Side-opening double-leaf two-way opening and closing steel fireproof door and manufacturing method thereof

A technology of side-opening and fire-proof doors, which is applied in the direction of fire-proof doors, wing leaf openers, wing leaf closers, etc. It can solve the problems of no two-way opening, failure to guarantee the sealing effect, and ensure the sealing effect, so as to prolong the service life, Good fire and smoke prevention effect, guarantee the effect of sealing effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

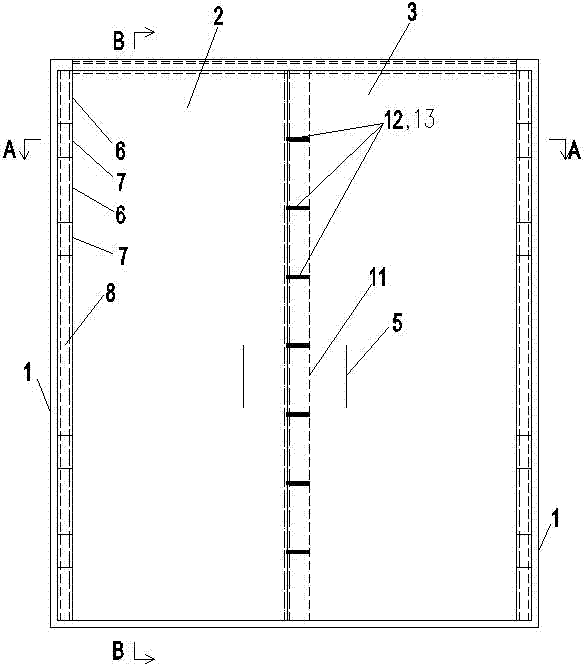

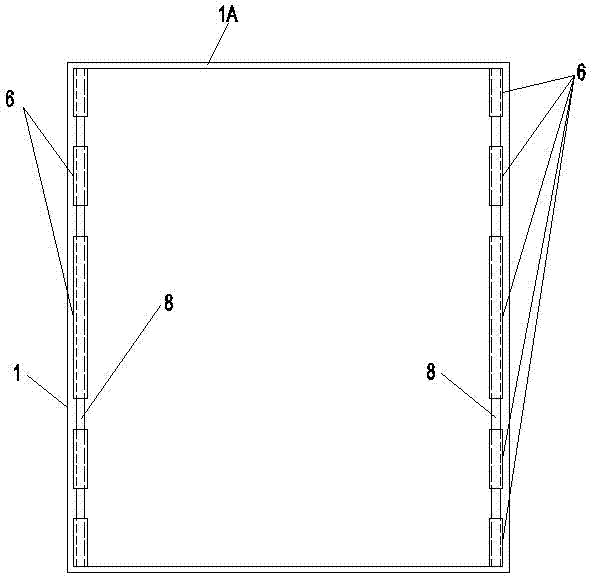

[0045] like Figure 1 to Figure 10 As shown, the side-opening double-leaf two-way opening and closing steel fire door of the present invention includes a steel door frame 1 and a steel door leaf. When in use, the steel door frame 1 is fixedly connected to the tunnel wall 4 and forms the outer boundary of the fire door. The door leaves include a first door leaf 2 and a second door leaf 3, and the first door leaf 2 and the second door leaf 3 are rotatably connected to the door frame 1 through a steel sleeve hinge structure. Both sides of the first door leaf 2 and the second door leaf 3 are provided with handles 5 .

[0046] like Figure 1 to Figure 4 As shown, the steel sleeve hinge structure includes a steel frame sleeve hinge sleeve 6 fixedly connected to the door frame 1, a steel fan sleeve hinge sleeve 7 fixedly connected to the door leaf, and a hinge sleeve installed on the frame sleeve. Cover 6 and the steel sleeve shaft hinge core 8 in the fan cover shaft hinge sleeve 7...

Embodiment 2

[0065] The difference between this embodiment and Embodiment 1 is that the manufacturing method of the flat-opening double-leaf two-way opening and closing steel fire door is different, and the manufacturing method of this embodiment is carried out in the following steps:

[0066] 1. Make a steel door frame 1 with bumper posts 16 on the upper beam, and fix the door frame 1 with the tunnel wall 4;

[0067] 2. Make the frame sleeve shaft hinge sleeve 6, the fan sleeve shaft hinge sleeve 7 and the sleeve shaft hinge core 8, and put the frame sleeve shaft rubber sleeve and the fan sleeve shaft hinge sleeve 7 on the sleeve shaft hinge core 8 alternately;

[0068] 3. Fix the upper and lower ends of the shaft hinge core 8 on the door frame 1, and connect the frame sleeve shaft hinge sleeve 6 with the door frame 1;

[0069] 4. Make the door leaf, including the first door leaf 2 and the second door leaf 3, make steel column grooves on the upper end faces of the first door leaf 2 and th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com