Method for fabricating disposable packing box

A production method and packaging box technology, applied in box production operations, packaging, rigid/semi-rigid container manufacturing, etc., can solve the problem of imitation of anti-counterfeiting marks, consumers cannot see products clearly, consumers cannot distinguish them well, etc. problems, to achieve the effect of eliminating counterfeit and shoddy products

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

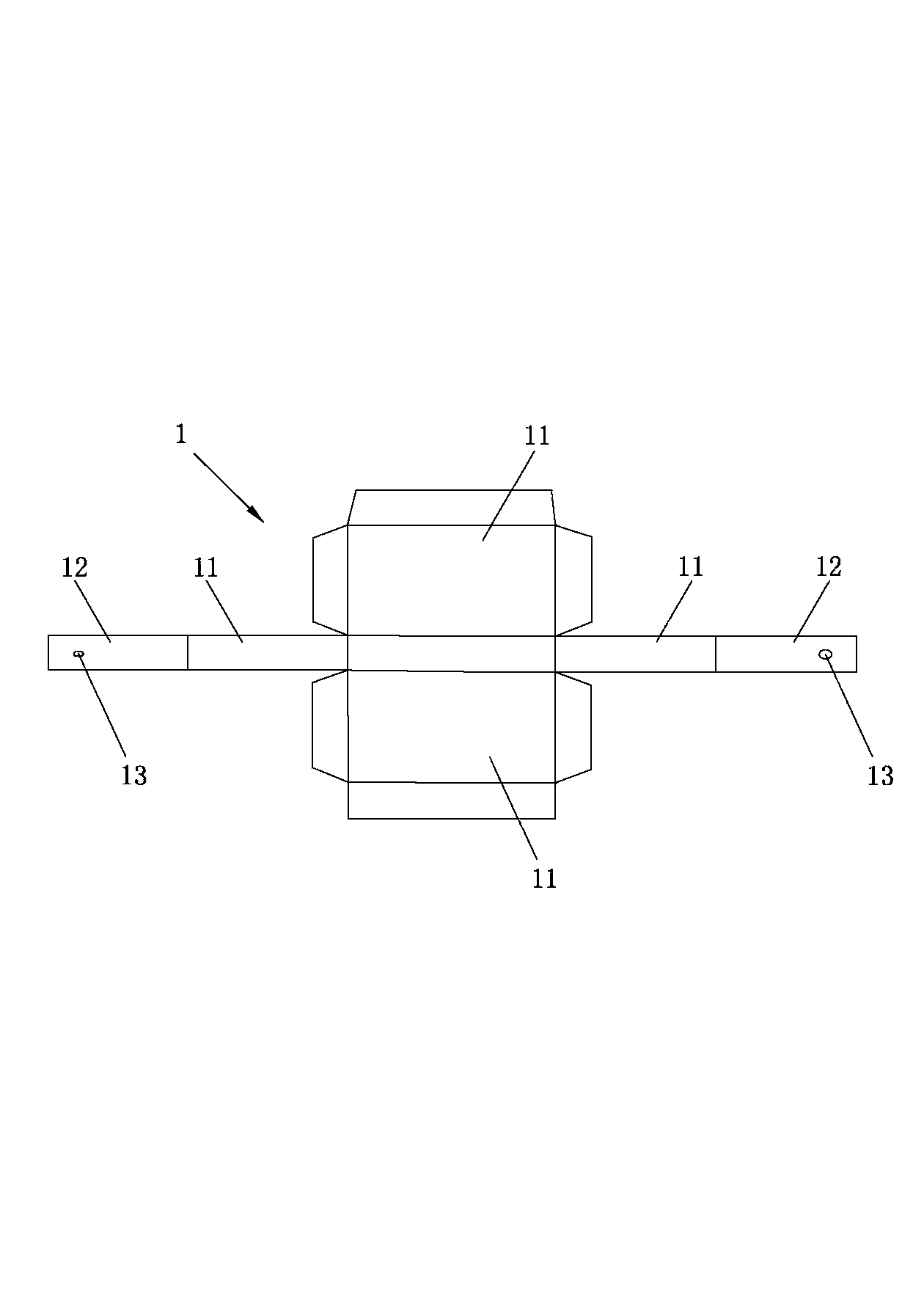

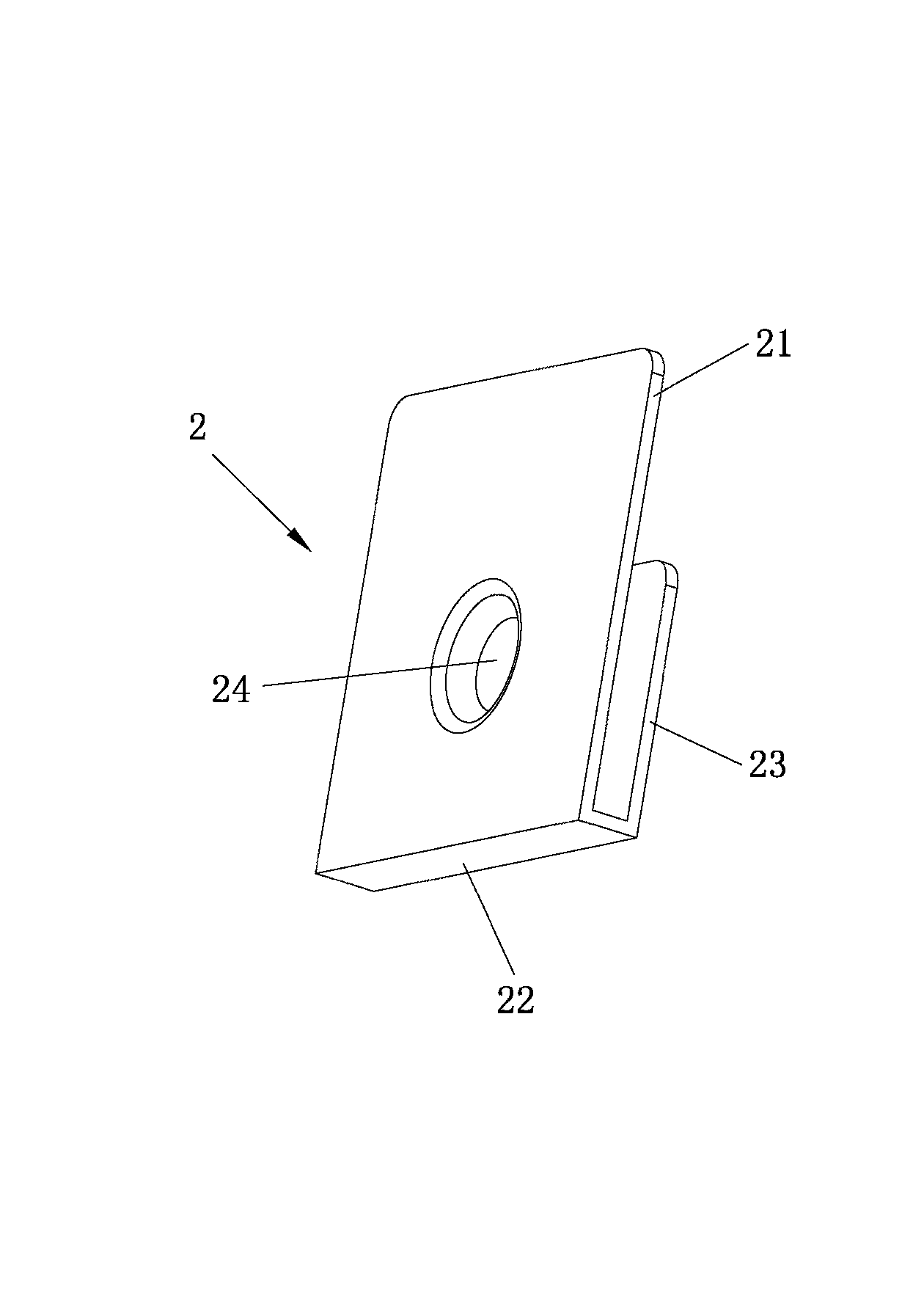

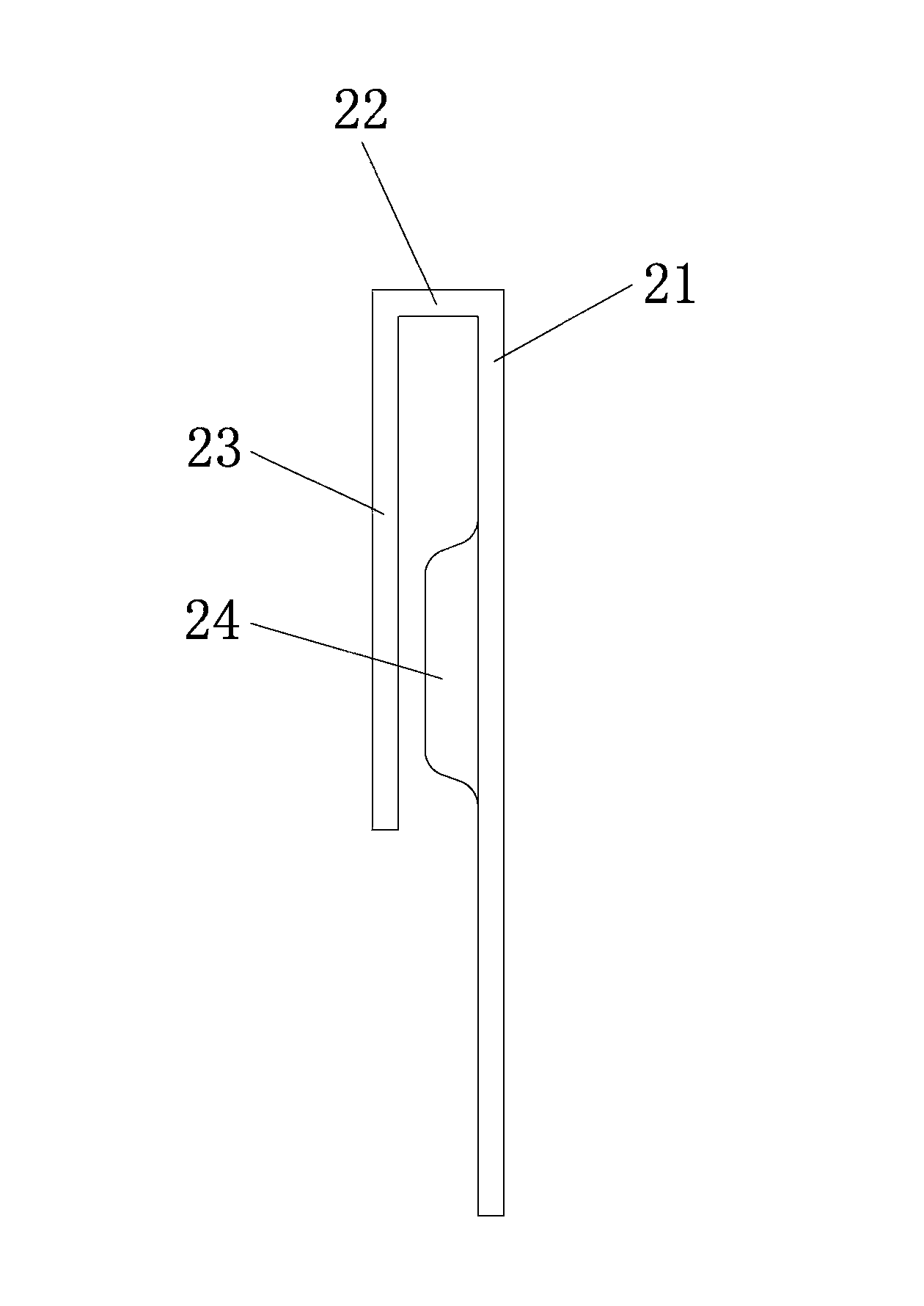

[0038] Such as Figure 1~Figure 5 As shown, a method for making a disposable packaging box includes the following preparation steps: (a) take a box body 1 with a side edge 11 and at least two folded edges 12, and open a punching hole 13 at each folded edge 12; ( b) Overlap at least two folded sides 12 so that the punched holes 13 of each folded side 12 are aligned; (c) Take a closure 2, the closure 2 includes an upper flap 21, a side flap 22 and a lower flap connected in sequence 23, a pit 24 is set on the upper flap 21 or the lower flap 23 of the closure 2; (d) clamp