Cover type annealing furnace

A bell-type annealing furnace and annealing technology, applied in furnaces, heat treatment furnaces, furnace types, etc., can solve the problems of uneven temperature in annealing furnaces, poor annealing effects, and low product quality, and achieve enhanced annealing effects, saving manpower, The effect of improving product quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

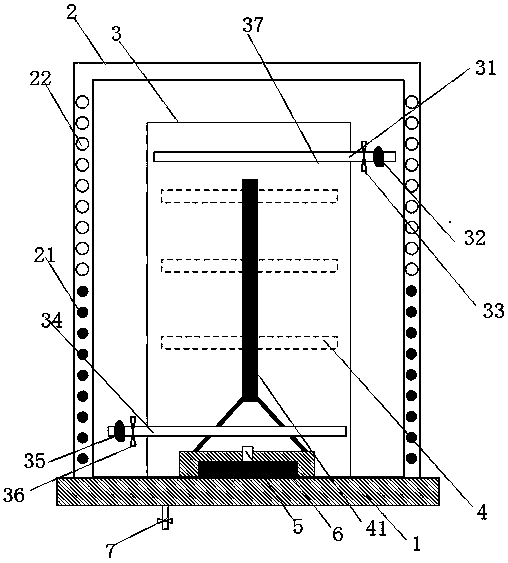

[0025] see figure 1 , a bell annealing furnace, comprising a furnace base 1, a heating and cooling cover 2, a protective cover 3, an annealing frame 4, a temperature sensor 5, a PLC programming controller 6;

[0026] The heating and cooling cover 2 and the protective cover 3 are installed on the furnace base 1; in order to further increase the air tightness in the furnace, a sealing ring can be provided at the connection between the heating and cooling cover 2, the protective cover 3 and the furnace base 1;

[0027] The heating and cooling cover 2 includes an inner interlayer, in which a heating element 21 and a cooling pipe 22 are arranged; while realizing the dual functions of heating and cooling, in order to further avoid mutual interference and make the heat distribution more uniform, the heating element 21 is arranged at the lower part of the inner interlayer, and the cooling pipe 22 is arranged at the upper part of the inner interlayer.

[0028] The protective cover 3 i...

Embodiment 2

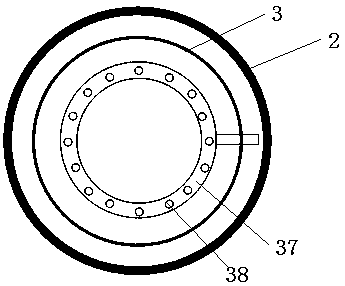

[0032] see figure 1 with figure 2 , the upper air guide port 31 and / or the lower air guide port 34 is provided with an inner extension pipe 37 , and the inner extension track extends to the inside of the protective cover 3 . Therefore, the heat exchange between the inside and outside of the protective cover 3 is faster and more uniform.

[0033] The inner extension pipe 37 can be circular, straight or quadrilateral.

[0034] Further, the inner extension pipe 37 is provided with several dispersion holes 38 . Adding dispersing holes 38 makes the heat evenly dispersed by the air flow, thereby further ensuring the uniformity of the temperature in the furnace.

[0035] The rest of the structures and advantages are exactly the same as in Embodiment 1.

Embodiment 3

[0037] see figure 1 , the bell annealing furnace is provided with a gas exchange port 7 with a valve. It is used to input and output gas according to the needs of annealing. The gas exchange port 7 is arranged at the bottom of the bell annealing furnace.

[0038] The rest of the structures and advantages are exactly the same as in Embodiment 1.

[0039] The present invention can also combine at least one of the technical features described in Embodiments 2 and 3 with Embodiment 1 to form a new implementation.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com