Centering device for positioning sheet material in automatic punching line

An automatic line and centering platform technology, applied in the direction of positioning device, feeding device, storage device, etc., can solve the problem of difficult positioning of special-shaped sheet metal, to overcome the easily damaged edge of the sheet metal, to facilitate automation, and to beat the impact force small Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

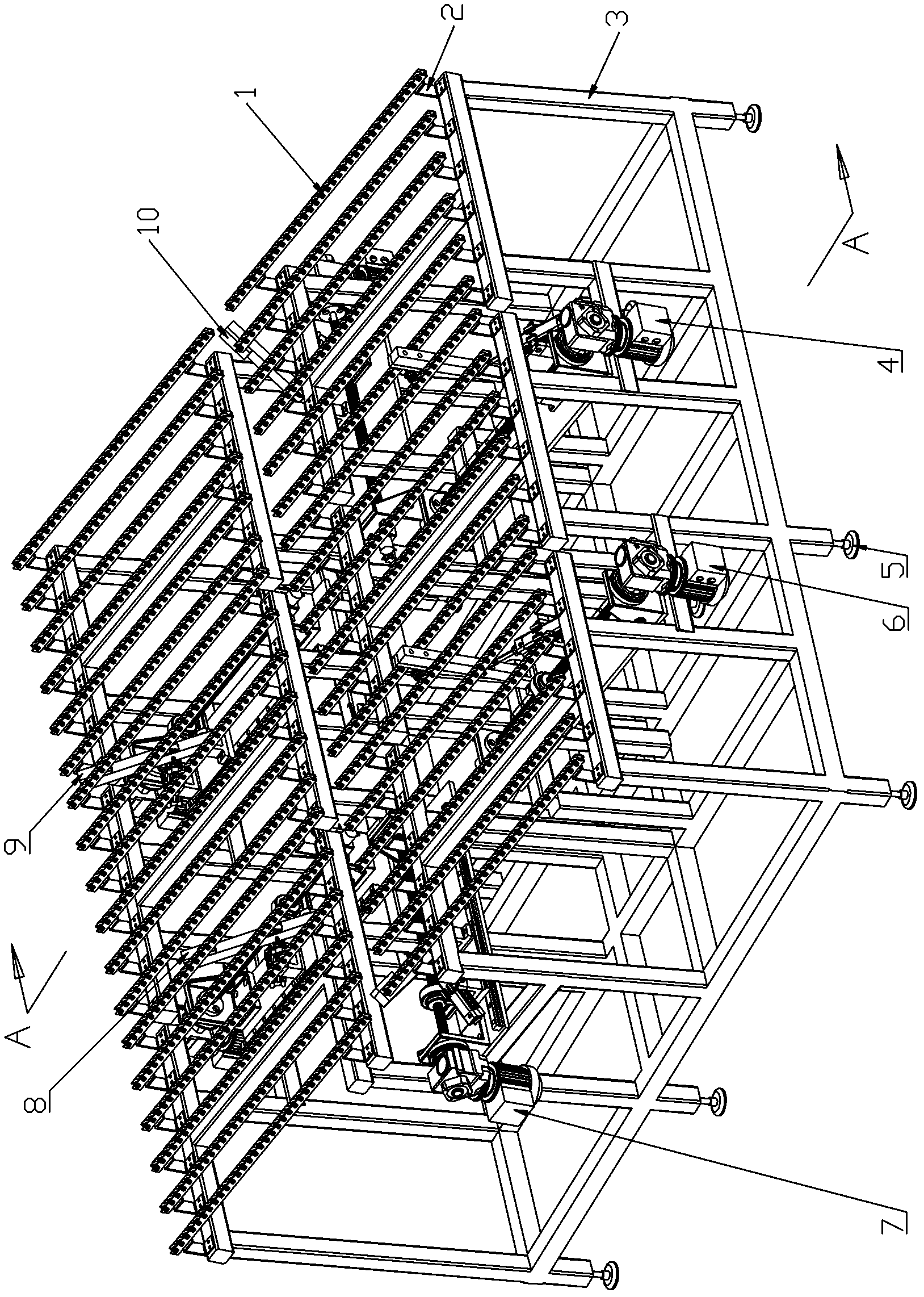

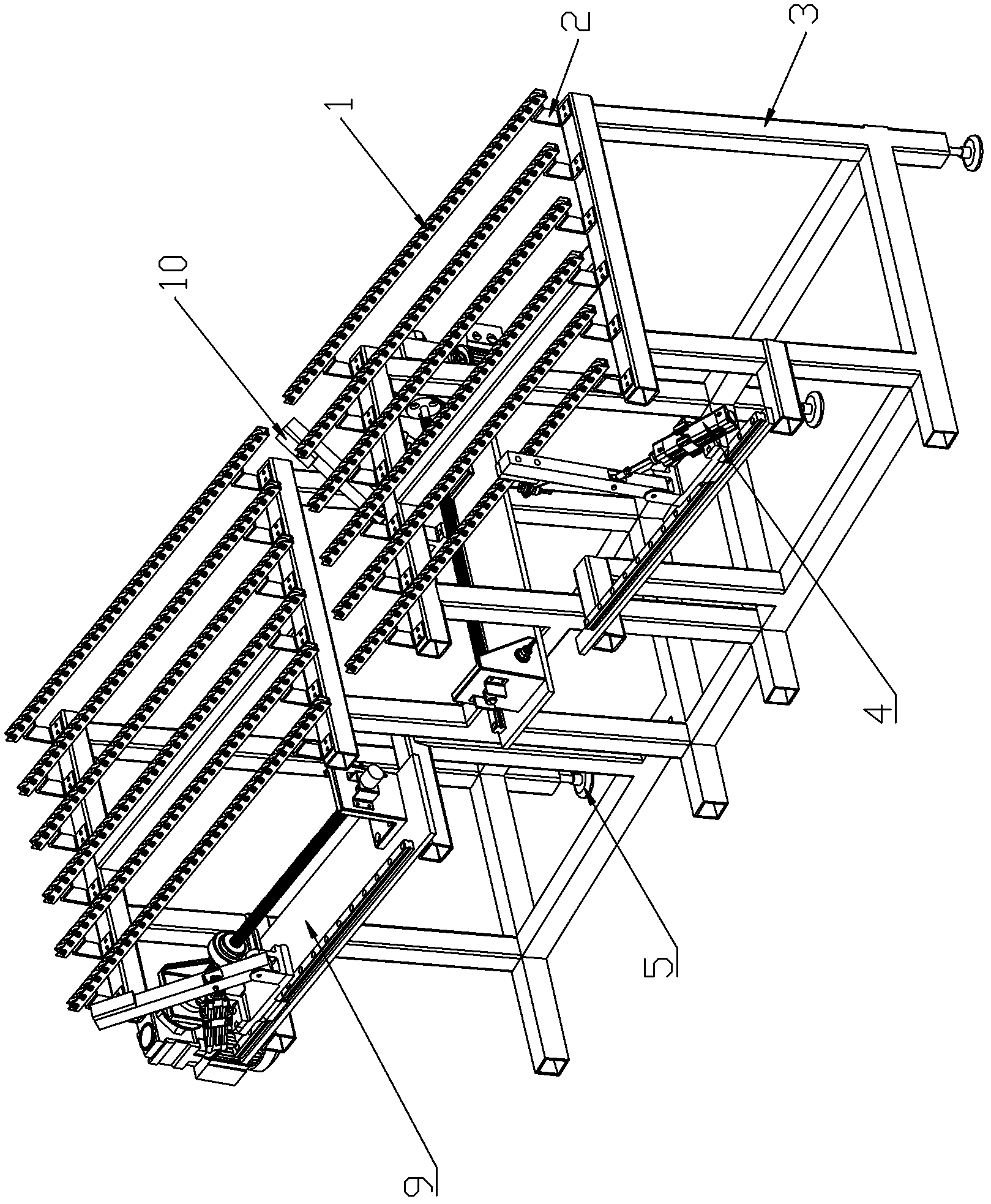

