Container crane with double pitching mechanisms and loading and unloading method of container crane

A technology of container crane and pitching mechanism, which is applied in the direction of crane, crane, transportation and packaging of trolleys, can solve the problems of large eccentric load of the whole machine structure, long operation period and reduced operation efficiency, and achieves good economy and practicability. , Improve the efficiency of loading and unloading operations, and improve the effect of working efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

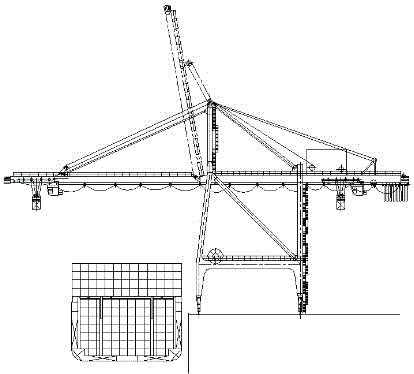

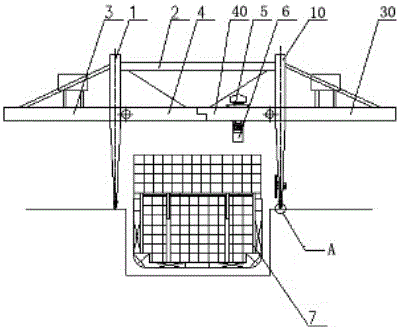

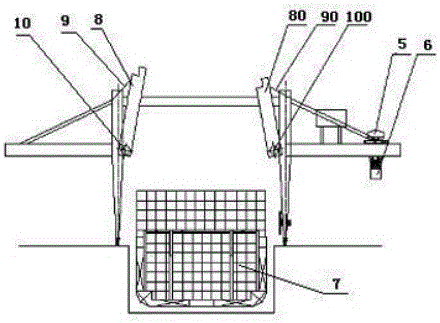

[0024] see figure 2 , image 3 and Figure 4 , a kind of container crane with double pitching mechanism of the present invention consists of a left mast structure 1, a right mast structure 10, a beam structure 2, a left rear girder structure 3, a right rear girder structure 30, a left pitching mechanism 4, and a right pitching mechanism 40, trolley traveling mechanism 5, spreader lifting mechanism 6, left cart traveling mechanism 20 and right cart traveling mechanism 11 form.

[0025] The beam structure 2 is connected between the left and right door frame structures 1, 10 to form a whole. The left and right cart running mechanisms 20, 11 are correspondingly arranged under the left and right mast structures 1, 10, and the left and right cart running mechanisms 20, 11 are arranged on the left track and the right track 12 on both sides of the container ship 7 , can walk along the left track and the right track 12.

[0026] The left pitching mechanism 4 is composed of a left ...

Embodiment 2

[0033] The loading and unloading method of the container crane is as follows: the container crane straddles the container ship 7, before the container ship 7 enters, the trolley running mechanism 5 and the spreader lifting mechanism 6 are parked on the right rear beam structure 30, and the left and right pitching mechanisms 4 , 40 respectively pull up the left and right front girder structures 8, 80 through the left and right wire rope winding systems 9, 90, and the included angles are each in a state of 80°; after the container ship 7 stops, the left and right pitching mechanisms 4, 40 Level the left and right front frame structures 8, 80 through the left and right steel wire rope winding systems 9, 90, so that the left and right front frame structures 8, 80 and the left and right rear frame structures 3, 30 maintain the same horizontal plane, and then lift by the spreader Mechanism 6 loads and unloads containers.

[0034] A container crane with two sets of pitching mechanism...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com