Fastener with anti-loosening function

A fastener and function technology, applied in the field of fasteners with anti-loosening function, can solve the problems of easy loosening of bolts and nuts and poor tightening effect of fasteners.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

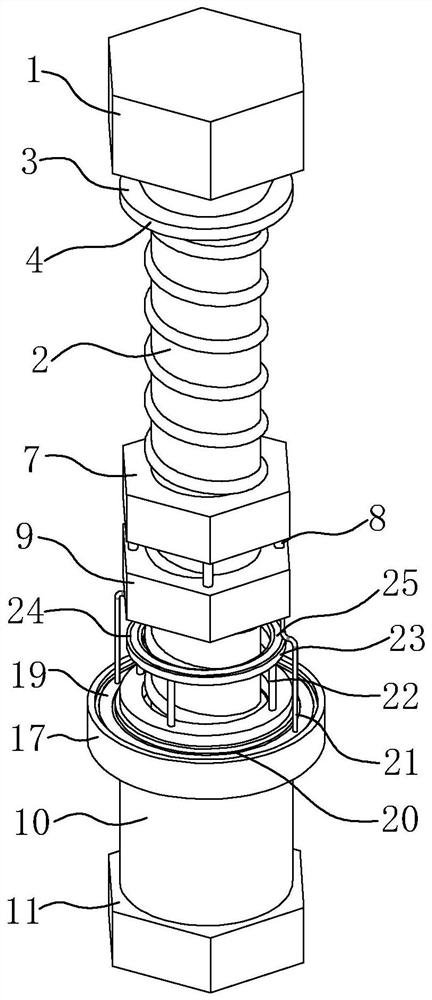

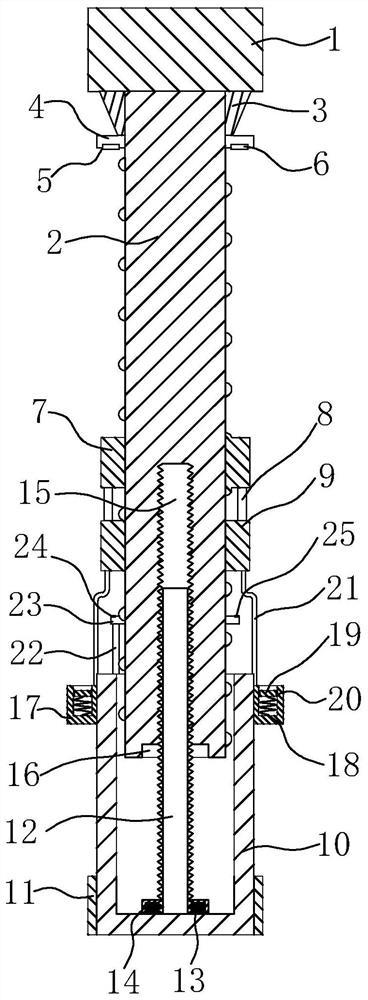

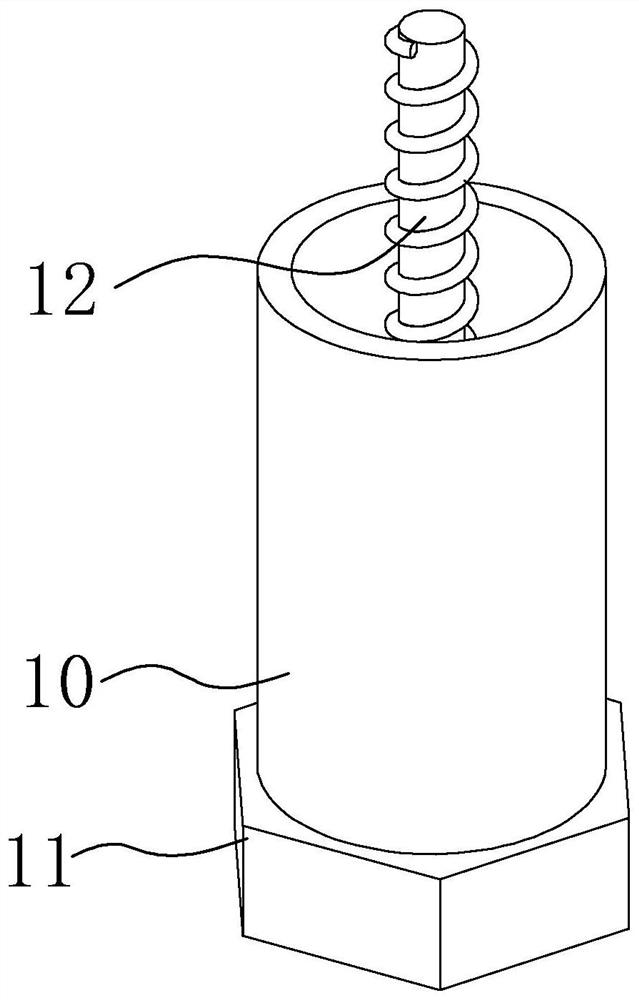

[0021] refer to Figure 1-4 , a fastener with anti-loosening function, comprising a bolt head 1, the bottom end of the bolt head 1 is connected with a threaded section 2, the upper end of the threaded section 2 is connected with a raised ring 3, and the upper end of the raised ring 3 is connected with the bolt head 1. The first nut 7 is connected to the threaded section 2, the second nut 9 is connected to the threaded section 2, the second nut 9 is located below the first nut 7, and the bottom end of the first nut 7 is connected with several first connections Rod 8, one end of each first connecting rod 8 is connected to the second nut 9, the first nut 7, the first connecting rod 8 and the second nut 9 are integrally structured, the threaded section 2 runs through the object, and the first nut 7 is rotated, The first nut 7 drives the second nut 9 to rotate through the first connecting rod 8, and the upper end of the first nut 7 is in contact with the object.

[0022] The botto...

Embodiment 2

[0024] refer to Figure 1-4 , as another preferred embodiment of the present invention, the difference from Embodiment 1 is that the support frame includes several third connecting rods 22, and one end of each third connecting rod 22 is connected to the hollow sleeve 10, and each third connecting rod The other end of 22 is connected with the second fixing ring 23, the upper end of the second fixing ring 23 is provided with the third groove 24, the second elastic pad 25 is connected in the third groove 24, the third connecting rod 22 fixes the second The fixing ring 23, the second fixing ring 23 supports the second nut 9 to prevent the second nut 9 from loosening.

Embodiment 3

[0026] refer to Figure 1-4 , as another preferred embodiment of the present invention, on the basis of Embodiment 1, the bottom end of the protruding ring 3 is connected with a first fixed ring 4, the first fixed ring 4 is in contact with the object, and the object is limited, and the screw thread Section 2 passes through the first fixed ring 4, the lower surface of the first fixed ring 4 is provided with a first groove 5, the first elastic pad 6 is connected in the first groove 5, and the outer upper end of the hollow sleeve 10 is connected with a hollow frame 17 , the hollow frame 17 is connected with several springs 18, the upper end of the spring 18 is connected with a movable plate 19, the movable plate 19 cooperates with the hollow frame 17, the both sides of the movable plate 19 are connected with sealing rings 20, each sealing ring 20 One side of each second connecting rod 21 is connected with the second nut 9, and the hollow sleeve 10 drives the hollow frame 17 move...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com