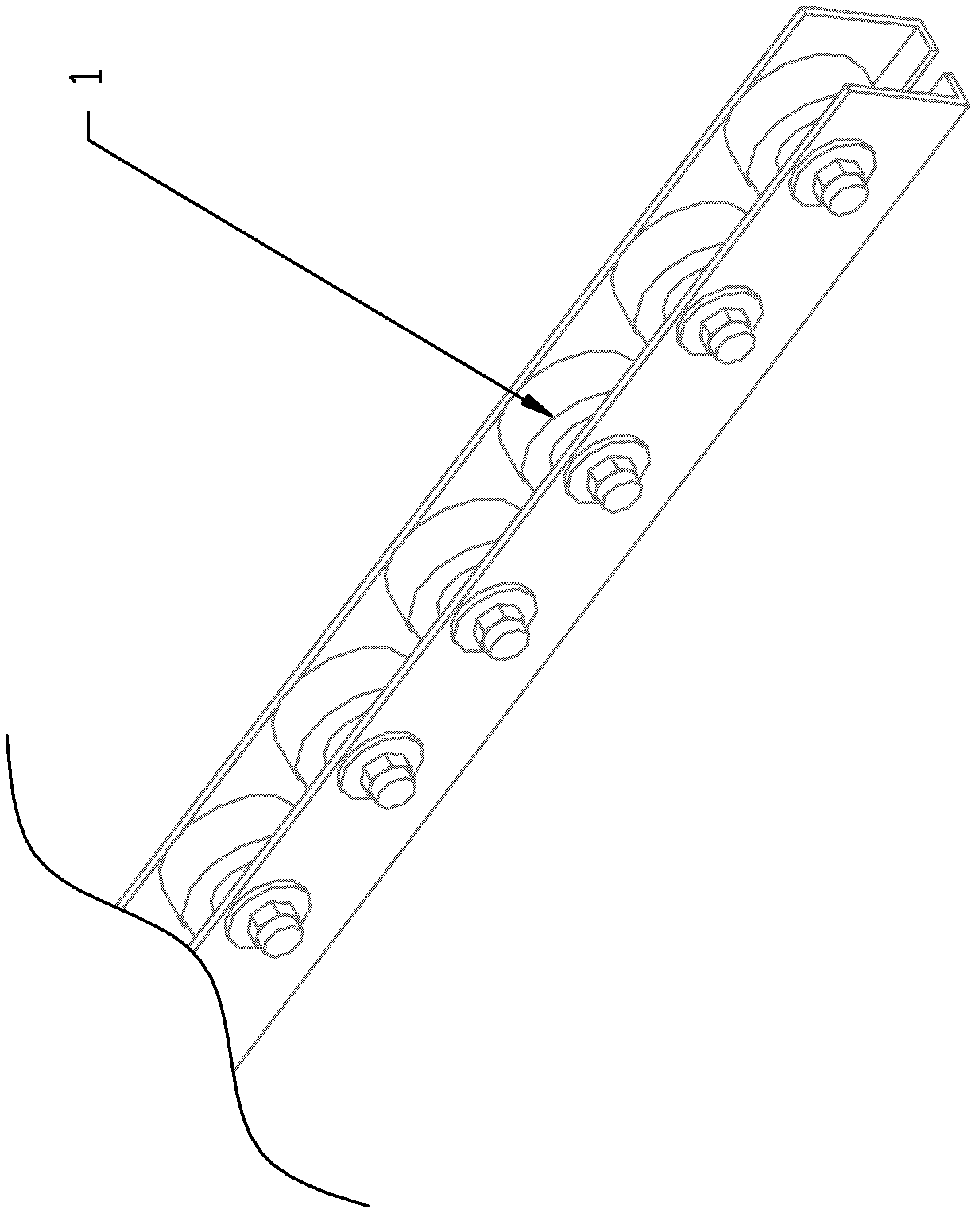

[0022] see figure 1 , the frame 3 used for the sheet metal positioning centering device of the stamping automation line is a cubic frame, and its top surface is slope-shaped, and two rows of roller bars 1 are evenly distributed through the U-shaped bracket 2 along the slope direction of the top of the frame. One row of roller bars is located on the top of the rack, and the other row of roller bars is located on the lower part of the rack top, forming a roller bar slope. The angle between the roller bar slope and the horizontal plane is 7 degrees. The distance between two rows of roller bars is 100mm; the gap between two adjacent roller bars 1 is 100mm; the roller bars include channel steel-shaped roller grooves, and rollers are evenly distributed in the roller grooves, and the rolling direction of the rollers is The direction of the slope at the top of the rack. Adjustment blocks 5 are installed at the bottom of each leg of the frame 3; rotating arm adjustment mechanisms are ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com