Method for measuring tooth profile deviation of gear based on double-side meshing

A technology of deviation measurement and gear teeth, which is applied in the direction of mechanical counter/curvature measurement, etc., can solve the problems of difficult selection of measurement reference, large inertia of gears, and low measurement efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

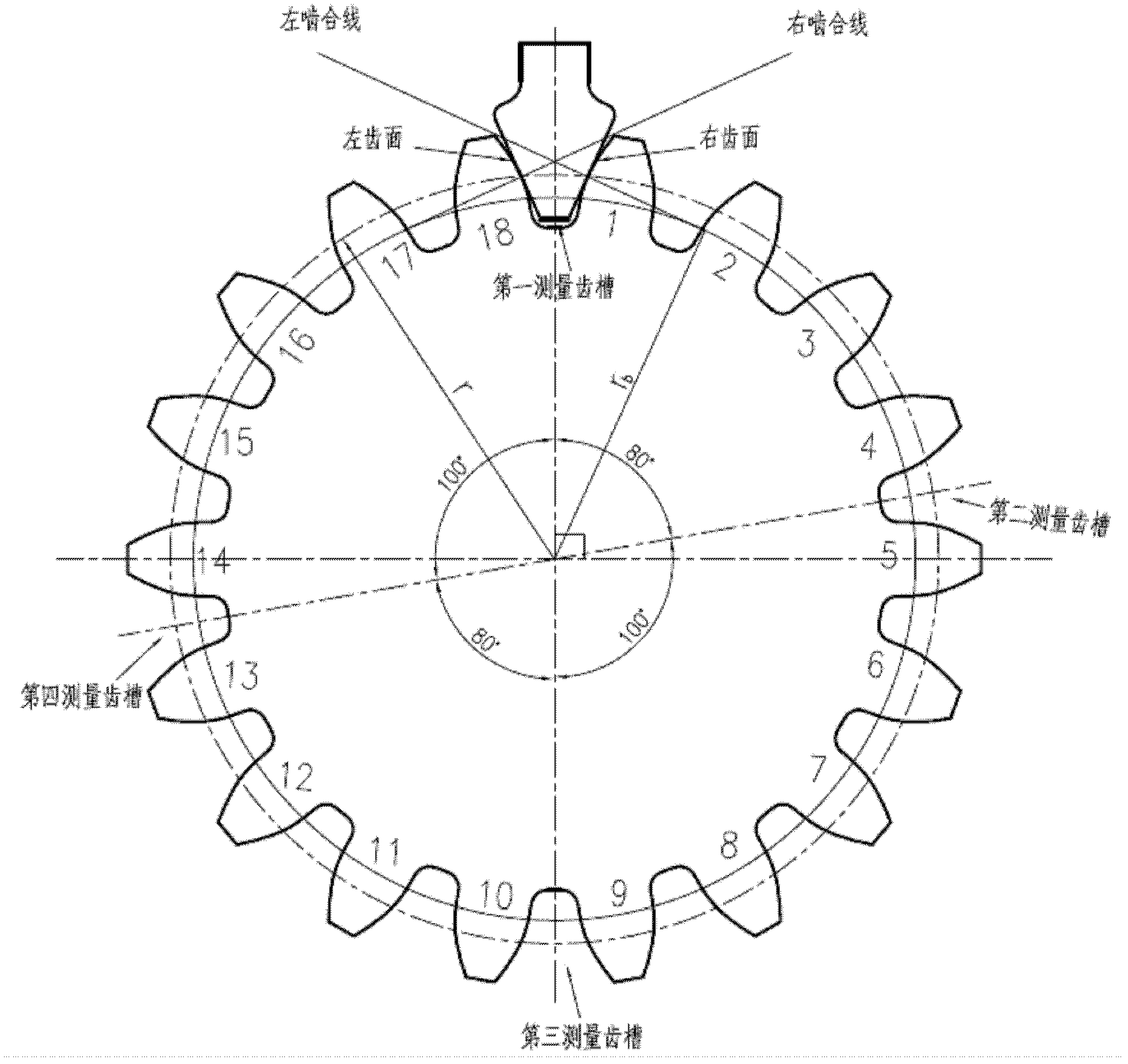

[0056] 1 This implementation takes a specific gear z=18 as an example to further explain the content of the invention:

