Automatic pasty-material-cleaning stirrer

An automatic cleaning and mixer technology, which is applied to equipment in the pharmaceutical field and chemical field, can solve the problems of difficult cleaning of paste materials and unsatisfactory effects, and achieve the effect of easy cleaning.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0013] The present invention will be further described below in conjunction with the accompanying drawings.

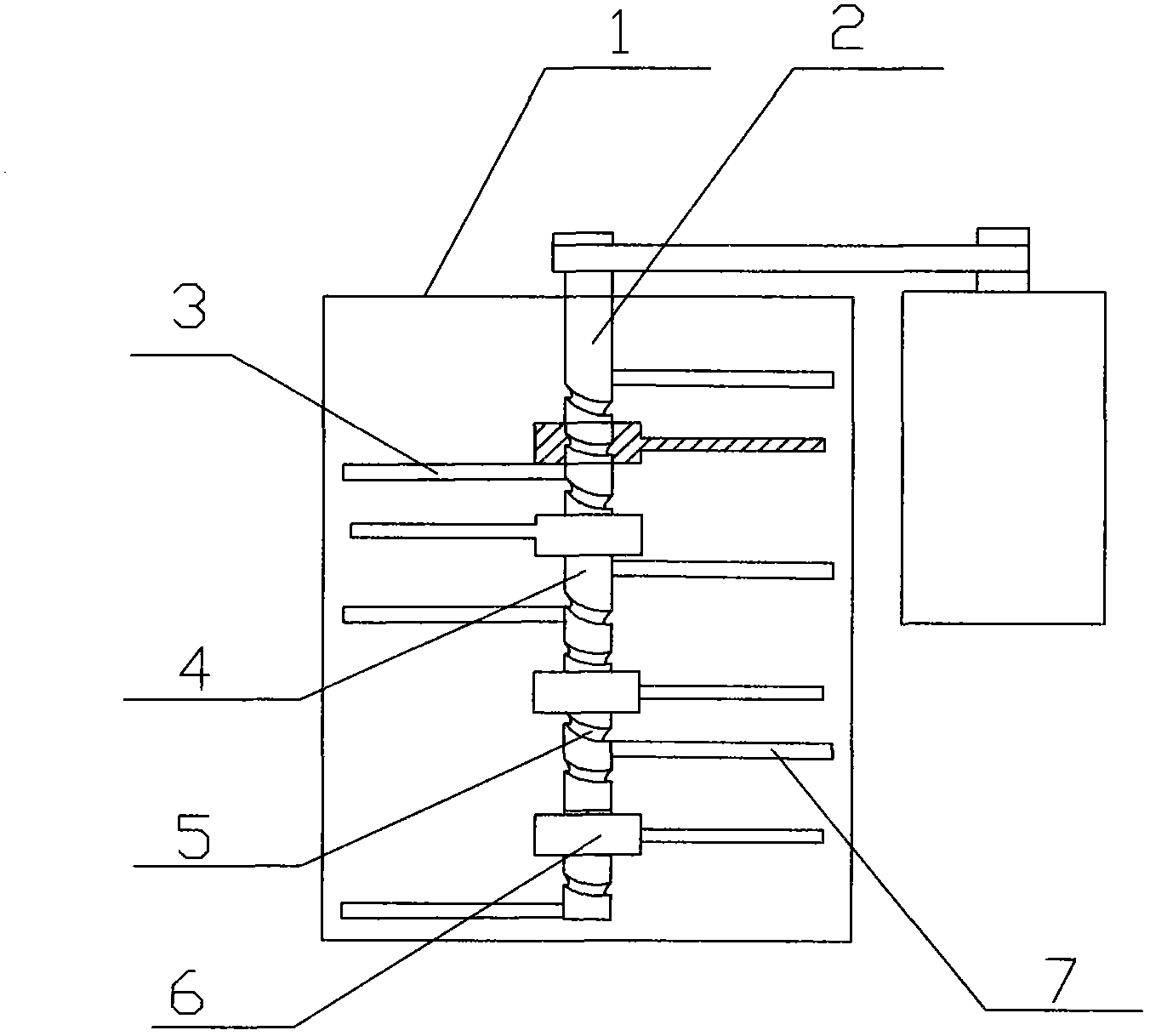

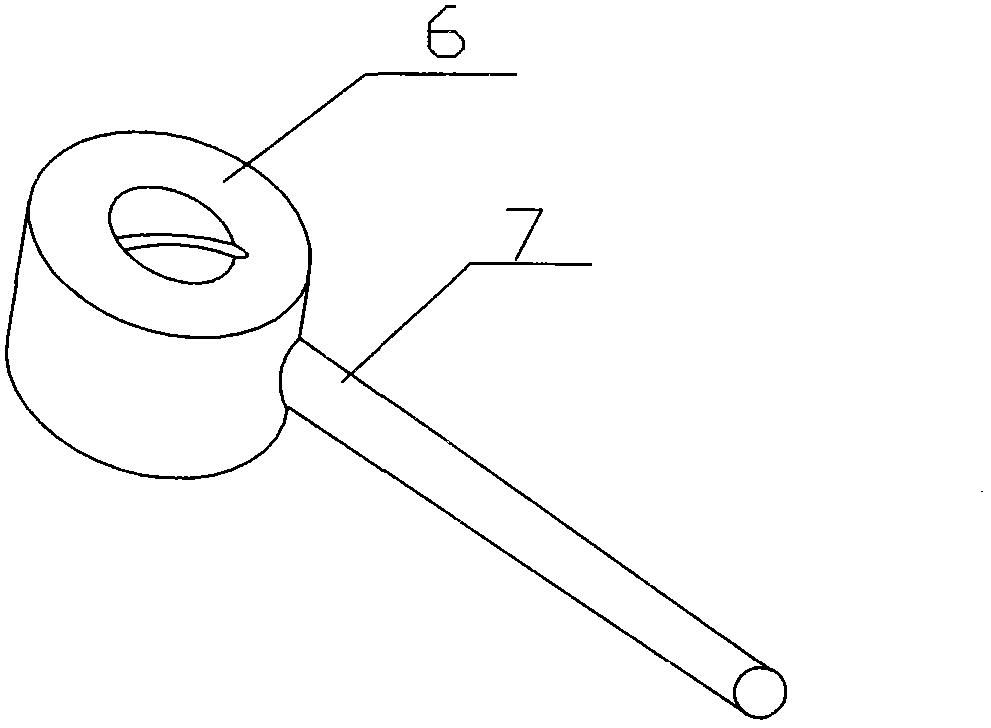

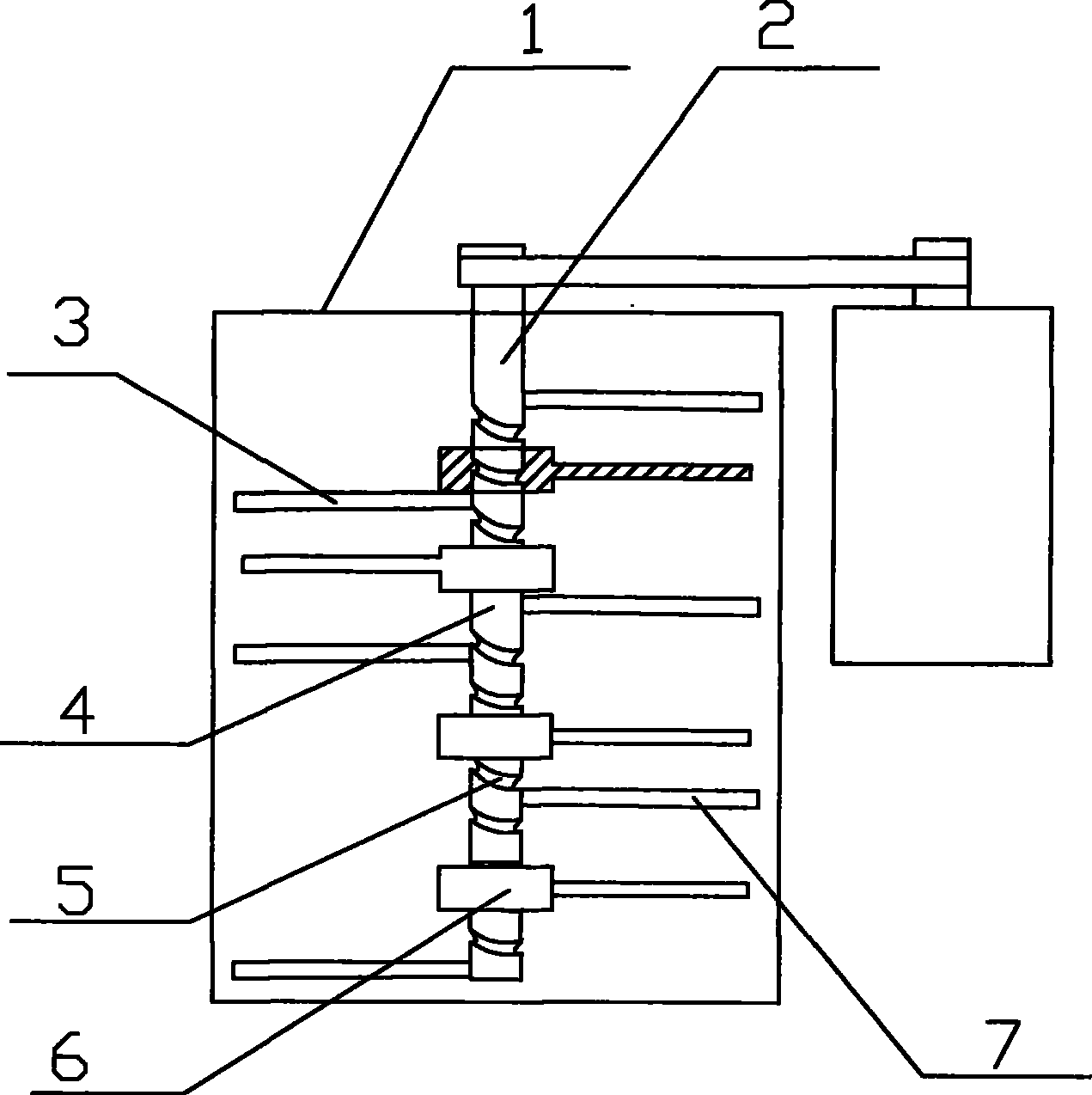

[0014] Such as figure 1 As shown, the automatic cleaning paste material mixer includes a mixer body 1, the mixer body 1 has a stirring shaft 2, and the stirring shaft 2 is made of a plurality of stirring blades 3 installed on the shaft core 4, and is characterized in that: The outside of the shaft core 4 has a coiled shaft chute 5, and a sleeve 6 is sleeved outside the shaft, and the sleeve 6 has a sleeve chute matching the shaft chute.

[0015] When the mixing is completed, there are less materials in the mixer, and there are more materials on the shaft core. If you continue or stop, the kit will slide up the shaft, slide on the shaft core of the adjacent connecting blade, and put the shaft core on the shaft core. The material is rubbed off to play a cleaning effect.

[0016] Further speaking, at least one of the contact parts of the shaft chute and the sleeve chute...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com