Safe anti-counterfeiting structure for wine bottles

A security and anti-counterfeiting, wine bottle technology, which is applied in the direction of preventing repeated filling of containers, closing, packaging, etc., can solve the problems of assembly difficulty, high assembly difficulty, anti-counterfeiting failure, etc., to facilitate assembly, improve production efficiency, and increase safety. sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

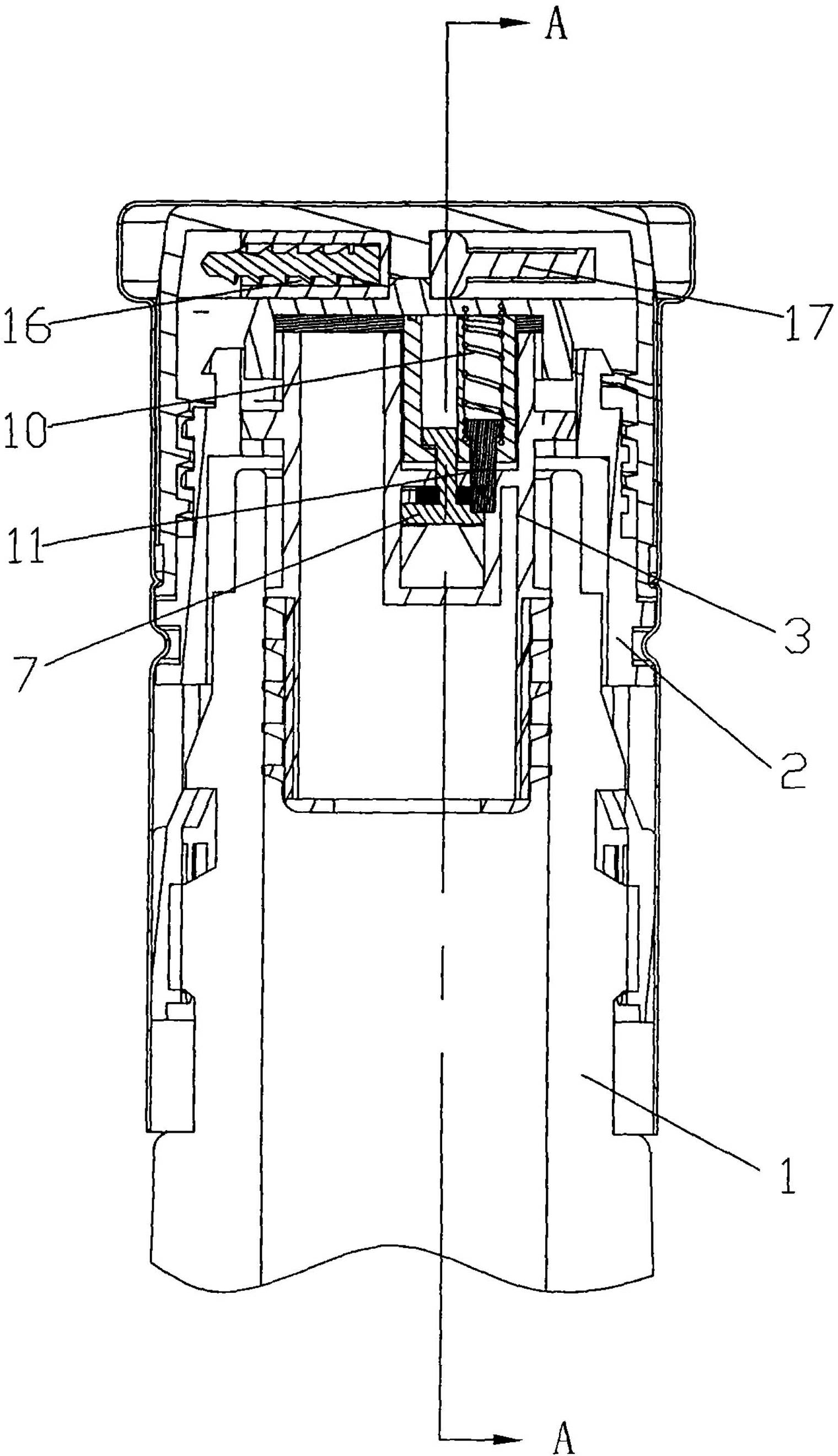

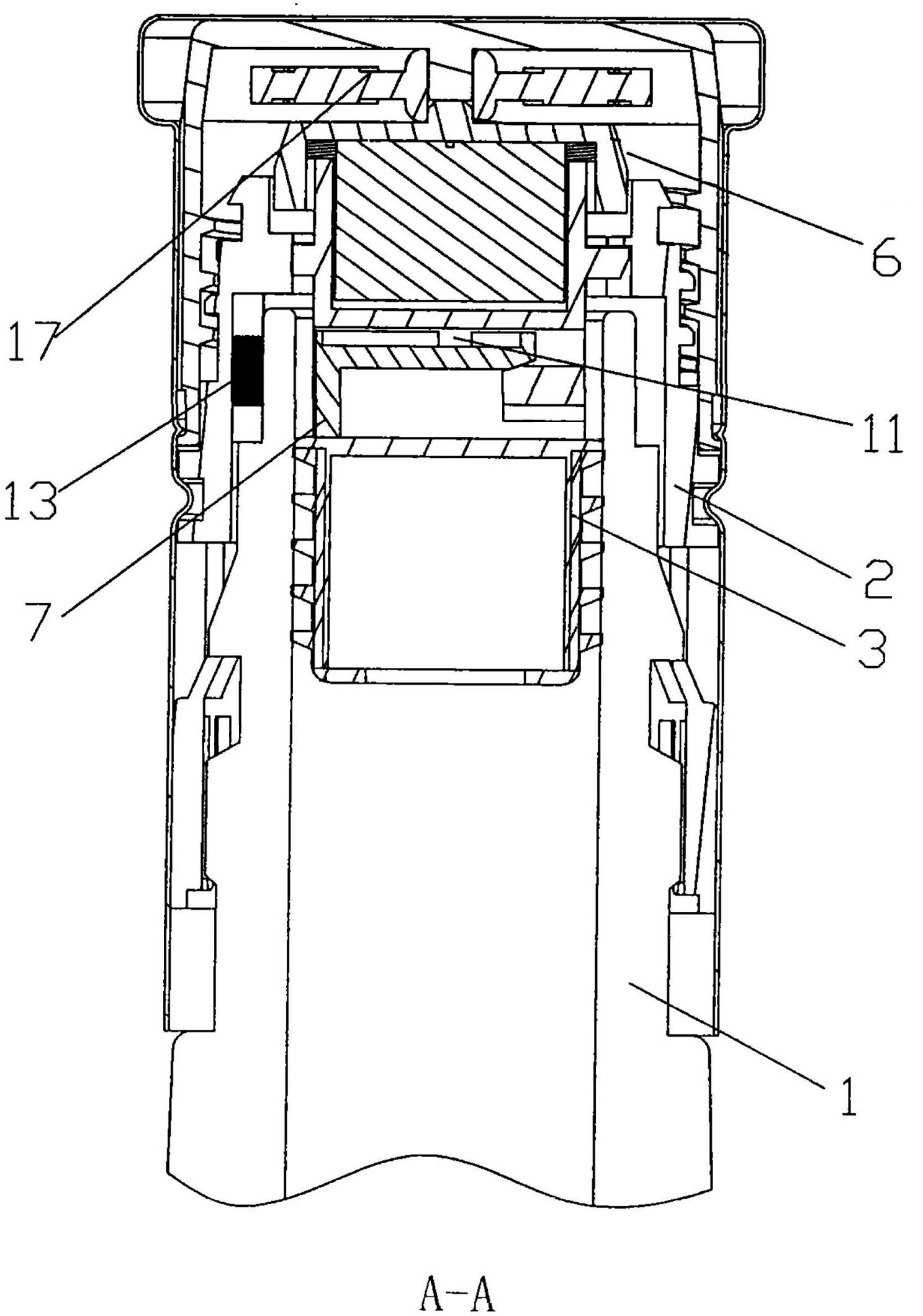

