Novel cargo box of engineering vehicle

A technology of engineering vehicles and cargo boxes, which is applied in the direction of tilted load-carrying vehicles, etc., can solve the problems of inconvenient loading and unloading of cargo, insufficient load of the cargo box, and insufficient maximum load of the chassis of the cargo box, etc., to achieve convenient cargo unloading and strong environmental adaptability , The effect of improving the efficiency of loading and unloading operations

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

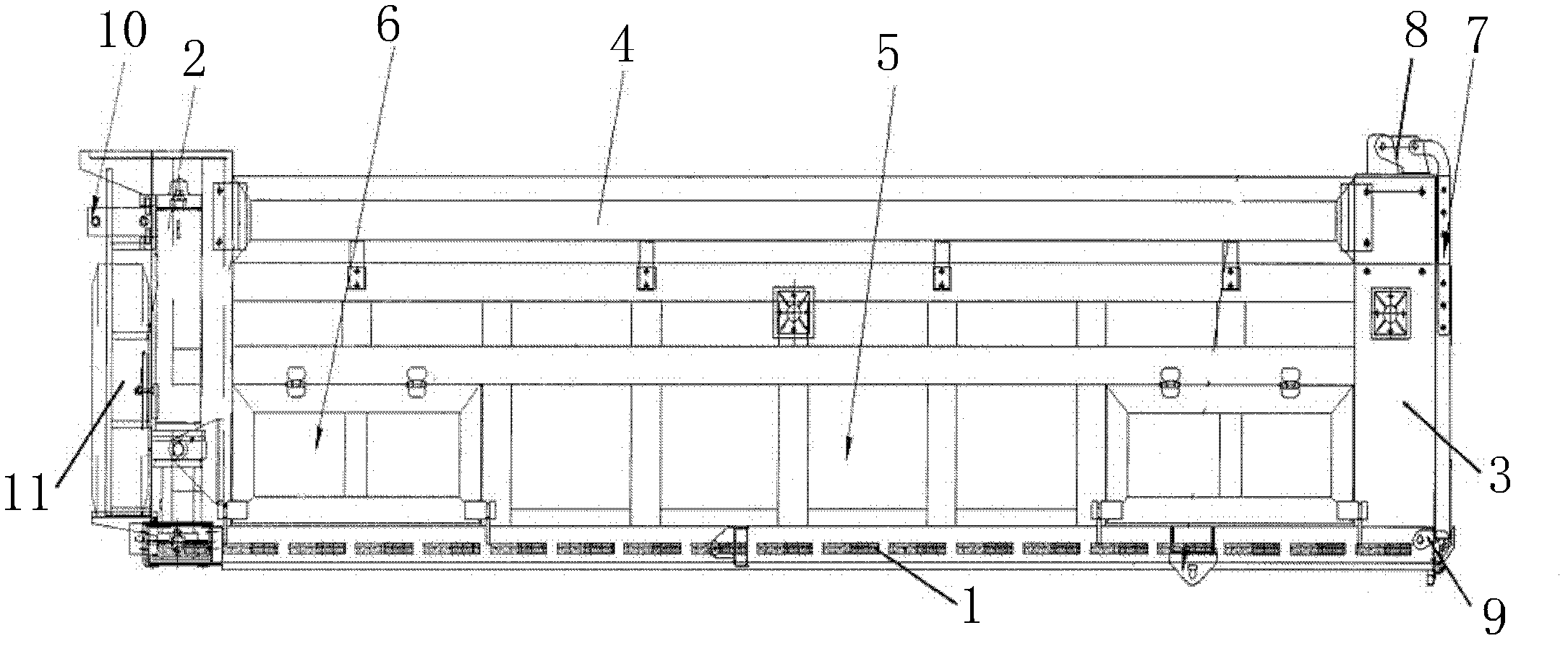

