Method for electrolytic disinfection of recirculated cooling water

A technology of circulating cooling water and cooling water, which is applied in the direction of sterilization/microdynamic water/sewage treatment, etc., and can solve the problem of low sterilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

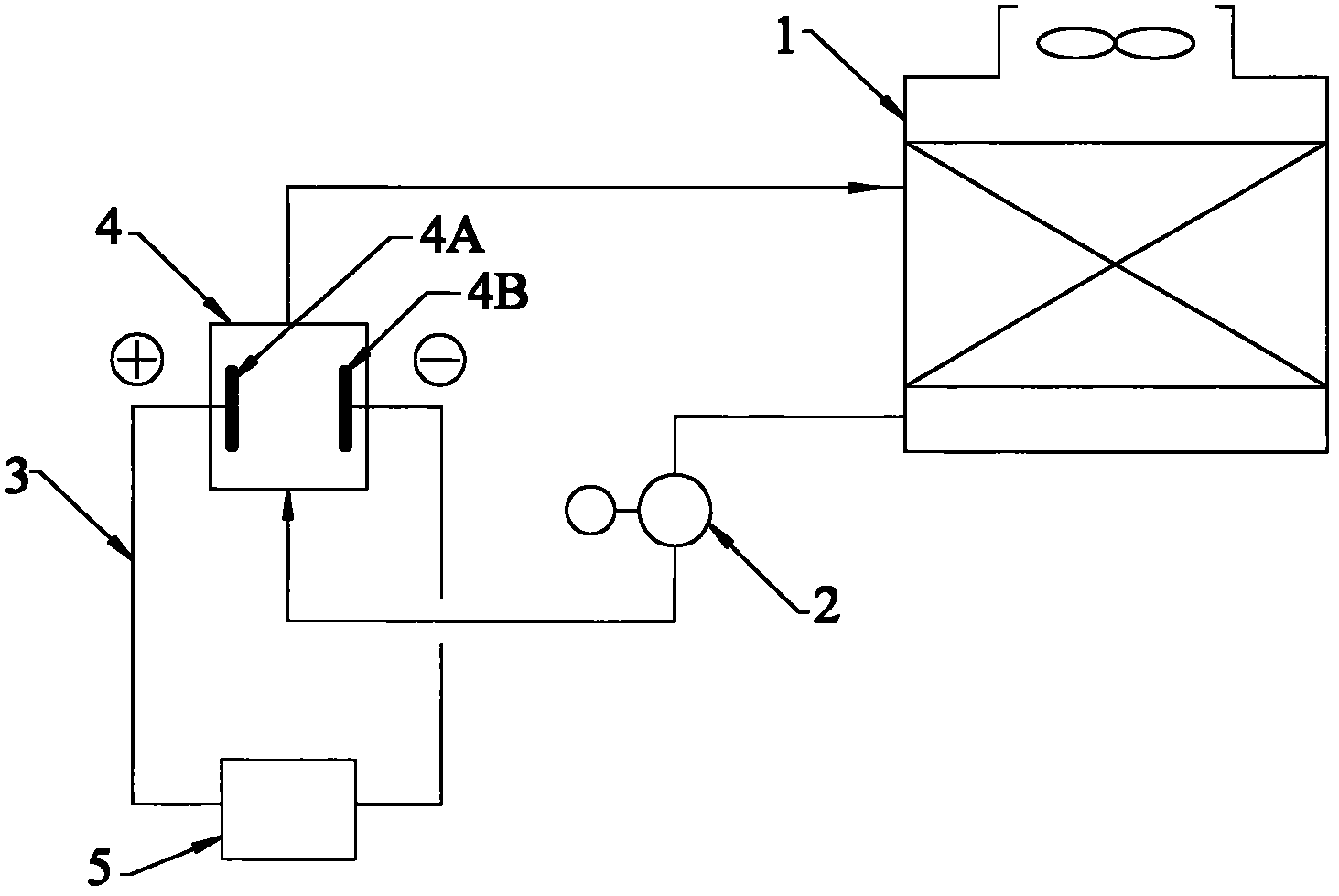

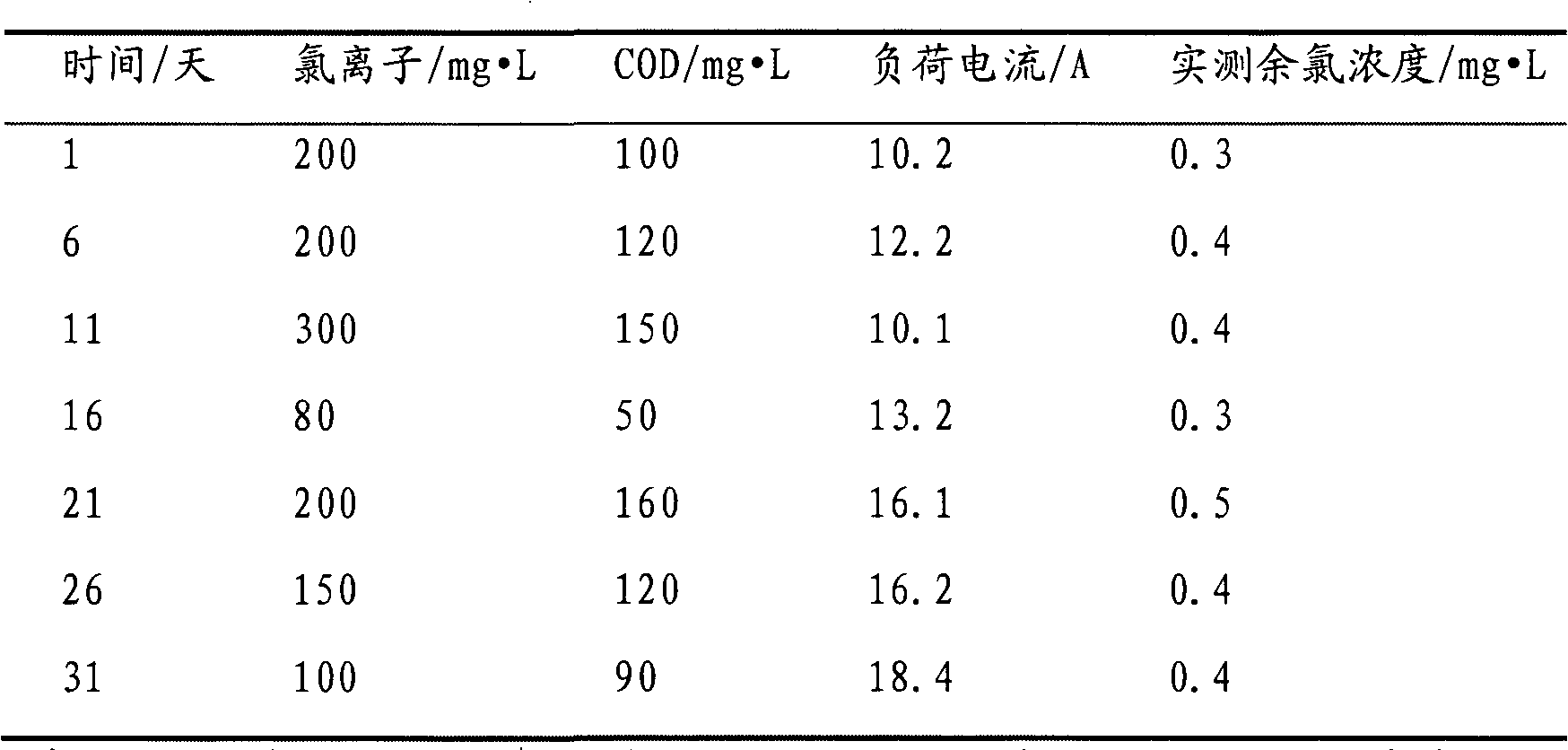

[0039] Electrolytic sterilization of a circulating cooling water system, the process is as follows figure 1 As shown, the circulating water volume is 100m 3 / h, the target residual chlorine concentration of the cooling water system is 0.4mg / L, and it runs continuously for 31 days.

[0040] First, the concentration of chlorine ions in the cooling water was analyzed to be 200mg / L, and the COD value was 100mg / L.

