Thread protector with flat-top back cover

A protector and back cover technology, which is applied in the directions of closing, packaging, transportation and packaging, can solve the problems of steel pipe corrosion, unsatisfactory protection of steel pipe end threads, and the protector is easy to enter water, etc., to avoid corrosion damage and achieve good sealing effect. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

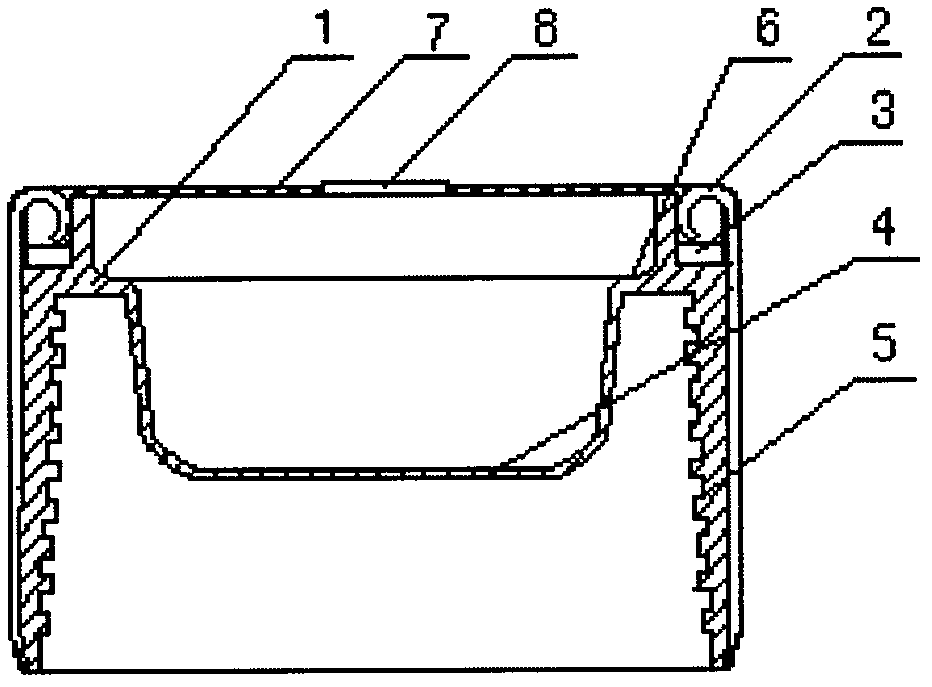

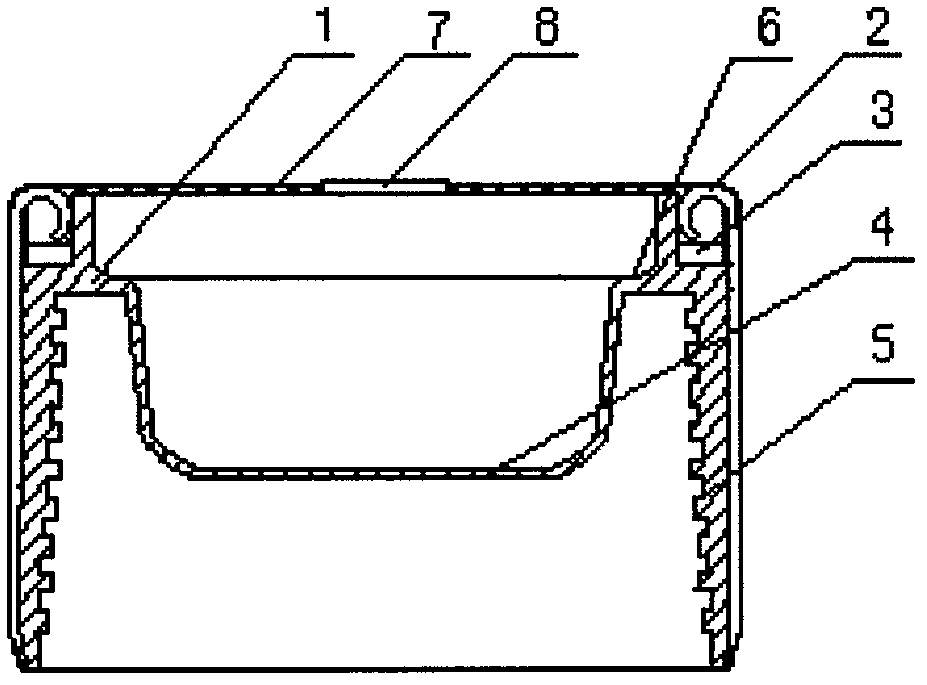

[0011] attached by figure 1 It can be seen that the present invention includes the steel sleeve 2 and the plastic inner lining 1 provided outside the steel sleeve 2, the top of the steel sleeve 2 is provided with an inwardly stretched arc, and a shoulder 3 is provided between the arc and the plastic inner liner 1. The upper part of the plastic lining 1 is provided with a cap 7, and the bottom of the cap 7 is provided with an inwardly recessed back cover 4. The depth of the back cover 4 should be greater than 1 / 2 of the overall height of the protective cover. The bottom cover 4 and the steel cover 2 A transition platform 6 is provided near the shoulders 3 between the tops. The inside of the plastic lining 1 and the outer wall of the steel sleeve 2 are provided with threaded threads 5, which are used to cooperate and connect with the protected steel pipe. The middle part of the above-mentioned capping 7 is provided with a dismounting hole 8 for installing and dismounting the pr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com