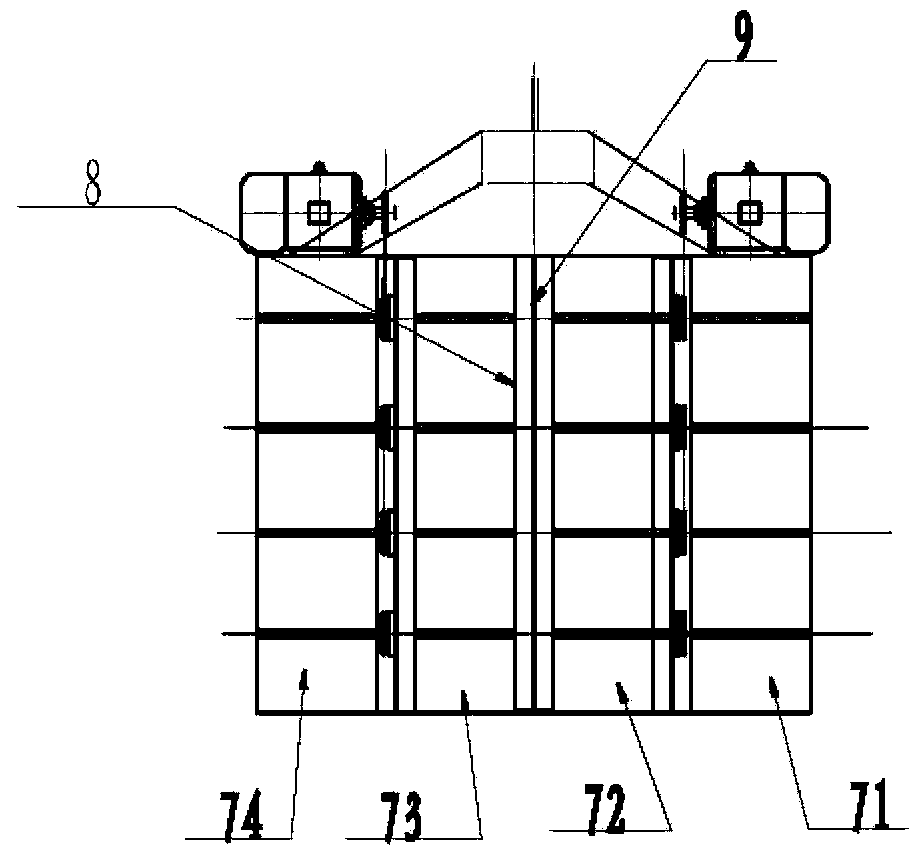

[0018] Right jaw plate 17 and left jaw plate 18 tops are respectively equipped with two motors, totally four motors, battery supporting plate 13 is fixed on the grab lifting device 6, battery 5 is installed on the battery supporting plate 13, four batteries 5 respectively Provides power to four motors. Battery 5 is a portable power supply, fixed on the grab bucket top, powered by a DC battery pack, and needs to be replaced and charged regularly.

[0019] Each motor drives two adjacent roller groups, each roller group has four rollers, each roller group of left jaw plate 18 includes roller 11, roller 12, roller 12, roller 14; right ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com