Elastic energy storage safety device for tank container

A safety device and container technology, applied in safety belts, life-saving equipment, etc., can solve problems such as poor safety and lack of safety devices, and achieve the effect of easy processing and use, low cost, and guaranteed safety

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment approach 1

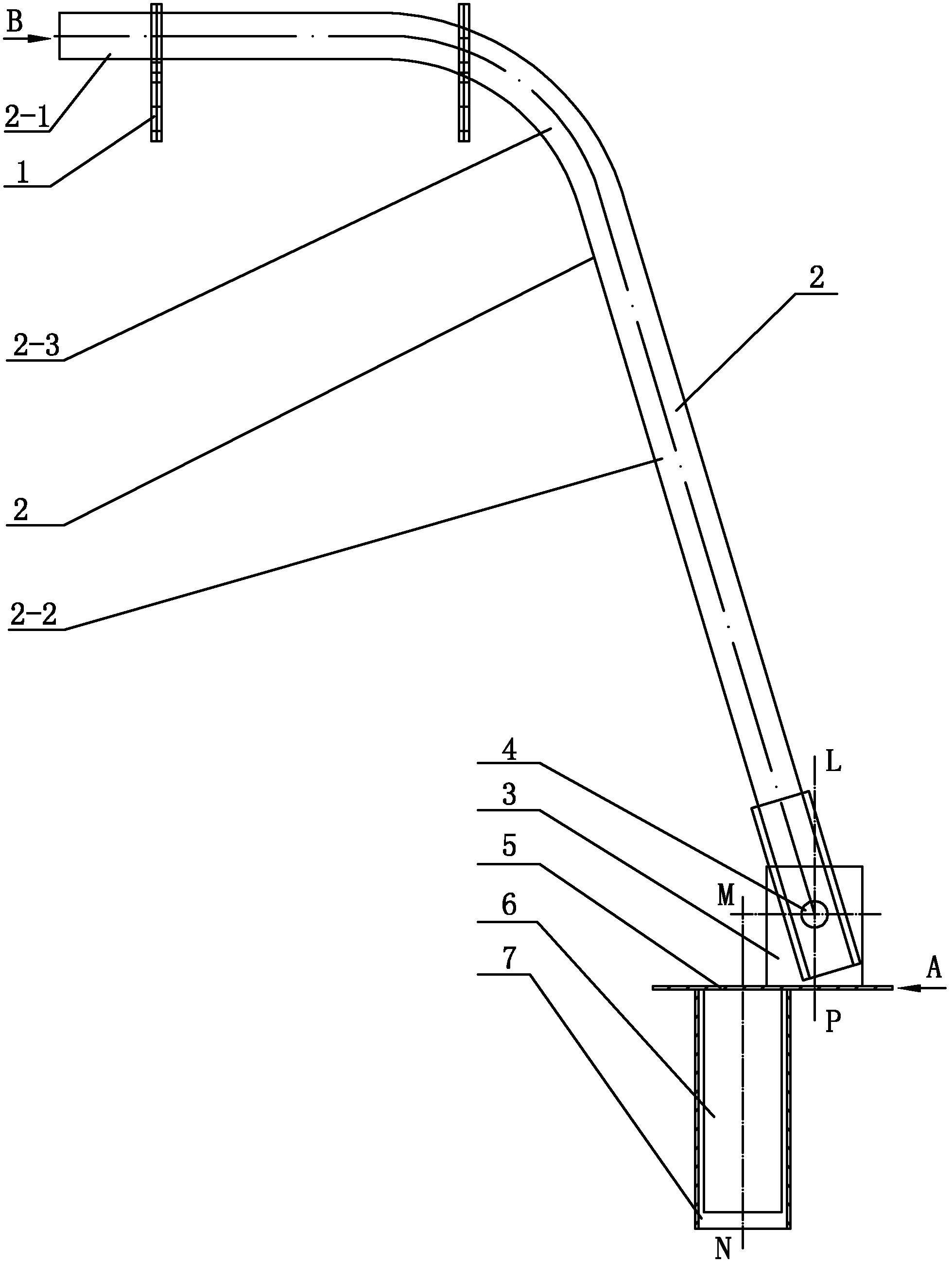

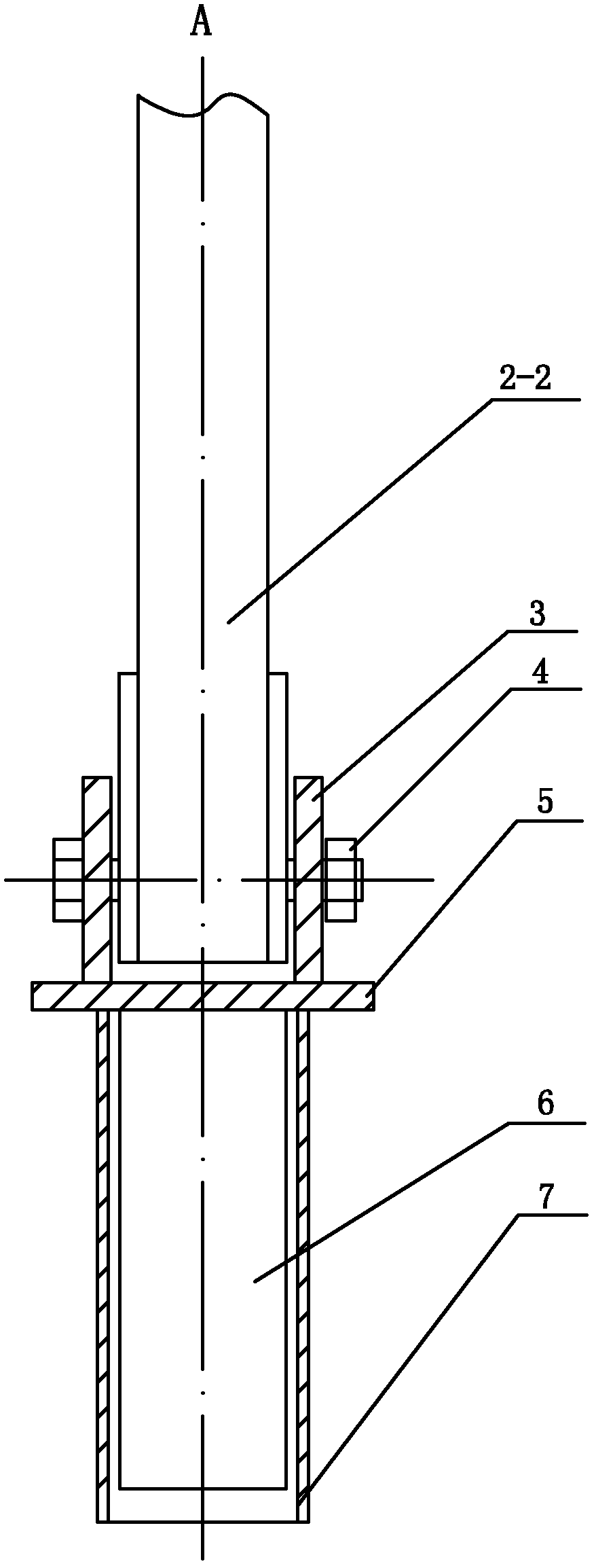

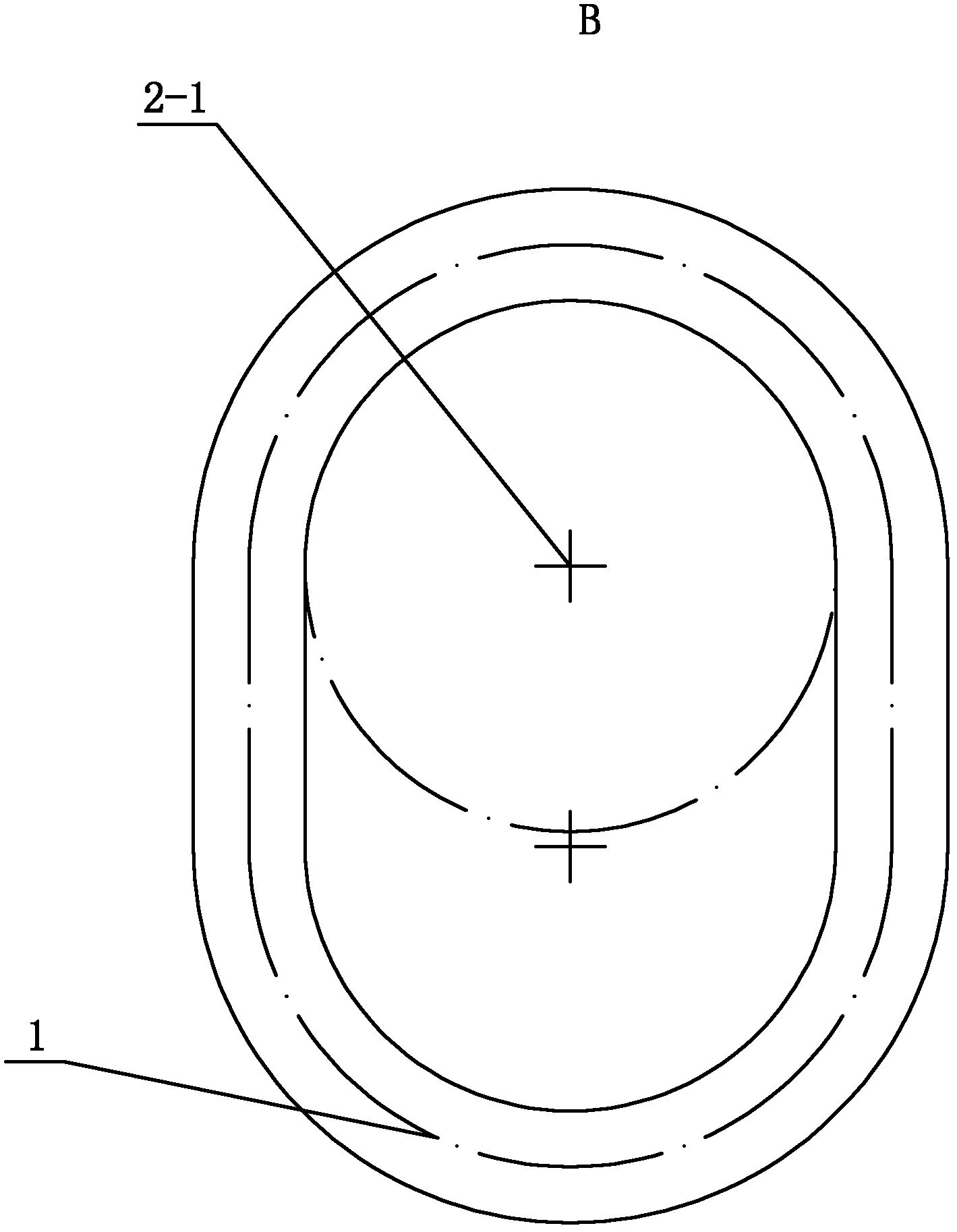

[0007] Specific implementation mode one: combine Figure 1 ~ Figure 3 Describe the present embodiment, the elastic energy storage safety device for the tank container described in the present embodiment includes a suspension ring 1, a connecting rod 2, a cover plate 5, a square pipe 6, a square pipe sleeve 7 and two clips 3, the The connecting rod 2 is an arched connecting rod, and the arched connecting rod is composed of a short rod 2-1, a long rod 2-2 and an arc rod 2-3, and the short rod 2-1 and the long rod 2-2 form Eight-shaped setting, the arc rod 2-3 is