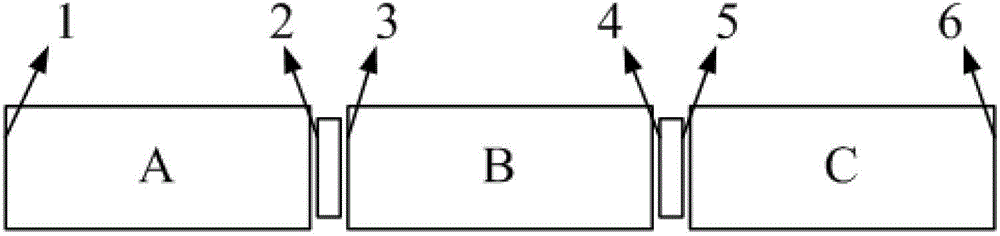

Method utilizing crosshead shoe to reconstitute roller system of continuous casting machine segment

A continuous casting machine segment and cross slider technology, which is applied in the field of continuous casting equipment, can solve the problems of asynchronous rotation of segmented rolls and water leakage of continuous casting machine rolls, so as to improve service life, reduce water leakage, and reduce impact Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

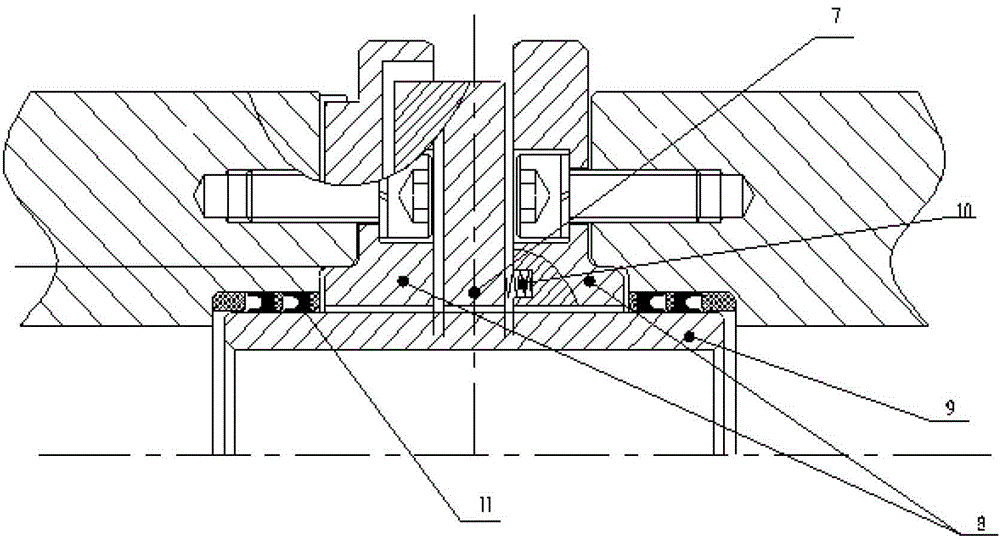

[0019] 1. Replace the end cover (original) with an end cover 8 with a keyway. The size of the end cover 8 with a keyway is φ160*15mm, and the installation space for the cross slider 7 is reserved during installation. On the premise that the position of the bearing seat remains unchanged, the end cover 8 with the keyway can reserve the installation space for the cross slide 7 on the basis of meeting the strength and positioning requirements, which solves the problem of the application of the cross slide 7 mechanism and the two subsections. Space issues for roll connections.

[0020] 2. Set the cross slider 7 in the reserved installation space. The thickness of the cross slider 7 is 12mm; there is a key on the cross slider 7, the key height is 10mm, and the key width is 20mm; The hole size is φ54, and the outer circle size is φ144. The thickness dimension of the cross slider 7 is designed by utilizing the feature of the allowable micro axial displacement of the cross slider 7 ....

PUM

| Property | Measurement | Unit |

|---|---|---|

| size | aaaaa | aaaaa |

| size | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com