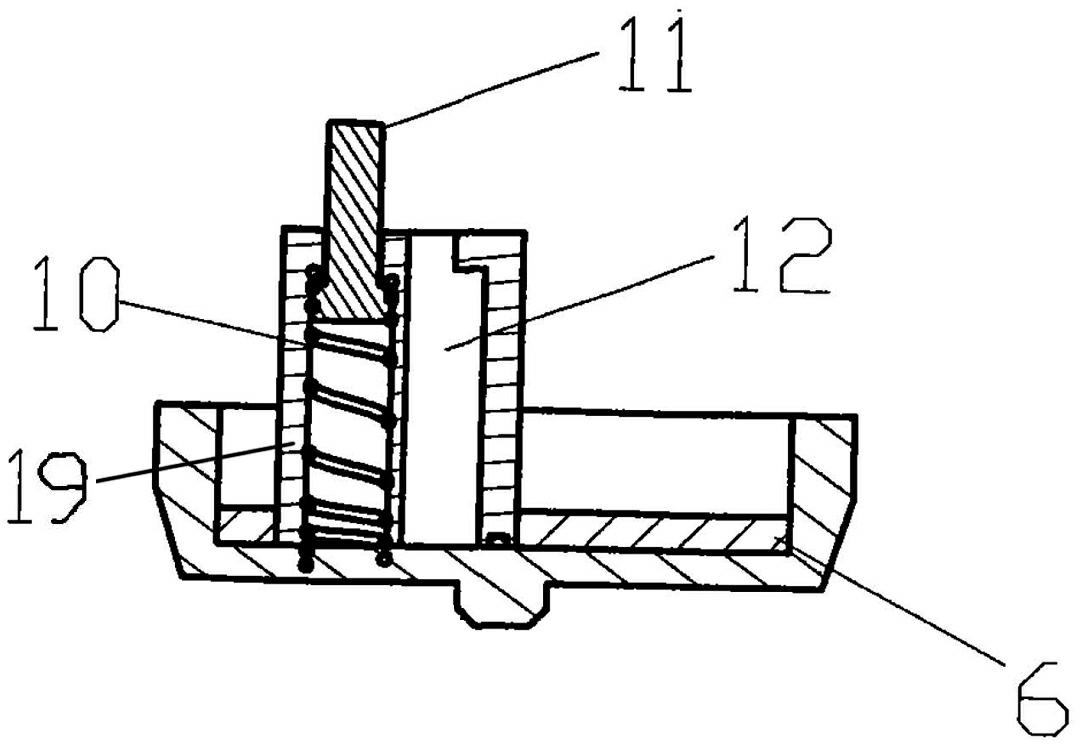

[0038] Such as Figure 4 to Figure 9 As shown, the present invention discloses a wine bottle safety and anti-counterfeiting structure, which includes an outer cover a, an inner cover b, a plastic bottle mouth c, an inner plug d, a sealing cover e and a key f, etc.; the plastic The bottle mouth c is set on the bottle mouth, the inner plug d is embedded in the bottle mouth, the sealing cap e is locked with the inner plug d through the slider g, the key f is placed on the upper part of the sealing cap e, and the inner cap B is that key g and seal cap e are sleeved and movably matched on the plastic bottle mouth c, and outer cover a is to be placed on the wine bottle bottle mouth outside whole inner cover b, plastic bottle mouth c. The sealed wine bottle cannot be poured. The side wall of the wine bottle mouth must be destroyed to release the locking relationship between the inner plug d and the sealing cap e, so that the sealing cap e can be taken out from the inner plug d, there...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com