Method for measuring tooth profile deviation of gear based on double-side meshing

A deviation measurement, gear tooth technology, applied in mechanical counter/curvature measurement, etc., can solve the problems of not being able to measure the left and right tooth surfaces at the same time, the inertia of the gear is large, and the measurement efficiency is low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

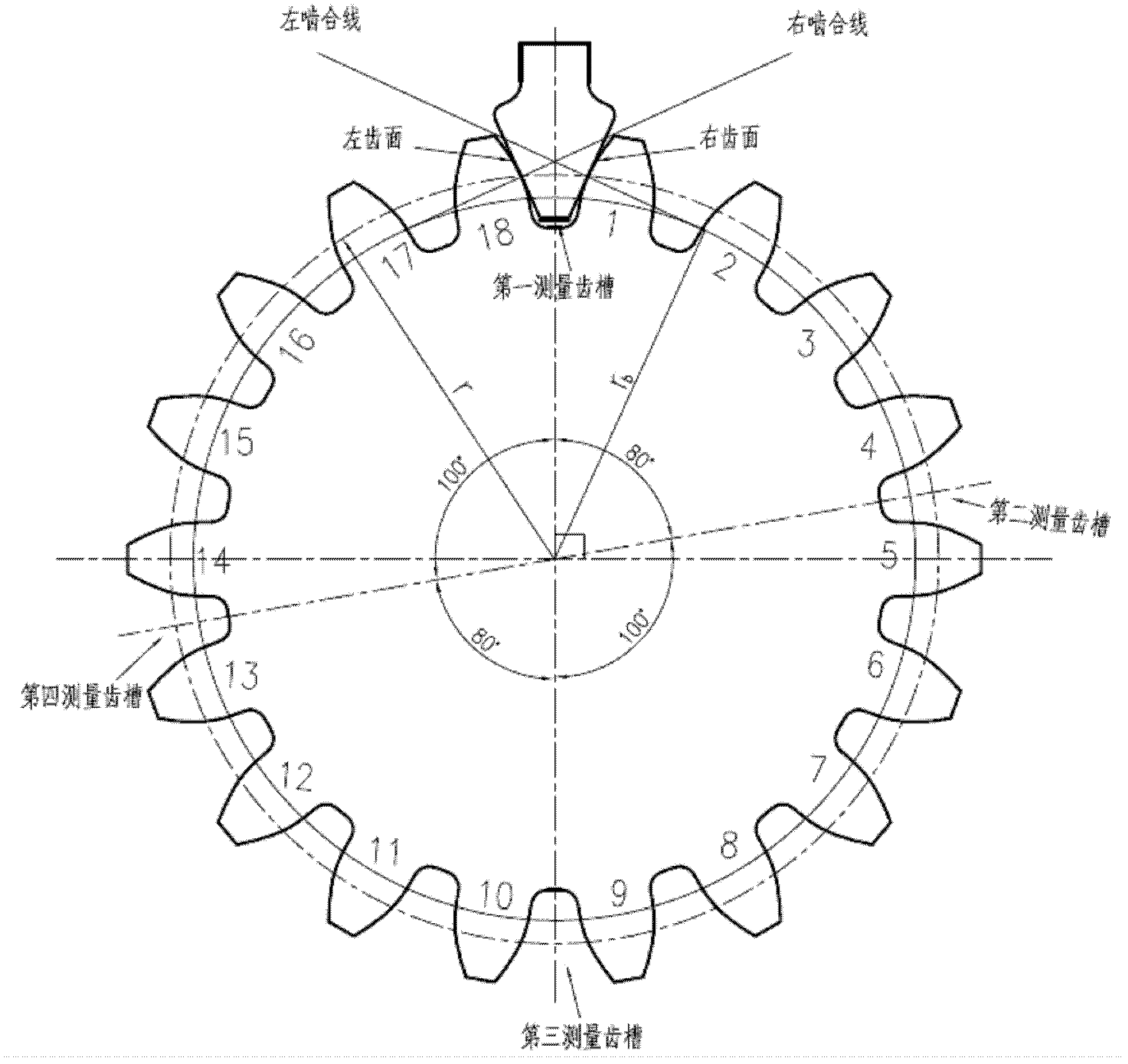

[0056] 1 This implementation takes a specific gear z=18 as an example to further explain the content of the invention:

