Adjustable steering engine fixing device for test

A technology for a fixing device and a steering gear, which is applied in the mechanical field, can solve problems such as the inability to meet the test requirements of the steering gear, and achieve the effects of reducing the cost of retrofit design, low cost and simple equipment.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

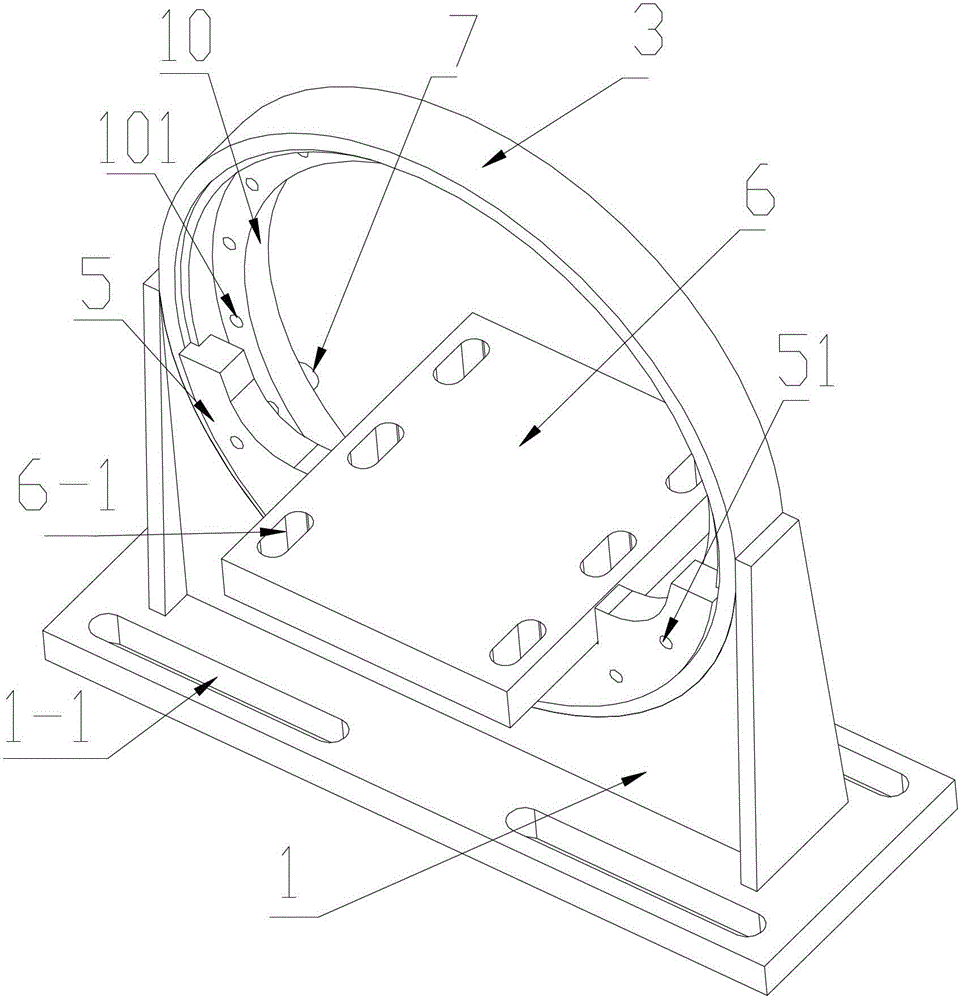

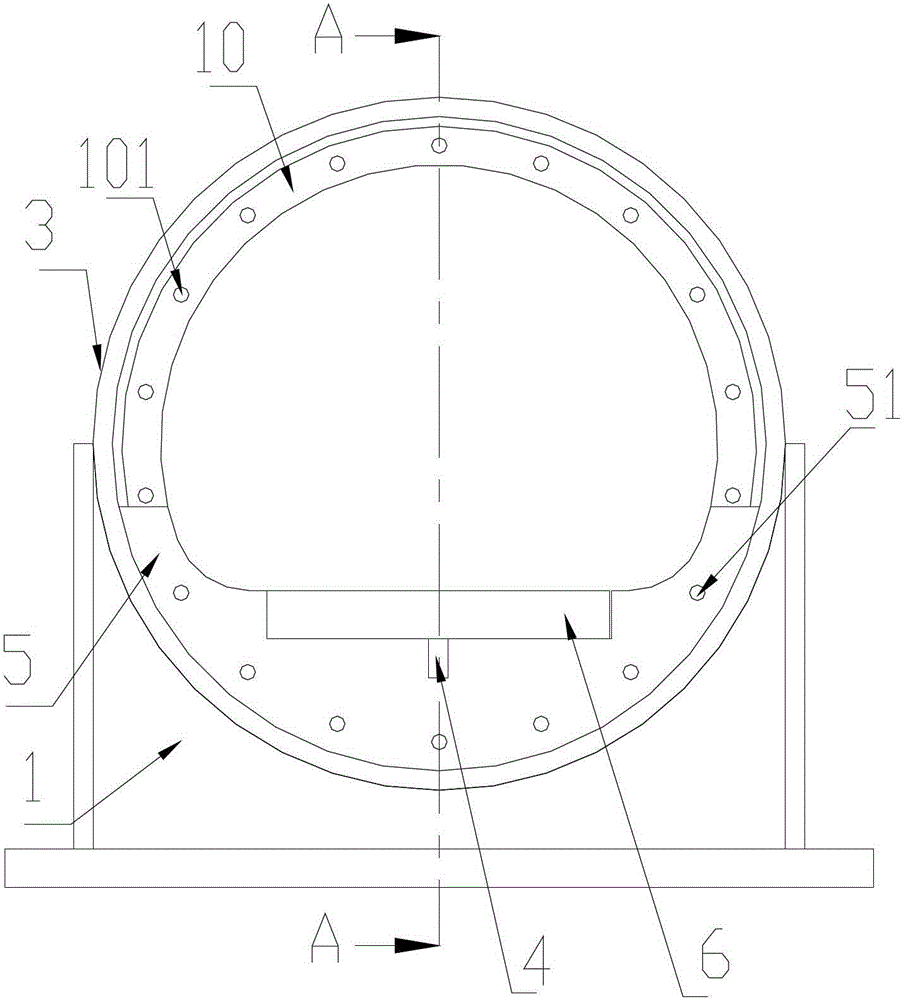

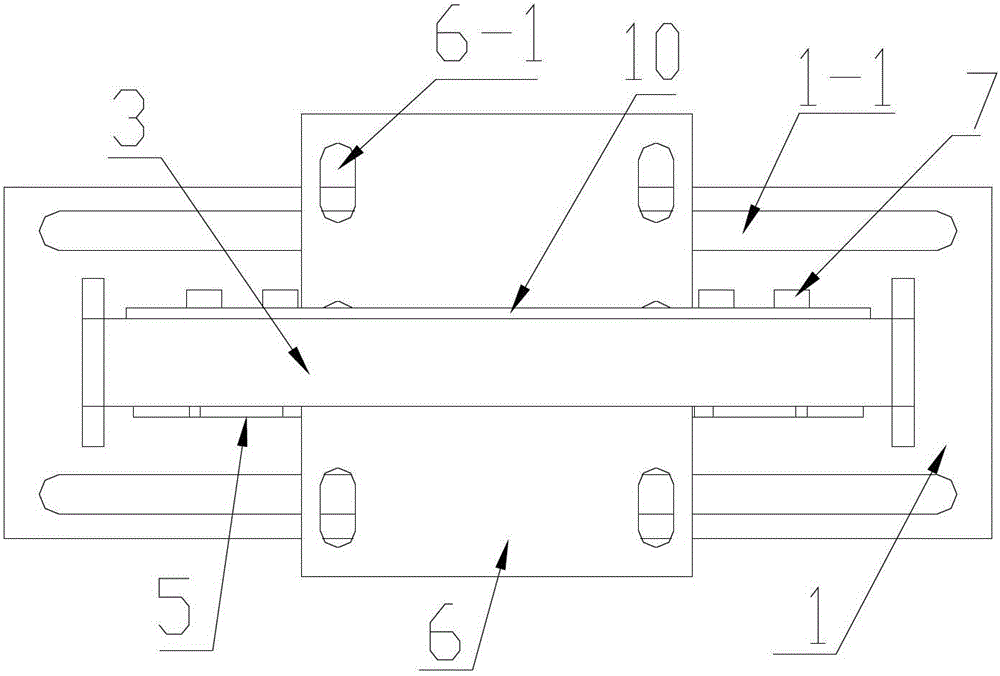

[0025] see figure 1 , figure 2 and Figure 4 , the present invention includes a fixed bracket, a fixed ring, a moving ring, a steering gear fixture fixing plate, and a moving circular arc plate, and is characterized in that: the front and rear sides of the fixed ring 3 are respectively provided with the front and rear of the fixed ring along the inner ring. , the rear groove; the front ring surface of the moving ring 10 is provided with a chute along the outer ring that fits the rear groove of the fixed ring; the moving circular arc plate 5 is a crescent-shaped plate with an arc bottom surface, and the moving circle Bolt holes 51 are evenly distributed on the surface of the arc plate 5 along the arc line. The rear side of the moving arc plate 5 is provided with a groove that fits the front groove of the fixed ring along the arc edge. The top surface of the moving arc plate 5 is embedded with a steering wheel. The fixing plate 6 of the machine fixture; the fixing ring 3 is ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com