Multi-operating condition extreme load testing system and method for wheel loader transmission system

A wheel loader and load testing technology, which is applied in the direction of machine gear/transmission mechanism testing, etc., can solve the problems that it is difficult to simulate the working posture of the loader, does not include the maximum extreme load, and the test time is long, so that the test is convenient and labor-saving , Reduce test cost, save time and cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0046] The specific content and working process of the present invention will be further described below in conjunction with the embodiments shown in the accompanying drawings.

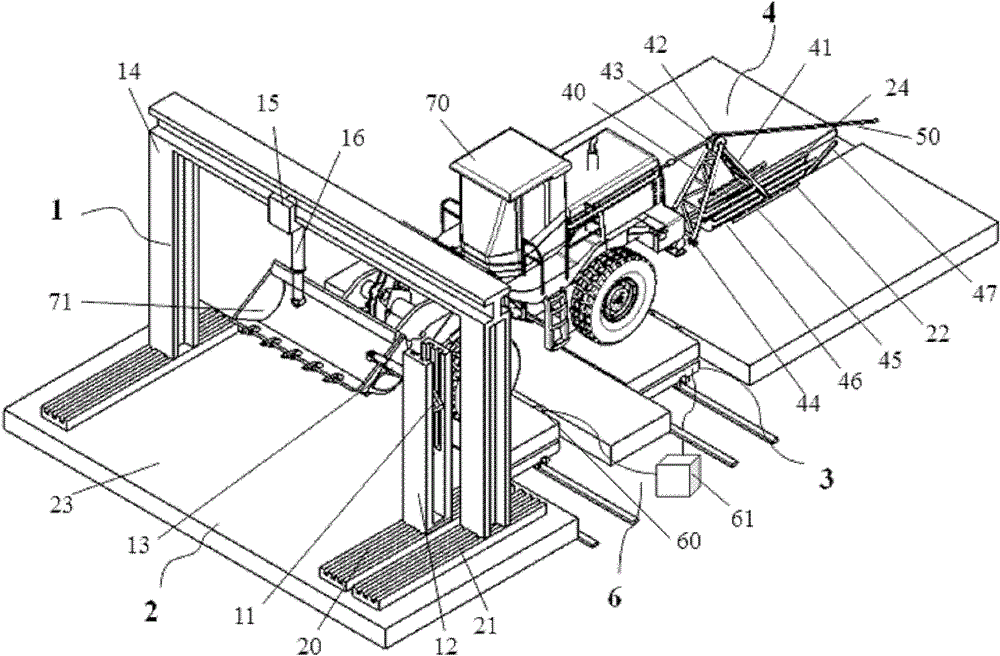

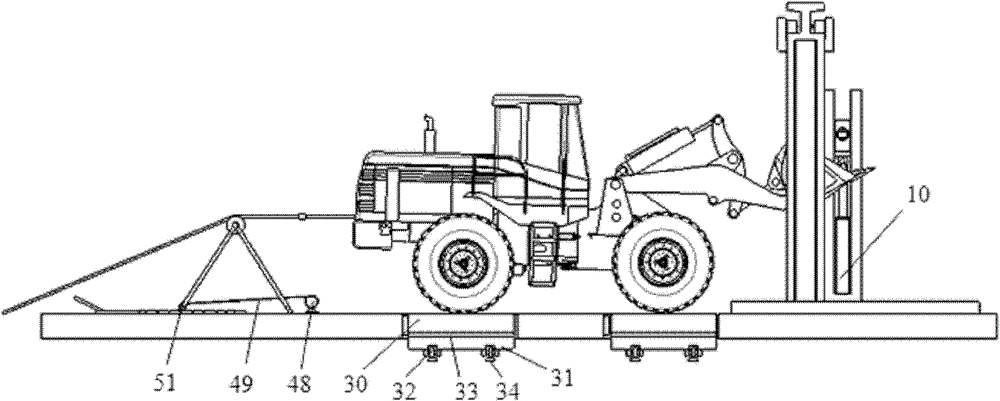

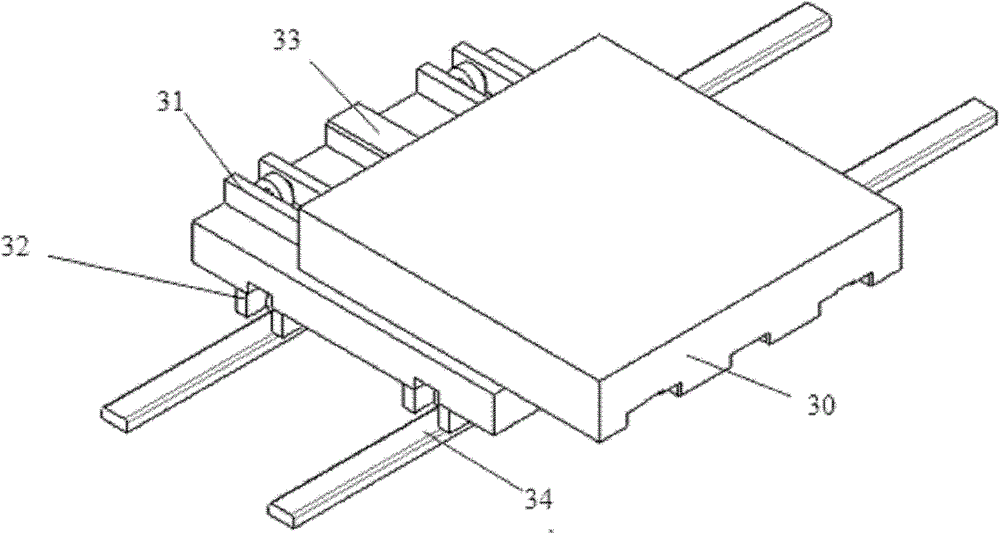

[0047] figure 1 It is the overall schematic diagram of the wheel loader drive train multi-condition extreme load test system, figure 2 It is a front view of the multi-working-condition extreme load test system for the wheel loader drive train. It can be seen from the figure that the multi-work-condition extreme load test system for the wheel loader drive train of the present invention is mainly composed of dynamic loading Module 1, supporting module 2, simulated road surface module 3, traction module 4 and data acquisition and recording module 6, power loading module 1, simulated road surface module 3, traction module 4 and data acquisition and recording module 6 are all fixed on the support module 2 Above, the power loading module 1 is located in front of the loader 70 to be tested, providing later...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com