Novel locking fastener

A new type of loose fastener technology, applied in the direction of threaded fasteners, locking fasteners, connecting components, etc., can solve the problems of looseness, low reliability of nut pads, difficult processing, etc., to prevent thread loosening, Good use effect, anti-loosening effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

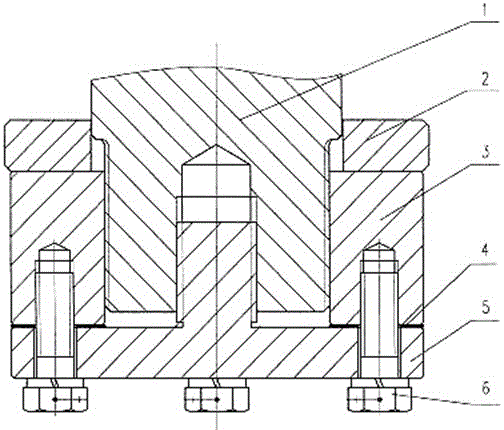

Image

Examples

Embodiment 1

[0019] Embodiment 1: A novel anti-loosening fastener, it comprises that it comprises screw mandrel 1, nut 3, gland 5, locking screw 6, adjusting gasket 4, it is characterized in that: when nut 3 wants to loosen due to long-term vibration impact When disengaged, the screw 1 does not move, the nut 3 rotates, the end surface of the nut 3 and the gland 5 are rigidly connected by the locking screw 6, and the head of the gland 5 is screwed into the screw 1 due to the thread of another direction of rotation. The movement trends of the two threads are different, thereby completely suppressing the loosening of the nut 4 . The invention is applied in a straightening machine system, and avoids the loosening of threads caused by long-term repeated vibration and impact.

Embodiment 2

[0020] Embodiment 2: It is basically the same as Embodiment 1, except that the nut 3 itself adopts an inner locking screw, thereby further restraining the loosening of the thread.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com