High-speed unreeling device for thin film intermittent feed and control method

A control method and unwinding device technology, applied in the field of automation, can solve the problems of insufficient compensation of the tension device, easy damage to the film pattern and color, and easy creases on the film, etc., to achieve high dynamic performance and short response time.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

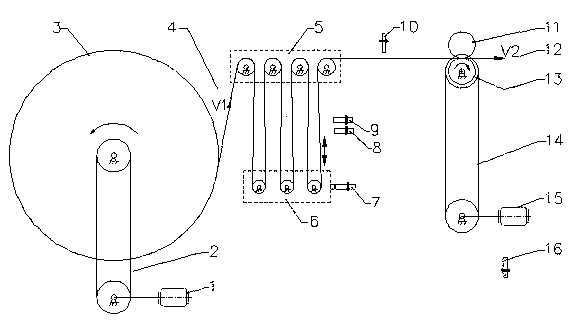

[0016] Below in conjunction with accompanying drawing, describe in detail as follows:

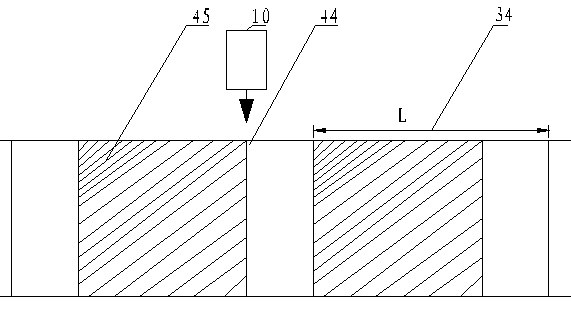

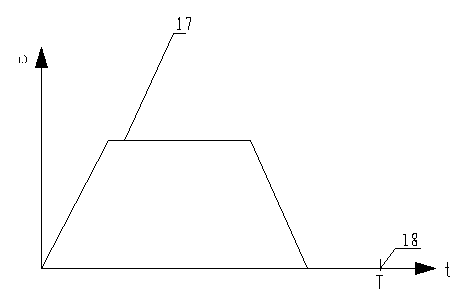

[0017] figure 1 and figure 2 Among them, the film unwinding servo motor 1 is connected with the film roll 3 through the synchronous belt transmission 2, and the corresponding synchronous belt transmission ratio is 1:1, the film feeding servo motor 15 is connected with the traction pair roller 11 via the synchronous belt transmission 14, and the corresponding synchronous belt The transmission ratio is 1:1, the film winds on the buffer roller group 6 and the fixed roller group 5, passes through the traction pair roller 11, the film pulls the buffer roller group 6 to move up and down, and the buffer roller group 6 drops to the bottom When the film deceleration compensation proximity switch 7 is triggered at the end, when the buffer roller group 6 moves upward, the film stop compensation proximity switch 8 just leaves the film stop compensation proximity switch 8, and the film acceleration co...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap