Ultrasonic automatic flaw detection arm for high-curvature composites

A composite material, large curvature technology, applied in the analysis of materials, material analysis using sonic/ultrasonic/infrasonic waves, instruments, etc., can solve the problems of automatic flaw detection of workpieces that cannot adapt to large radius of curvature, large size, complex structure, etc., to achieve expansion The effect of flaw detection curvature range, improving structure compactness, and improving flaw detection accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

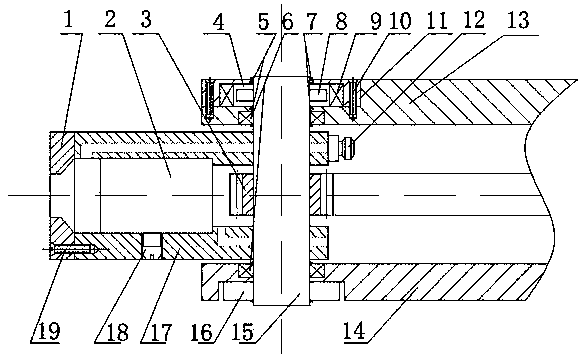

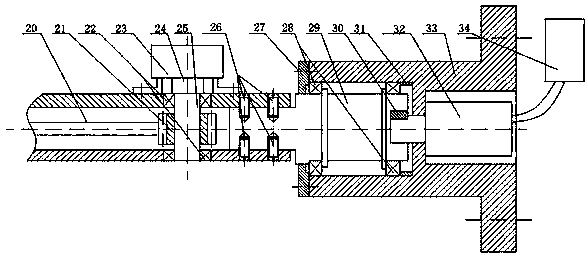

Embodiment 1

[0029] The large-curvature composite material ultrasonic automatic flaw detection arm of this embodiment includes an ultrasonic probe part, a magneto-rheological fluid damper, a micro encoder 16, a timing belt device, a support plate, a connecting shaft 29, a connecting plate 33, and a probe-driven servo motor 23 , the support plate rotating servo motor 32 and the control unit 34; the synchronous belt device is vertically fixedly installed on the support plate, the transverse end of the synchronous belt device is equipped with an ultrasonic probe part, and the magnetorheological fluid damper and the miniature encoder 16 are installed on the support plate On the transverse end and the synchronous belt device, the transverse start of the support plate is connected to the connecting shaft 29 through the support plate fixing screw 26, and the connecting shaft 29 is fixedly connected to the connecting disc 33 through the connecting shaft bearing 28, and the transverse end of the conn...

Embodiment 2

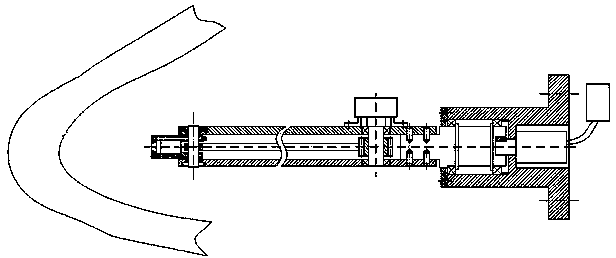

[0042] Two sets of automatic flaw detection arms of Embodiment 1 can be installed on the flaw detector with two sets of degrees of freedom in the X, Y, and Z directions through the connecting plate 33, and the ultrasonic transmission method can be used to realize large-scale Ultrasonic automatic flaw detection of curvature composite materials.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com