arranged between the short rod 2-1 and the long rod 2-2 and the three are made in one piece, the square pipe sleeve 7 is poured in the ground, and the lower end surface of the cover plate 5 is connected with Square pipe 6, square pipe 6 is installed in the square pipe sleeve 7, and two clips 3 are fixed on the upper end surface of cover plate 5 in parallel, and the short rod 2-1 of connecting rod 2 is connected with lift...

specific Embodiment approach 2

[0008] Specific implementation mode two: combination figure 1 To describe this embodiment, the central axis MN of the square pipe 6 in this embodiment is parallel to the straight line LP perpendicular to the center line between the two clips 3 . Set in this way, the central axis of the square tube 6 and the vertical line of the center line between the two clips 3 are not on the same line (not coincident), and the eccentric line can ensure that the square tube 6 and the square tube sleeve 7 do not fall off from the round hole , safe and reliable work. Others are the same as in the first embodiment.

specific Embodiment approach 3

[0009] Specific implementation mode three: combination figure 1 and figure 2 This embodiment is described, the long rod 2 - 2 of the connecting rod 2 of this embodiment is detachably connected to the two clips 3 by bolts 4 . Such setting ensures that the connecting rod 2 cannot move longitudinally, the connection is efficient, and the use is convenient. Others are the same as in the first embodiment.

[0010] work process

[0011] combine Figure 1 ~ Figure 4 To illustrate the working process, a round hole with a diameter of φ100 and a depth of 200 mm is drilled on the ground at a distance of 2500 mm from the center line of the rotating tire 8; the square pipe sleeve 7 is poured into the round hole and fixed, and the lower end surface of the cover plate 5 is fixedly connected to the square pipe 6 , the square pipe 6 is put into the square pipe sleeve 7, the upper part of the large-scale tank-type container body 9 is welded by the suspension ring 1 and the connecting rod 2...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com