A balanced production scheduling method based on multi-product and multi-line production mode

A production mode and production line technology, applied in the field of enterprise production scheduling, can solve the problems of increasing the planning workload and work difficulty, not fundamentally solving the problems of manual preparation of the master production plan for balanced production, and the inability to fully guarantee the rationality of the plan. To achieve the effect of good application prospects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

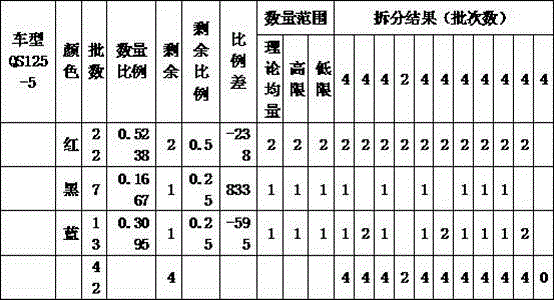

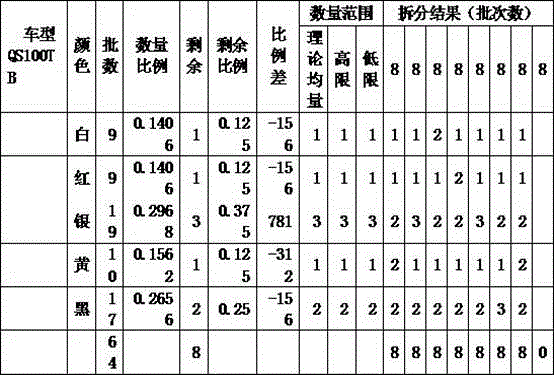

[0031] Take the production scheduling process of a motorcycle manufacturer's product assembly workshop as an example.

[0032] 1) Set up product group management

[0033] a) Various products that are not allowed to be produced continuously can be defined as a product group. Continuous production is not allowed between each product in a product group, there must be intervals between products of other product groups. ;

[0034] b) allow a product to belong to multiple product groups;

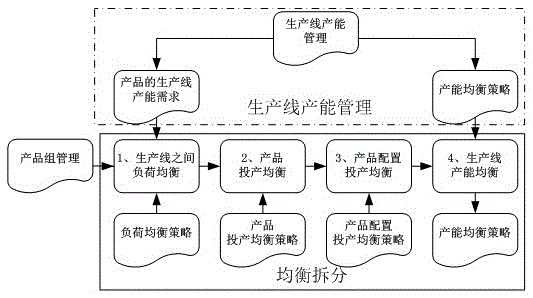

[0035] 2) Set up production line capacity management.

[0036] Maintain production line production capacity according to production lines and products, realize precise management of production line production capacity, adopt reasonable and economical batches, and use it to meet limited capacity scheduling requirements under the principle of equilibrium, in line with production balance, operation standardization, and production synchronization. in principle;

[0037] The balance strategy of pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com