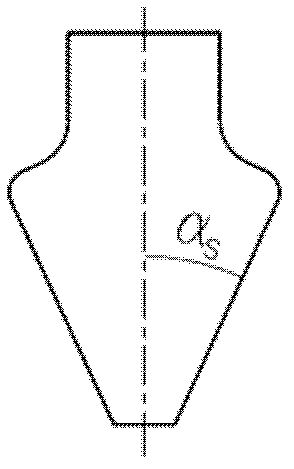

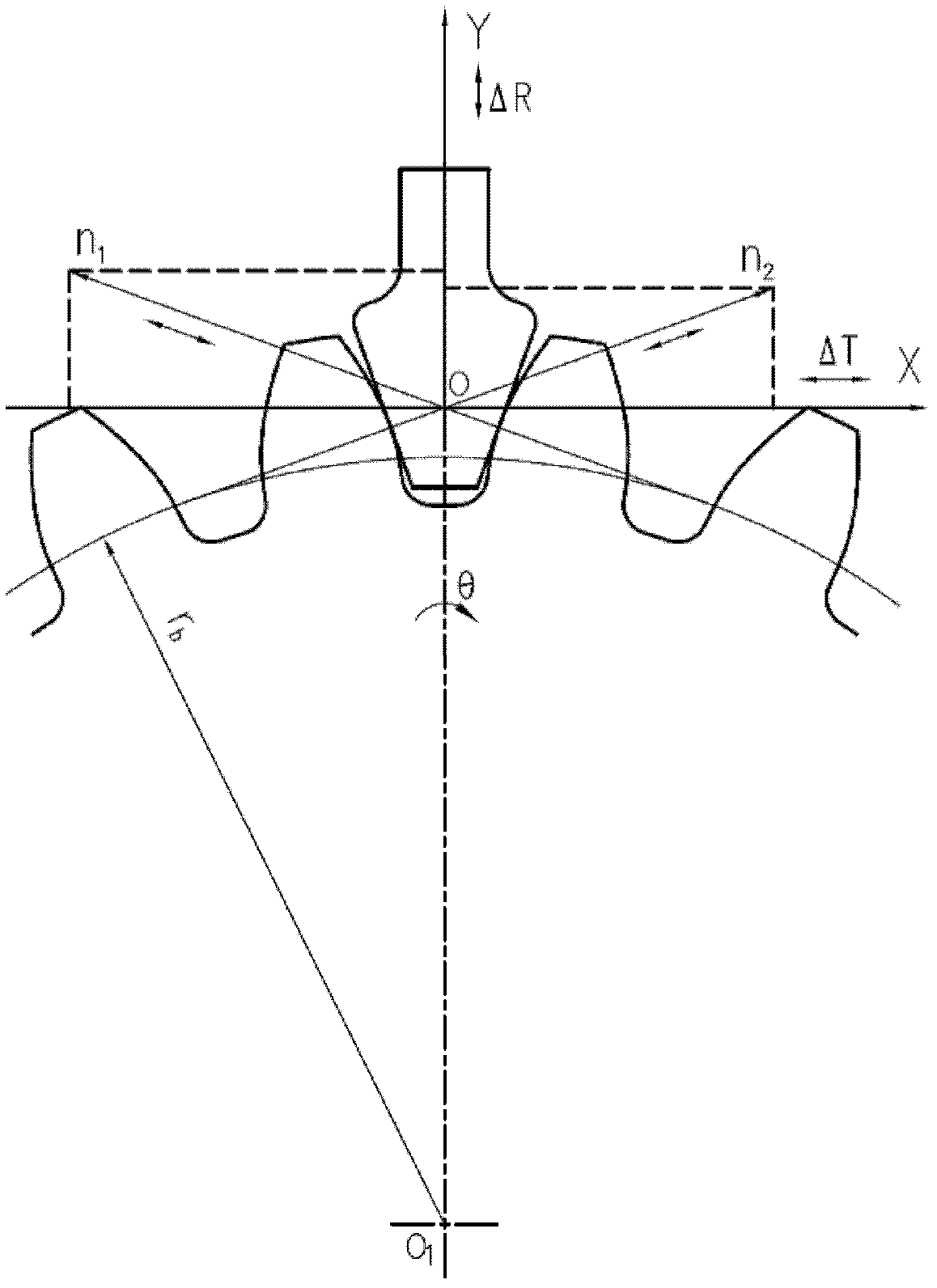

[0057] 1) The basic parameters of the known gear to be tested are as follows: z=18, m=2, α=20°; the basic parameters of the paired gear of the tested gear are as follows: z 1 =24, m=m 1 = 2, α = 20°;

[0058] According to the basic knowledge of gears, it can be concluded that:

[0059] Measured gear index circle radius: r = 1 2 mz = 18 mm

[0060] Radius of the base circle of the gear under test: r b =rcosα=16.9145mm

[0061] Radius of tooth tip circle of tested gear: r a = r + h a * m = ( 18 + 1 × 2 ) mm ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com