Loading system and method for simulating soil pressure in test room

A loading system and earth pressure technology, applied in the direction of applying stable tension/pressure to test the strength of materials, can solve the problems of earth pressure and simulated loading of large-scale rock-soil media that have not been seen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

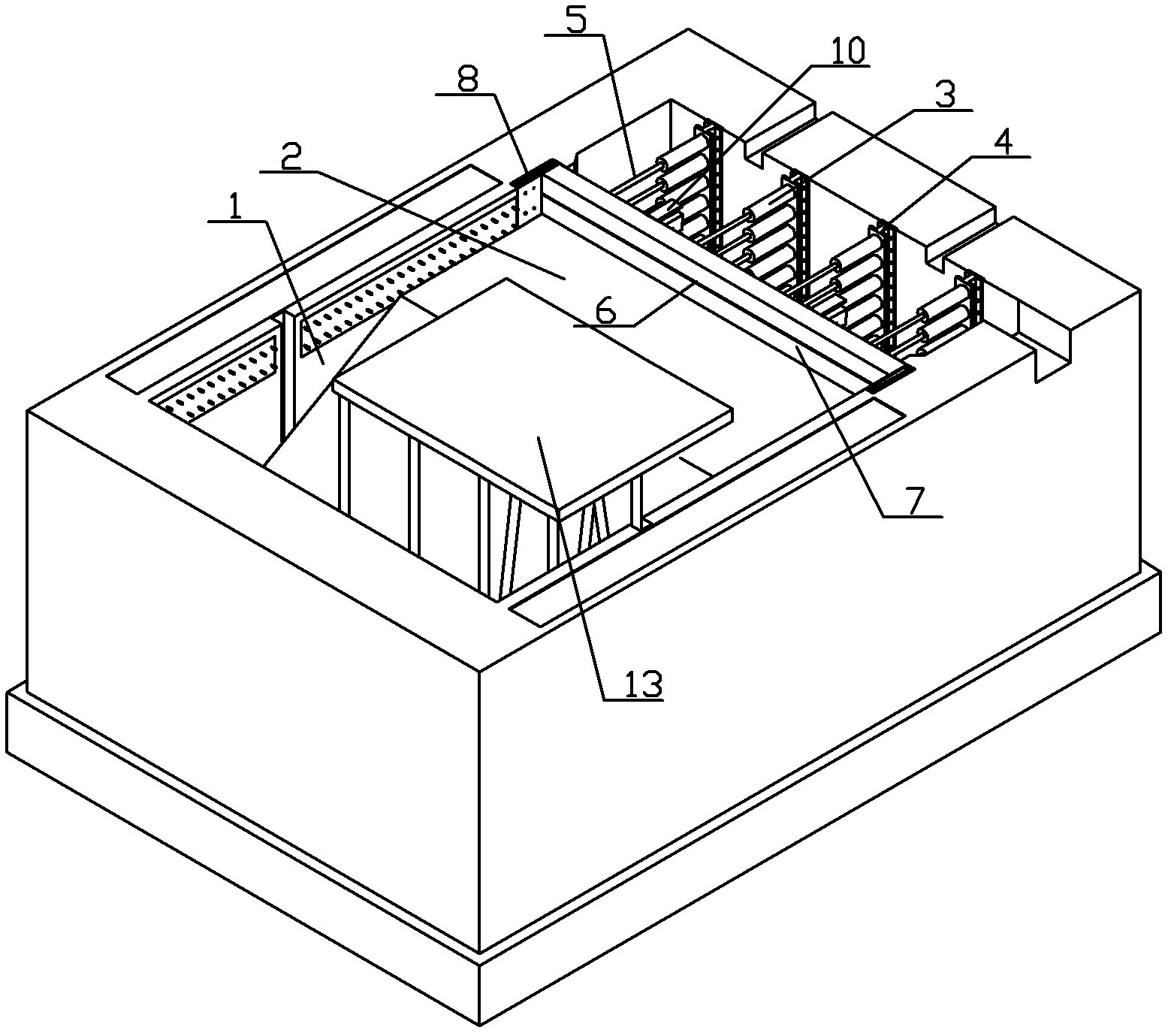

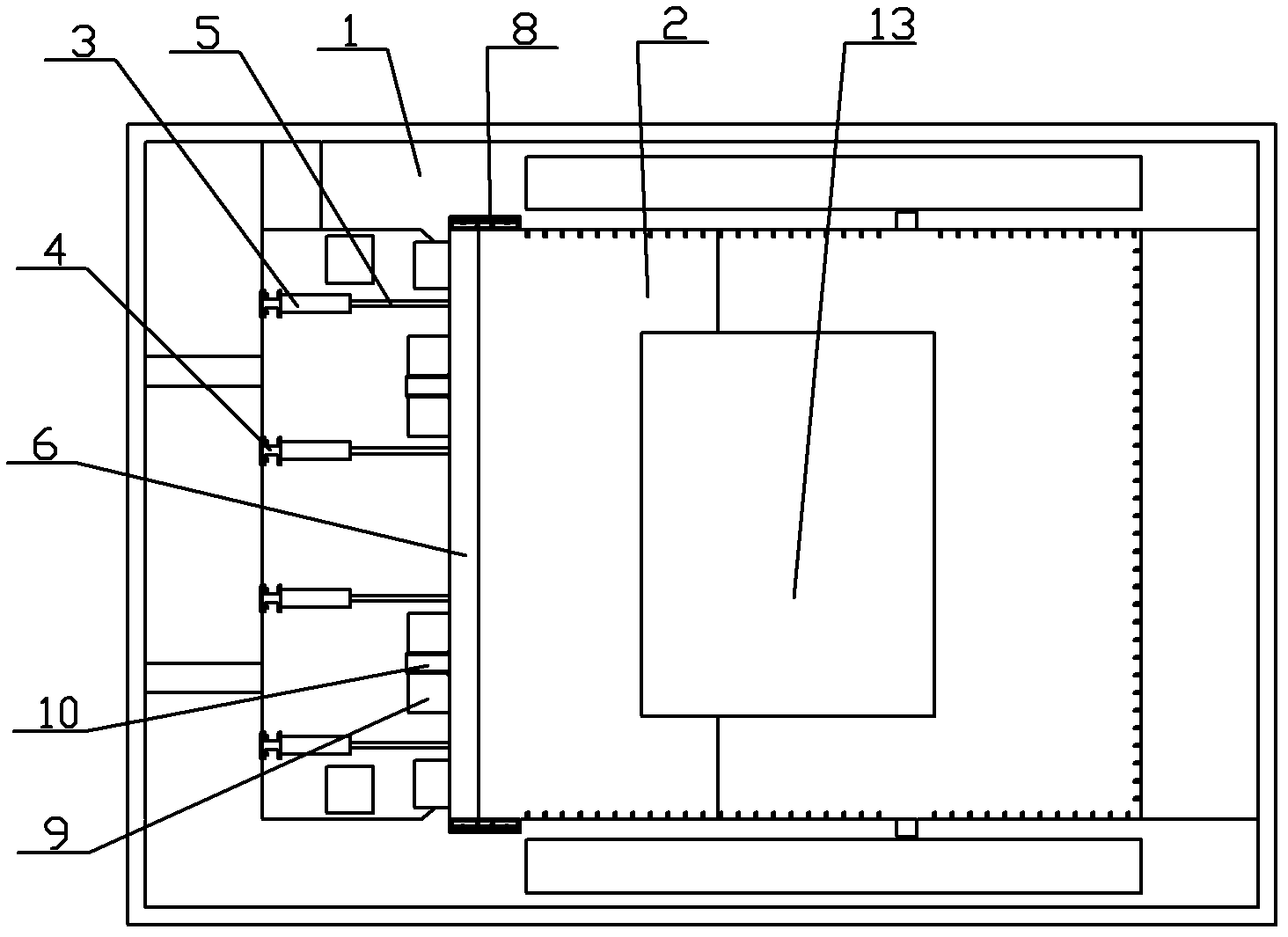

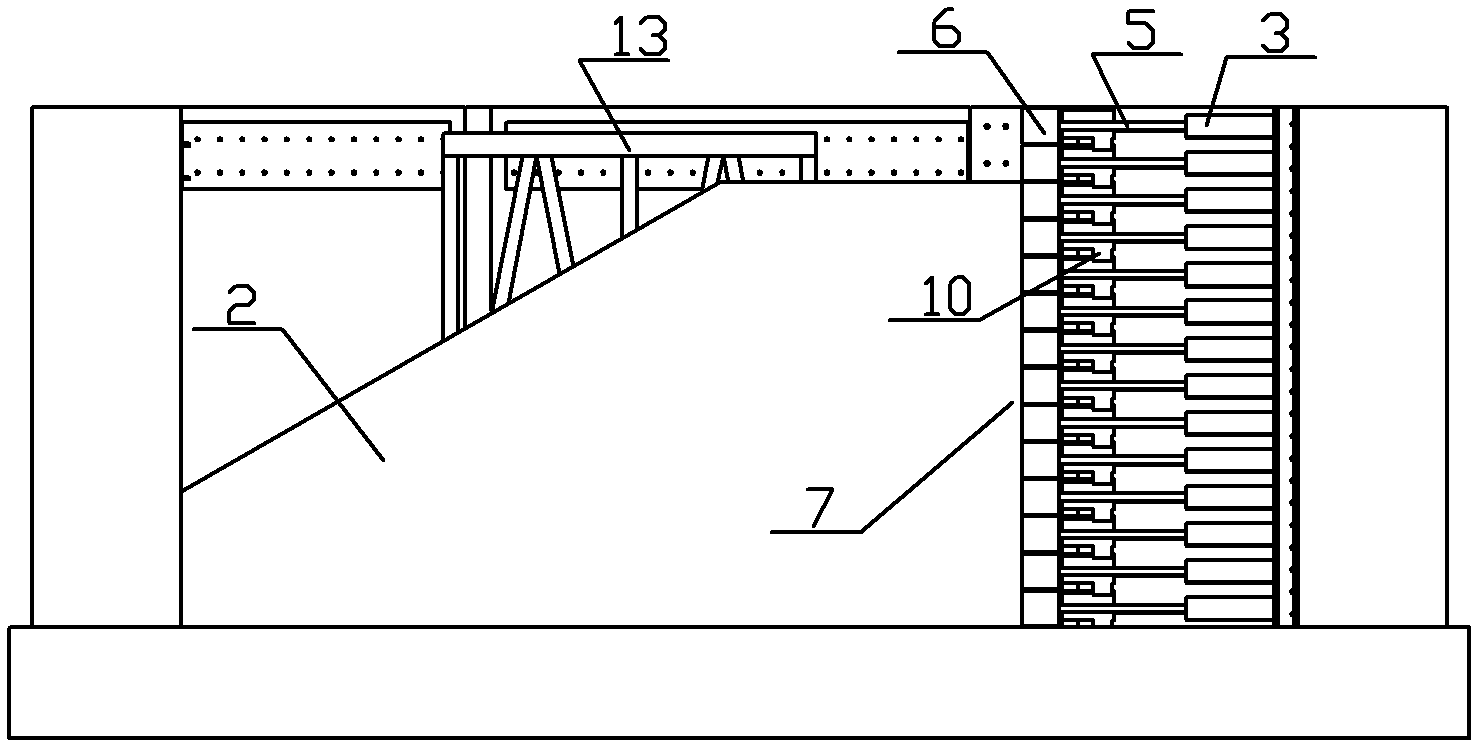

[0029] Such as figure 1 , figure 2 , image 3 and Figure 4 The loading system for simulating earth pressure in the test room shown is installed in a rectangular test pit 1 with a length of 15m, a width of 10m and a depth of 7m. The test soil 2 is arranged in the rectangular test pit 1. The loading system includes loading The actuator 3 is used to apply the load, and one end of the loading actuator 3 is installed on the actuator installation base 4, and the actuator installation base 4 is installed on the short side wall of the rectangular test pit 1, and the loading actuator 3 Multi-layer distribution along the vertical direction is used to simulate the soil pressure distribution of each soil layer in the test soil. Each layer of loading actuators is distributed evenly along the horizontal direction, and the other end of the loading actuator 3 passes through the dowel rod 5 is connected to the rear side of the horizontal loading beam 6 that can move back and forth, and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com