Method and system for measuring air flow pressure in test room

A test workshop, pressure technology, applied in the measurement of fluid pressure, measurement device, engine testing, etc., can solve problems such as airflow pressure fluctuations, and achieve the effects of no periodic fluctuations, good repeatability, and stable measurement data.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to better illustrate the technical solution of the present invention, the present invention will be further described through examples below.

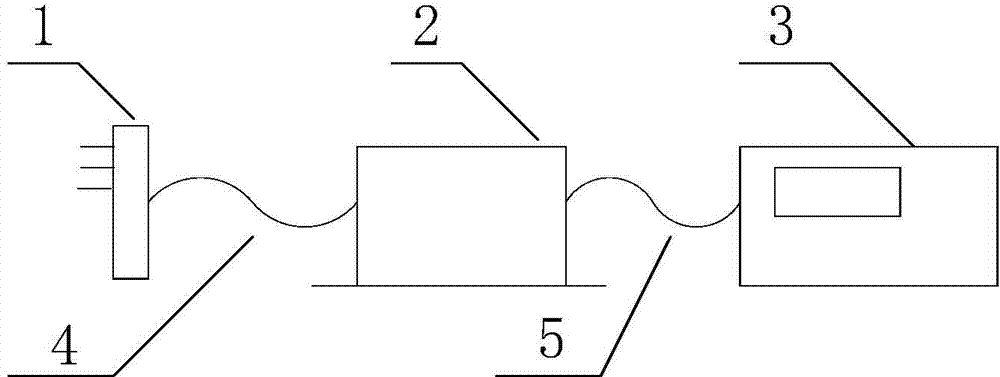

[0022] A method and system for measuring air pressure in a test workshop proposed by the present invention, comprising a pressure probe 1, a pressure scanning valve 2, a pressure controller 3, a first pressure induction pipe 4 and a second pressure induction pipe 5;

[0023] The method of measuring the airflow pressure in the test room and the steps of using the system are as follows:

[0024] Step 1: Fix the pressure probe 1 at the position to be tested in the test workshop, and use the pressure probe 1 to obtain the airflow pressure.

[0025] Step 2: Use the first pressure introduction tube 4 to introduce the gas flow pressure obtained by the pressure probe 1 into the measuring end of the pressure scanning valve 2 .

[0026] Step 3: Connect the reference end of the pressure scanning valve 2 with the output end of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com