the closure 2 to the overlapping folding edge 12, and the upper flap 21 is located above the overlapping folding edge 12 , the lower flap 23 is located below the overlapping folded edge 12, and the pit 24 is aligned with the punching hole 13; (e) welding the upper flap 21 and the lower flap 23 at the pit 24.

[0039] A manufacturing method of a disposable packaging box according to the present invention, clamps ...

Embodiment 2

[0048]The difference between this embodiment and Embodiment 1 is: this embodiment also includes a step (a1) after the step (a) and before the step (b): at least one folding edge 12 and side edge 11 A process hole 14 is opened at the joint; the step (d) is specifically: insert the lower flap 23 of the seal 2 into the process hole 14, the seal 2 clamps the overlapping folded edge 12, and the upper flap 21 is located above the overlapping folded edge 12 , the lower flap 23 is located below the overlapped folded edge 12 , and the recess 24 is aligned with the punched hole 13 .

[0049] Such as Image 6 As shown, there are four folding sides 12 in this embodiment, and the four folding sides 12 are arranged on the same side of the side side 11 . With four folded edges 12, the packing is tighter. Such as Image 6 , Figure 7 As shown, a process hole 14 is opened at the junction of at least one folded edge 12 and the side edge 11 , and the lower flap 23 of the closure 2 is inserte...

Embodiment 3

[0053] The difference between this embodiment and Embodiment 1 is that this embodiment also includes a step (c1) after the step (c) and before the step (d): on the upper flap 21 of the closure 2 The surface is provided with an anti-counterfeiting identification layer.

[0054] The step (c1) specifically includes: stamping or printing or engraving an anti-counterfeiting label layer on the surface of the upper flap 21 of the closure 2 .

[0055] The anti-counterfeit mark can be set on the surface of the upper flap 21 by stamping / printing / engraving or other methods. The upper flap 21 refers to the side of the closure 2 that consumers can directly observe. The anti-counterfeit mark can be anti-counterfeit characters / patterns / codes, etc.

[0056] Features that are not explained in this embodiment are explained in Embodiment 1, and will not be repeated here.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com