Tripod head

A technology of tripod head and body, which is applied in the field of hydraulic damping devices and damping devices, and can solve the problems that it is impossible to set zero damping force, the damping elements cannot be completely separated from each other, and the structure is complicated.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

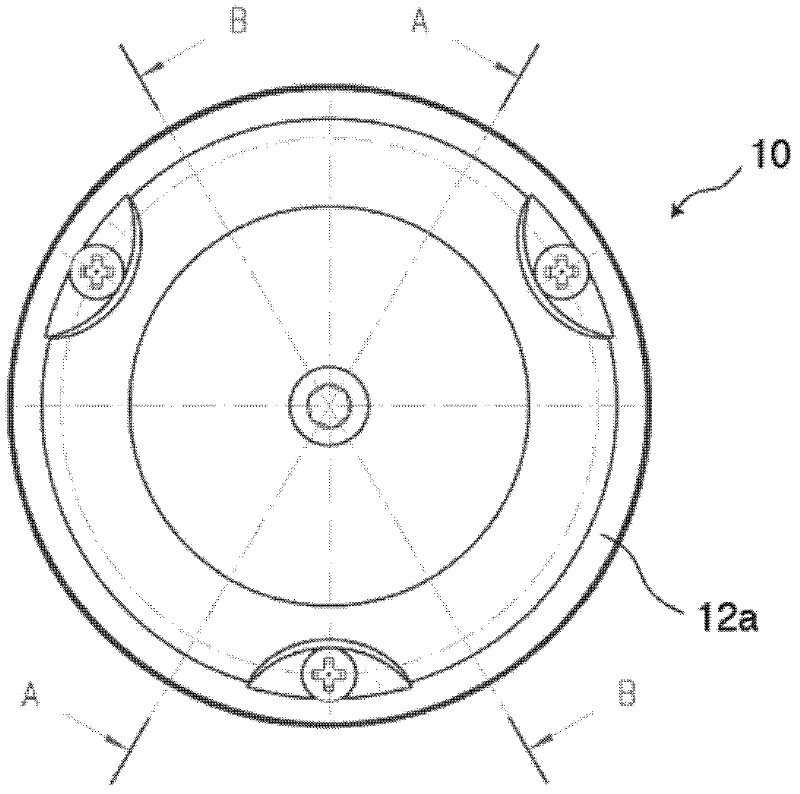

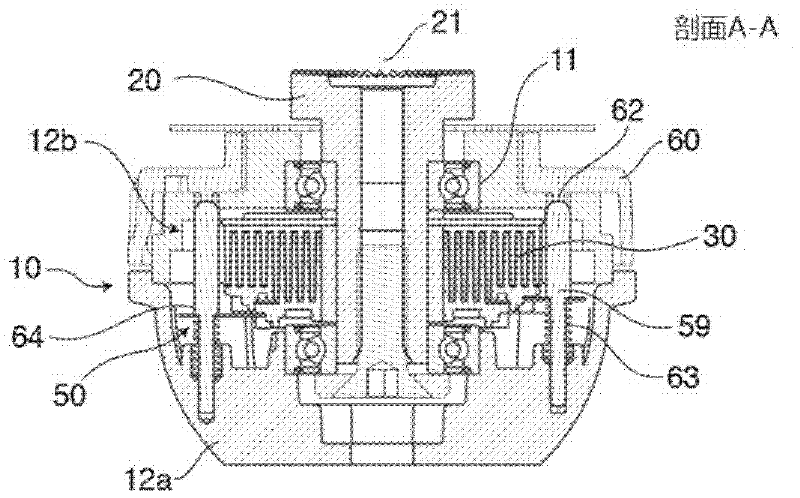

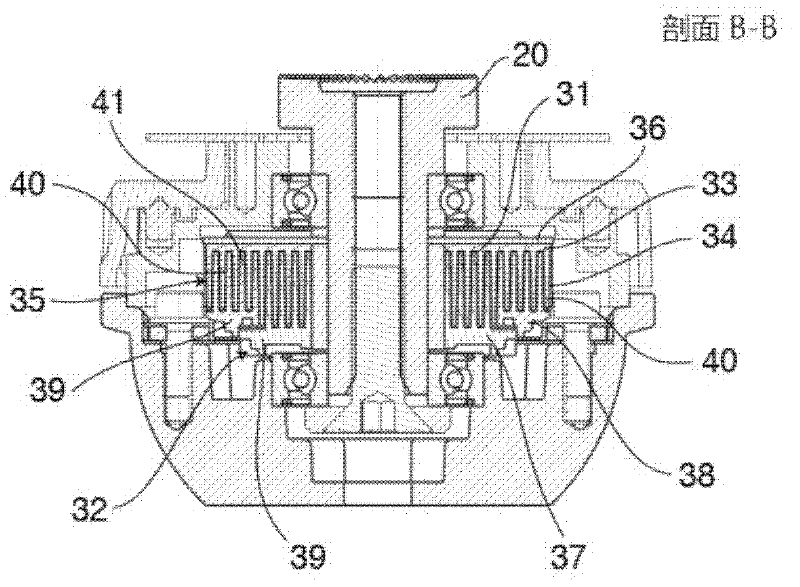

[0025] figure 1 A partial top view of the tripod head of the present invention is given. figure 2 and image 3Shown in is the base body 10 (second body), the shaft 20 (first body) is rotatably installed in the base body 10 through the bearing 11, and is connected with the intermediate body of the tripod head not shown in the figure. The shaft 20 is rotatable about a pivot 21 relative to the base body 10, which is usually fixed on a tripod. The base body 10 in the illustrated embodiment comprises two half shells 12a, 12b.

[0026] In order to be able to damp the rotational movement of the shaft 20 relative to the base body 10 , a damping device 30 is provided. The damping device mainly includes a first damping element 31 and a second damping element 32 .

[0027] The first damping element 31 has an annular chassis 33 coaxial with the pivot 21 . Several concentrically arranged annular ribs 34 extend from the chassis 33 along the axis (along the direction of the pivot 21 )....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com