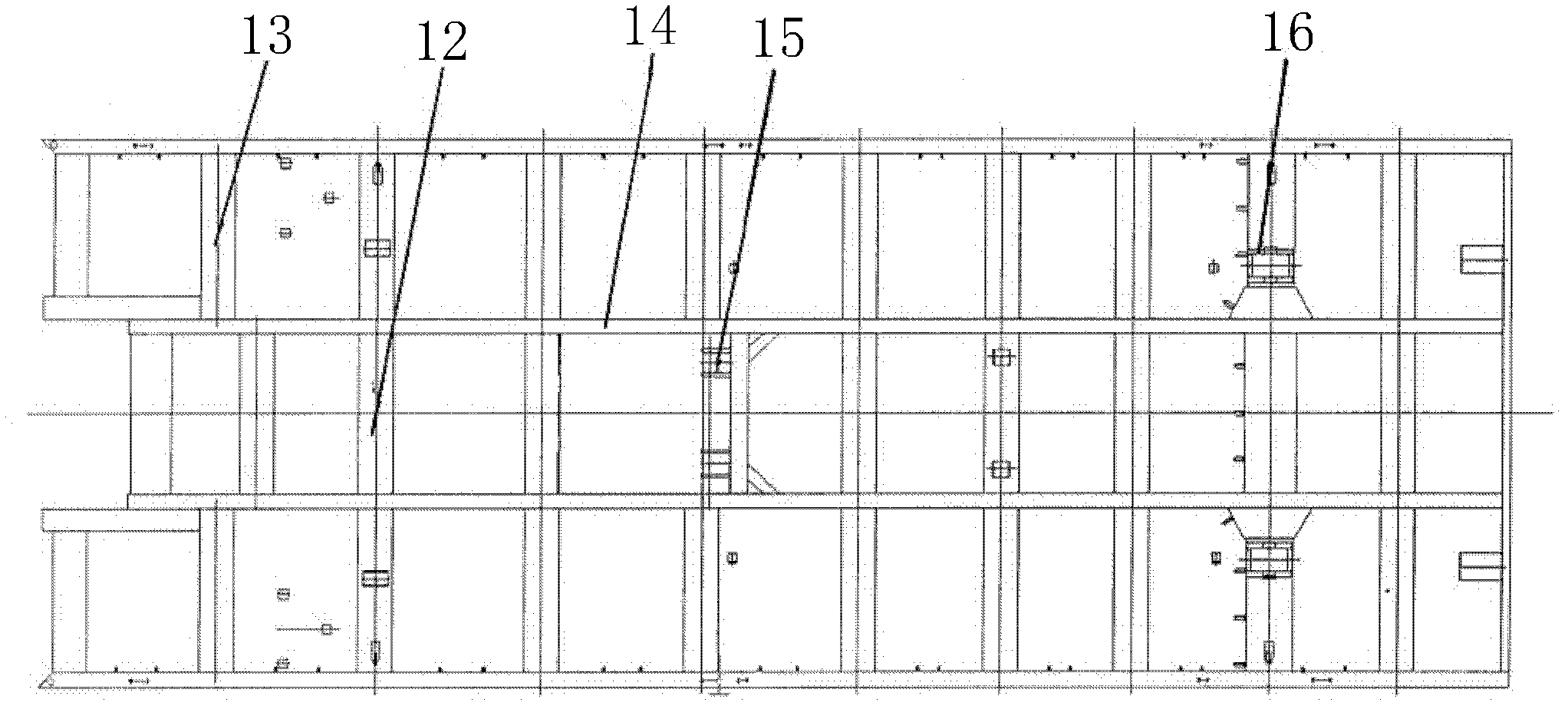

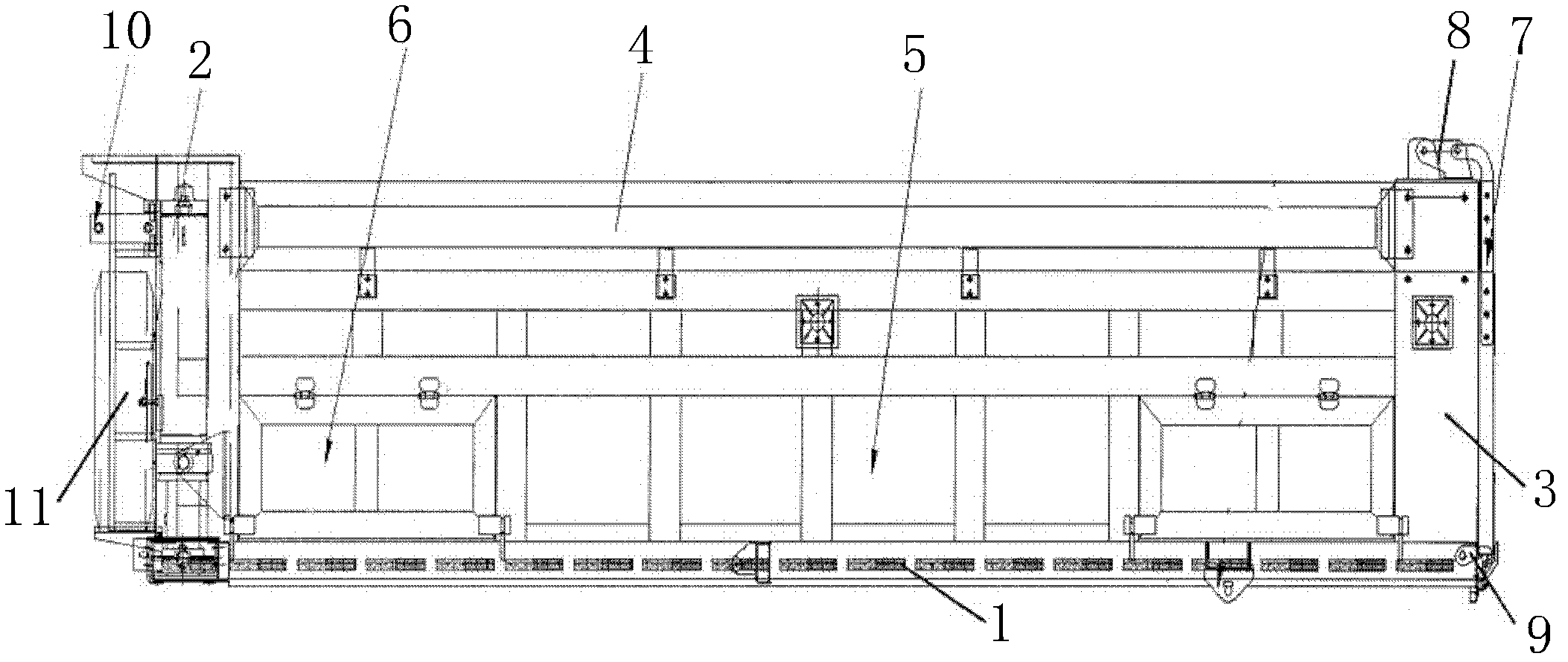

[0010] Such as figure 1 , 2 As shown, the present invention is respectively provided with front column 2 and rear column 3 at both ends of chassis 1, is connected with upper side plate 4 and lower side plate 5 between front column 2 and rear column 3, and the lower edge of described lower side plate 5 Connected with the edge of the chassis 1, small doors 6 are respectively provided at both ends of the lower side plate 5, the rear side plate 7 is set on the rear column 3 through the lifting lug 8, the hook 9 hangs the rear side plate 7 together, the wire rope rack 10 and the spare tire The frame 11 is arranged on one side of the front column 2, and the chassis 1 is composed of a plurality of beams 12, side beams 13 and longitudinal beams 14, and the oil cylinder balance support 15 and the turning seat 16 are respectively arranged in the middle part and the middle of the rear end of the base 1. parts. Through the above settings, the present invention ensures that the chassis c...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com