Universal adjustable balance bracket

A technology for balancing brackets and supports, applied in metal processing, metal processing equipment, manufacturing tools, etc., can solve the problems of inconvenient adjustment of rotating torque, the inability of the balance bracket to quickly realize the assembly angle of electric screwdrivers, etc., and achieve wide versatility and convenient operation. , the effect of improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

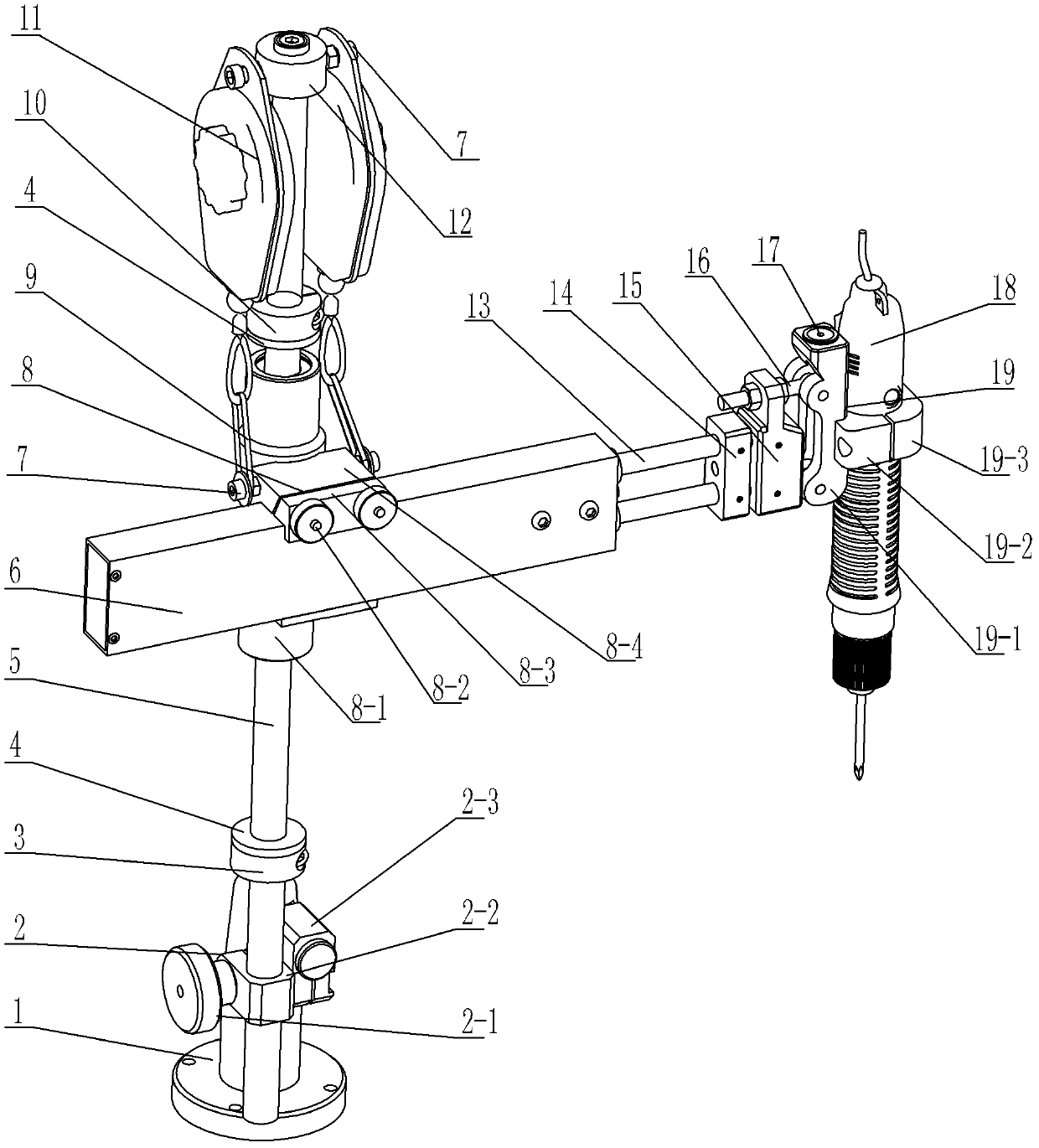

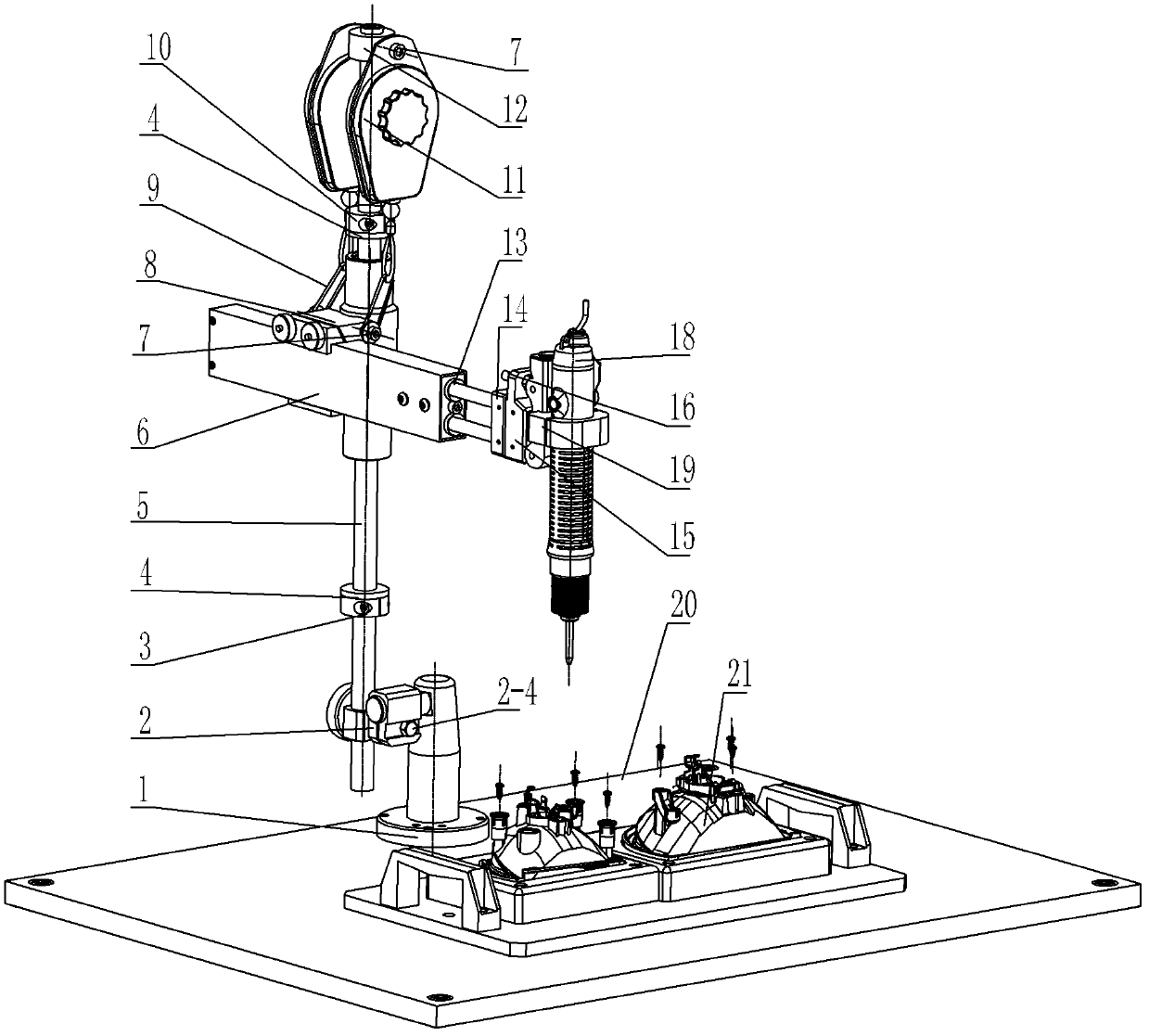

