Clamp type hoisting mechanism

A tong-type and tong-rod technology, which is applied in drilling equipment, earth-moving drilling, drill pipe, etc., can solve the problems of single function and high requirements on drilling tool structure, and achieve the effect of simple and reliable process, less mutual restriction, and convenient and simple maintenance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

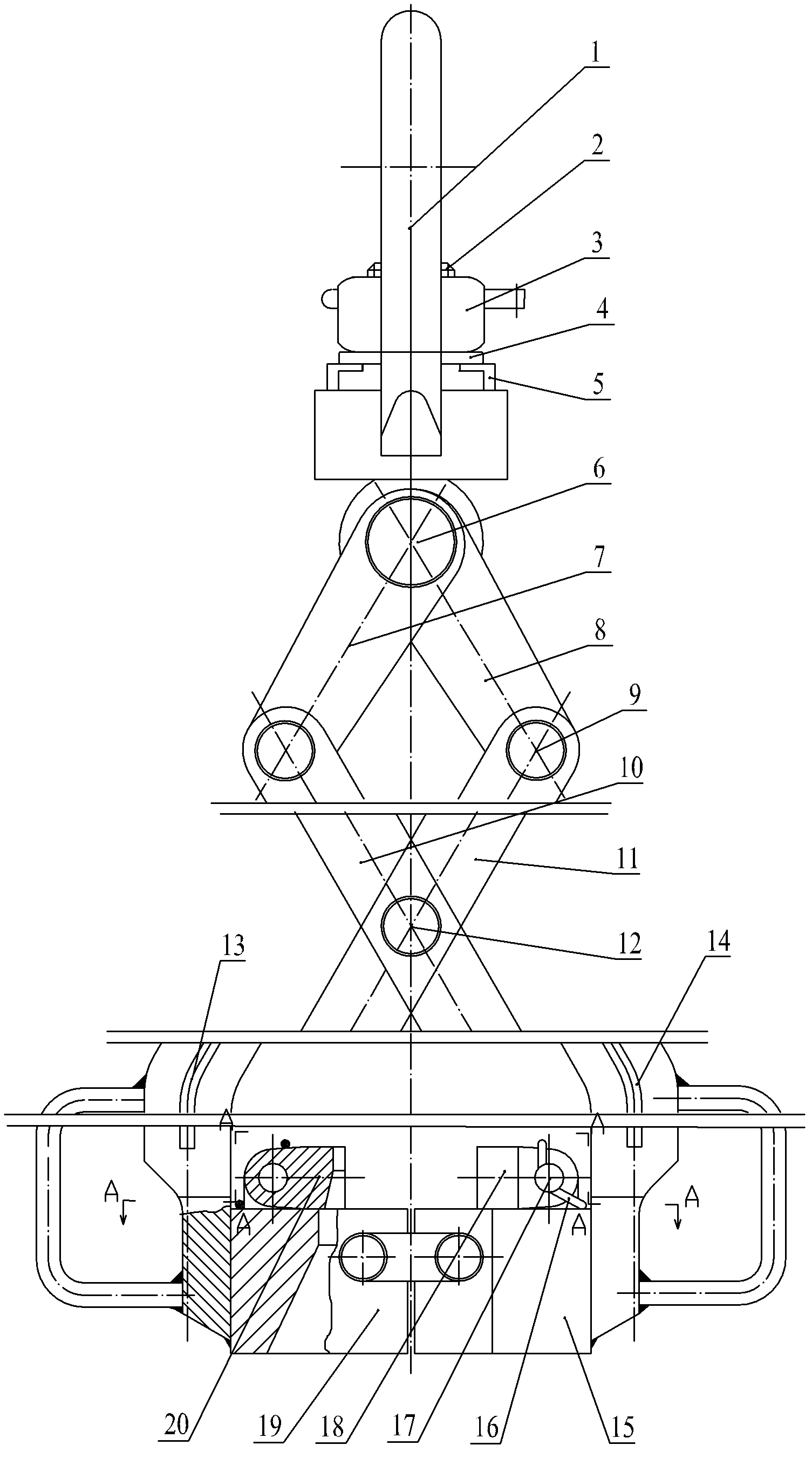

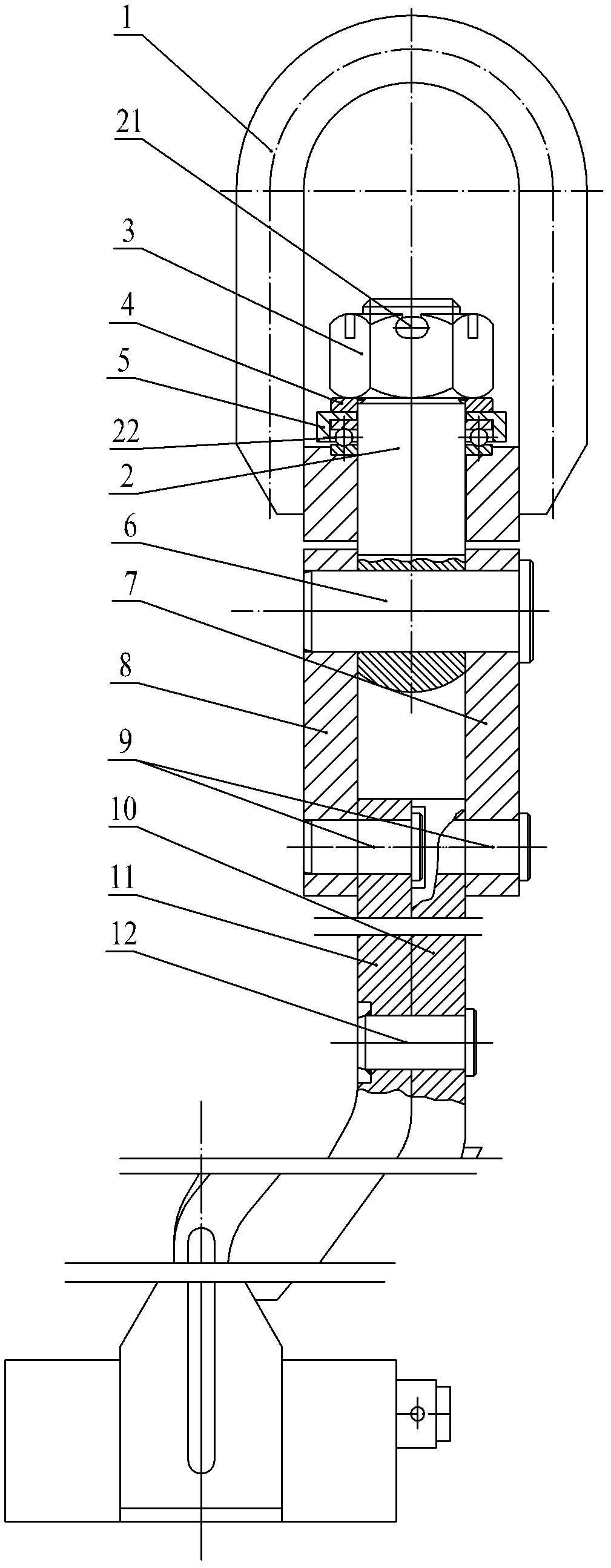

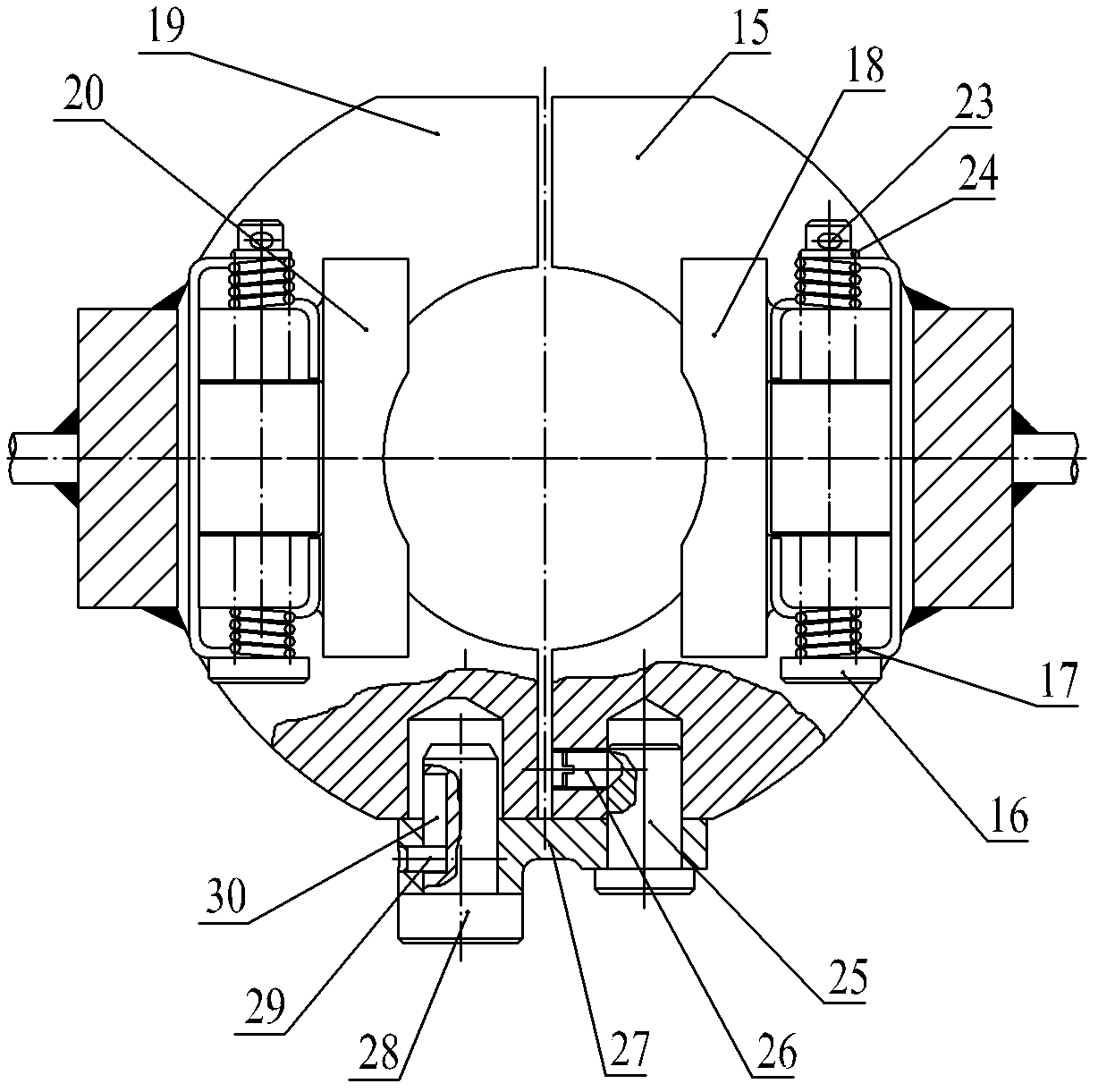

[0028] The present invention will be further described below in conjunction with specific drawings and embodiments.

[0029] As shown in the figure: the clamp-type lifting mechanism in the embodiment is mainly composed of lifting ring body 1, lifting shaft 2, hexagonal grooved nut 3, washer 4, dust cover 5, first pin shaft 6, left pull rod 7, right Pull rod 8, second pin shaft 9, left clamp rod 10, right clamp rod 11, third pin shaft 12, left connecting plate 13, right connecting plate 14, right seat body 15, torsion spring 16, shaft 17, right block 18. Left seat body 19, left block 20, cotter pin 21, one-way thrust ball bearing 22, cotter pin 23, washer 24, small shaft 25, set screw with tapered end 26, stopper 27, pull pin 28 and cylinder Parts such as pin 29 are formed.

[0030] Such as Figure 1~Figure 3 As shown, the lifting ring body 1 is provided with a shaft hole, and the lifting shaft 2 is installed in the shaft hole. The upper end of the lifting shaft 2 is fitted w...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com