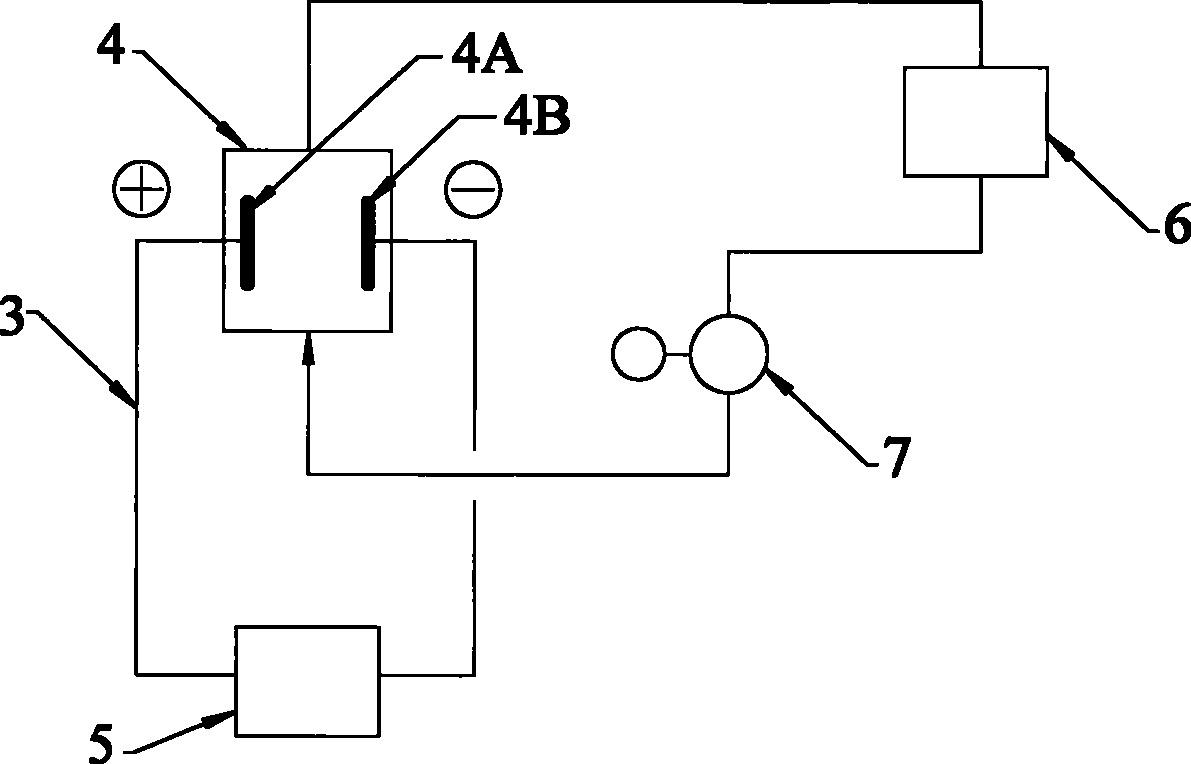

[0041] Secondly, calculate the coefficient a to determine the relationship between the generation rate of active chlorine and the current and concentration of chloride ions. For this purpose build as figure 2 In the test device shown, the chloride ion concentration in the test water is 200mg / L, the COD is 0mg / L, the calcium hardness and conductivity are the same as the cooling water, and the test water volume is 10m 3 , run for 1h.

[0042] Set the electrolysis current to 10A, and the measured residual chlorine concentration is 0.2mg / L. According to the residual ch...

Embodiment 2

[0051] Electrolytic sterilization of a circulating cooling water system, the process is as follows figure 1 As shown, the circulating water volume is 80m 3 / h, the target residual chlorine concentration of the cooling water system is 0.3mg / L, and it runs continuously for 31 days.

[0052] First, the concentration of chloride ions in the cooling water was analyzed to be 150mg / L, and the COD value was 80mg / L.

[0053] Secondly, calculate the coefficient a to determine the relationship between the generation rate of active chlorine and the current and concentration of chloride ions. Using the same test device as in Example 1, since a is only related to the electrode size, material, and electrode spacing, the coefficient a=0.001. The relationship between the generation rate of active chlorine and the current and chloride ion concentration is:

[0054] Active chlorine generation rate (g / h) = 0.001 × chloride ion concentration (mg / L) × current (A)

[0055] Then, in figure 1 Whe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com