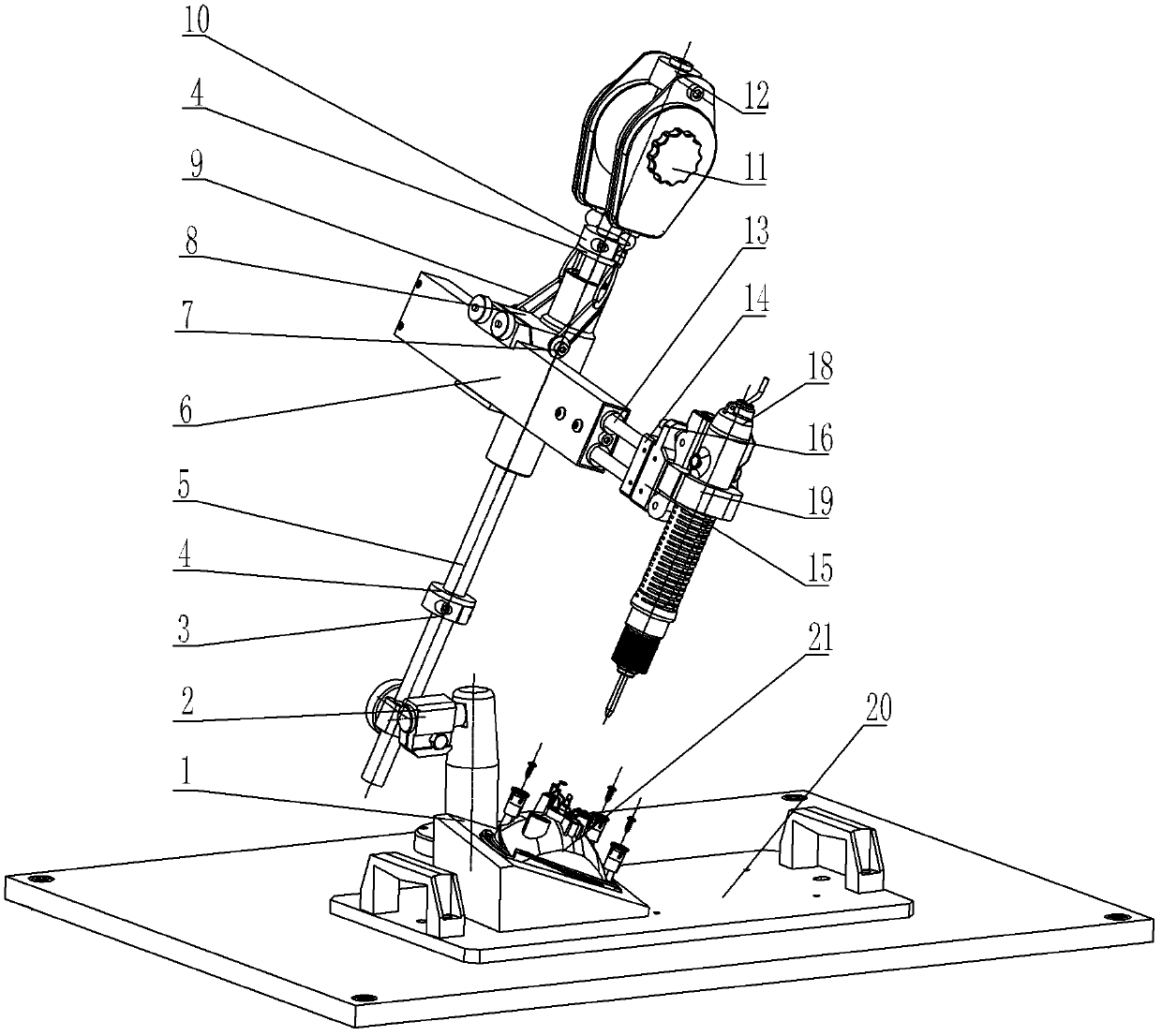

[0012] See Figure 1~3 As shown, the universally adjustable balance bracket of the present invention includes a bracket 5, a support 1, a bracket universal joint 2 installed on the support 1 and connected with the bracket 5 for adjusting the angle of the bracket 5, the support 1 The lower part has a flange, and the support 1 is installed on the workbench 20 through the flange on the support 1, and any angle of the support 5 can be adjusted through the support universal joint 2 to meet the required installation angle of the screw. See Figure 1~3 As shown, the bracket universal joint 2 of the present invention includes a fixed card seat 2-3, an adjusting card seat 2-2 and an adjusting bolt 2-4 and a nut 2-1, and has a mounting hole and a fixing card with a notch communicating with the mounting hole. The seat 2-3 is installed on the support 1, and the bolt is screwed on the support 1 through the installation hole of the fixed card seat 2-3, and the bracket universal joint 2 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com