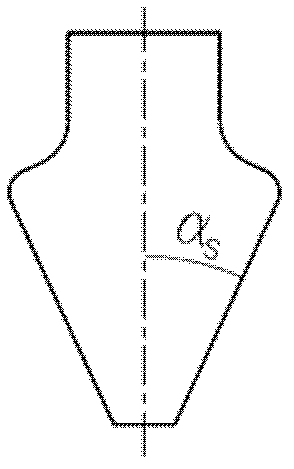

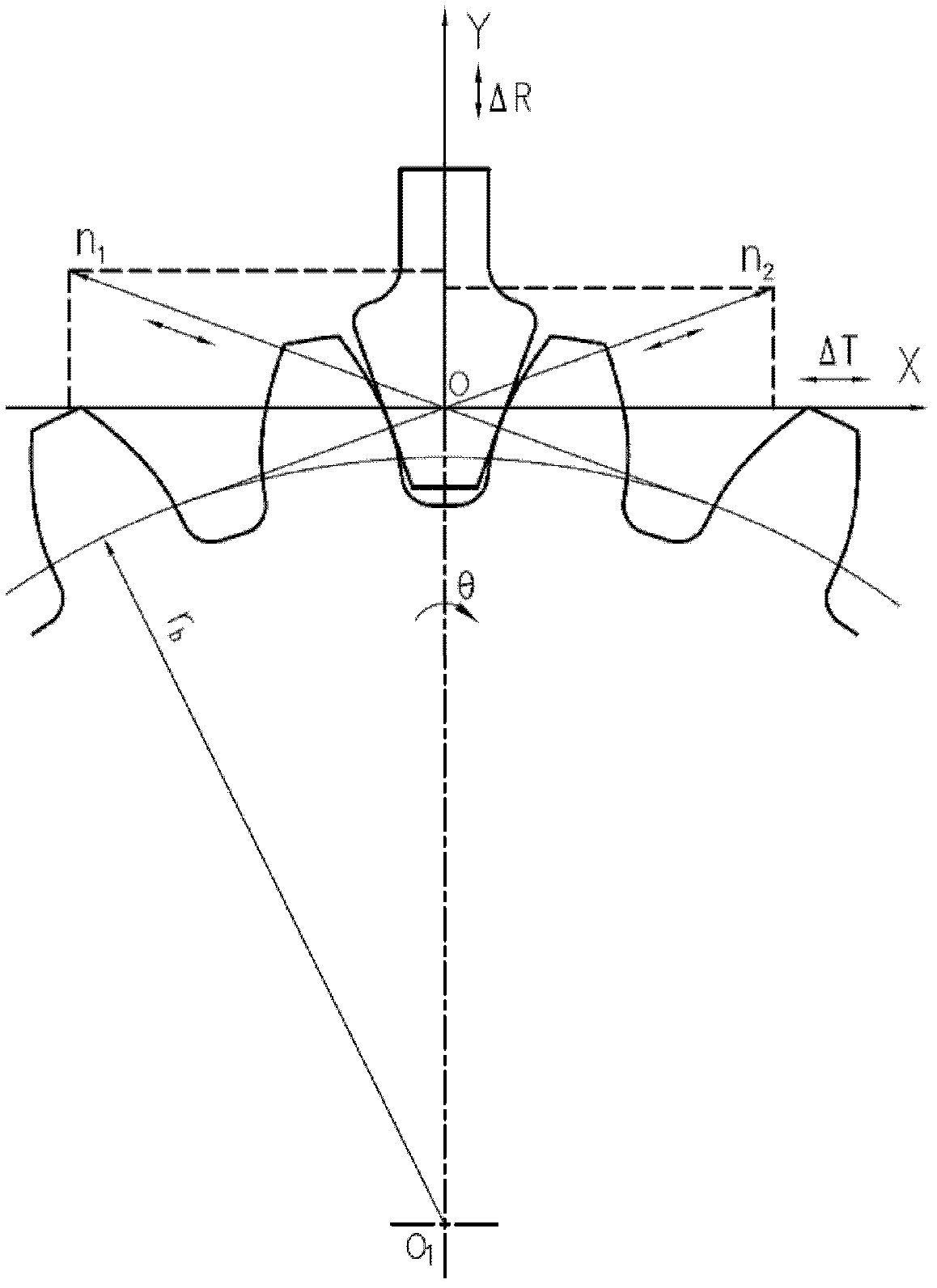

[0057] 1) The basic parameters of the known gear to be tested are as follows: z=18, m=2, α=20°; the basic parameters of the paired gear of the tested gear are as follows: z 1 =24, m=m 1 = 2, α = 20°;

[0058] According to the basic knowledge of gears, it can be concluded that:

[0059] Measured gear index circle radius: r = 1 2 mz = 18 mm

[0060] Radius of the base circle of the gear under test: r b =rcosα=16.9145mm

[0061] Radius of tooth tip circle of tested gear: r a = r + h a * m = ( 18 + 1 × 2 ) mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com