Liquid discharging apparatus and control method thereof

A control method and liquid technology, applied in printing devices, printing, etc., can solve problems such as leakage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

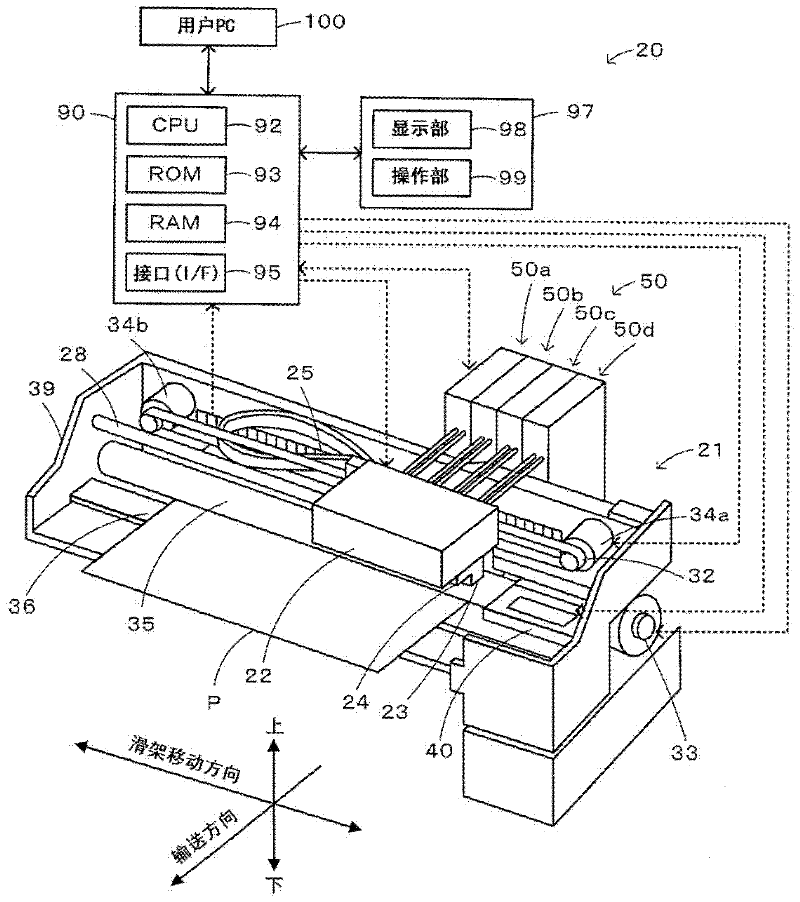

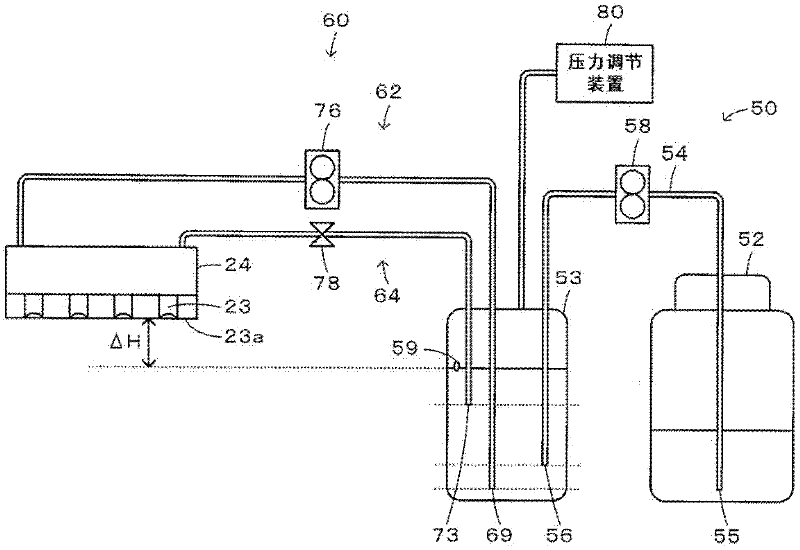

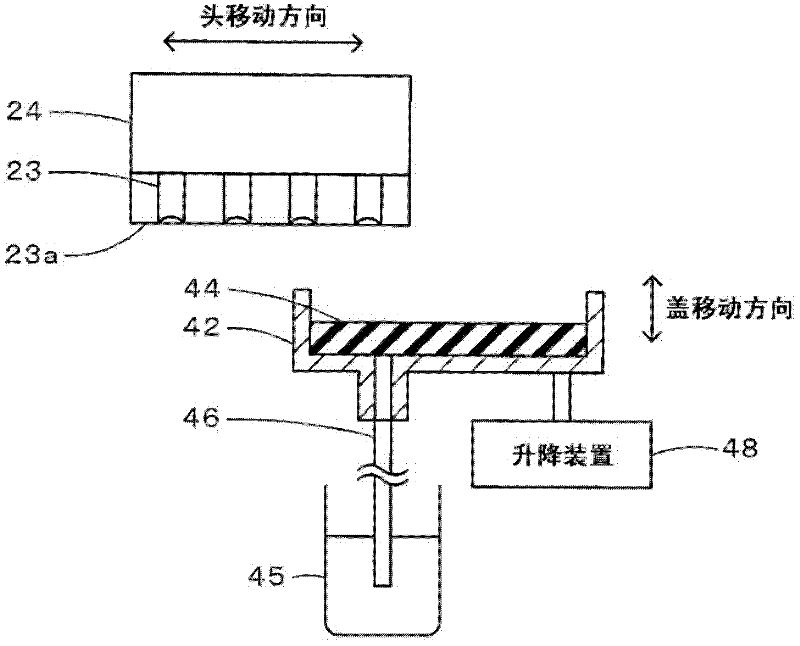

[0024] Embodiments of the present invention will be described below using the drawings. figure 1 is a configuration diagram showing an outline configuration of an inkjet printer 20 as an embodiment of the present invention, figure 2 is a structural diagram showing an outline of the structure of the ink circulation system 50, image 3 It is a configuration diagram showing the outline of the configuration of the capping device 40 .

[0025] Such as figure 1 As shown, the inkjet printer 20 of this embodiment includes: a printer mechanism 21 that ejects ink droplets from the plurality of nozzles 23 formed on the print head 24 to the paper P conveyed on the platen 36 to implement Printing process; capping device 40, which is arranged near the right end of platen 36, and can independently seal the plurality of nozzles 23 of printing head 24; controller 90, which controls the entire device; operation panel 97, which has a display unit 98 for notifying the user of various informat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com