Raschel machine

A warp knitting machine and tie rod technology, which is applied in warp knitting, textiles, papermaking, knitting, etc., can solve the problems of reducing the speed, increasing the running noise, and increasing the size of the guide bar-transmission rod and tie rod, etc., so as to avoid The effect of contact

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

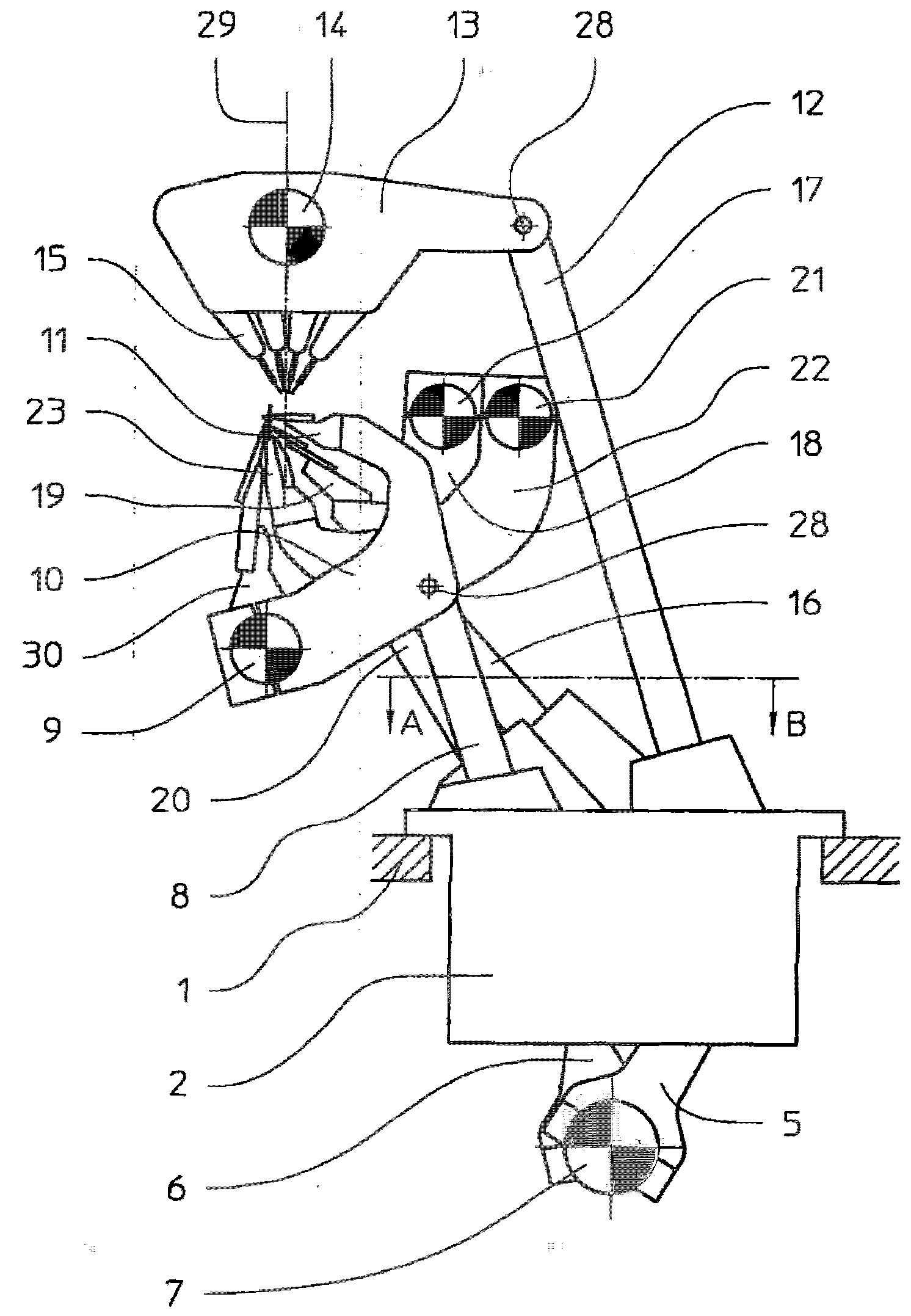

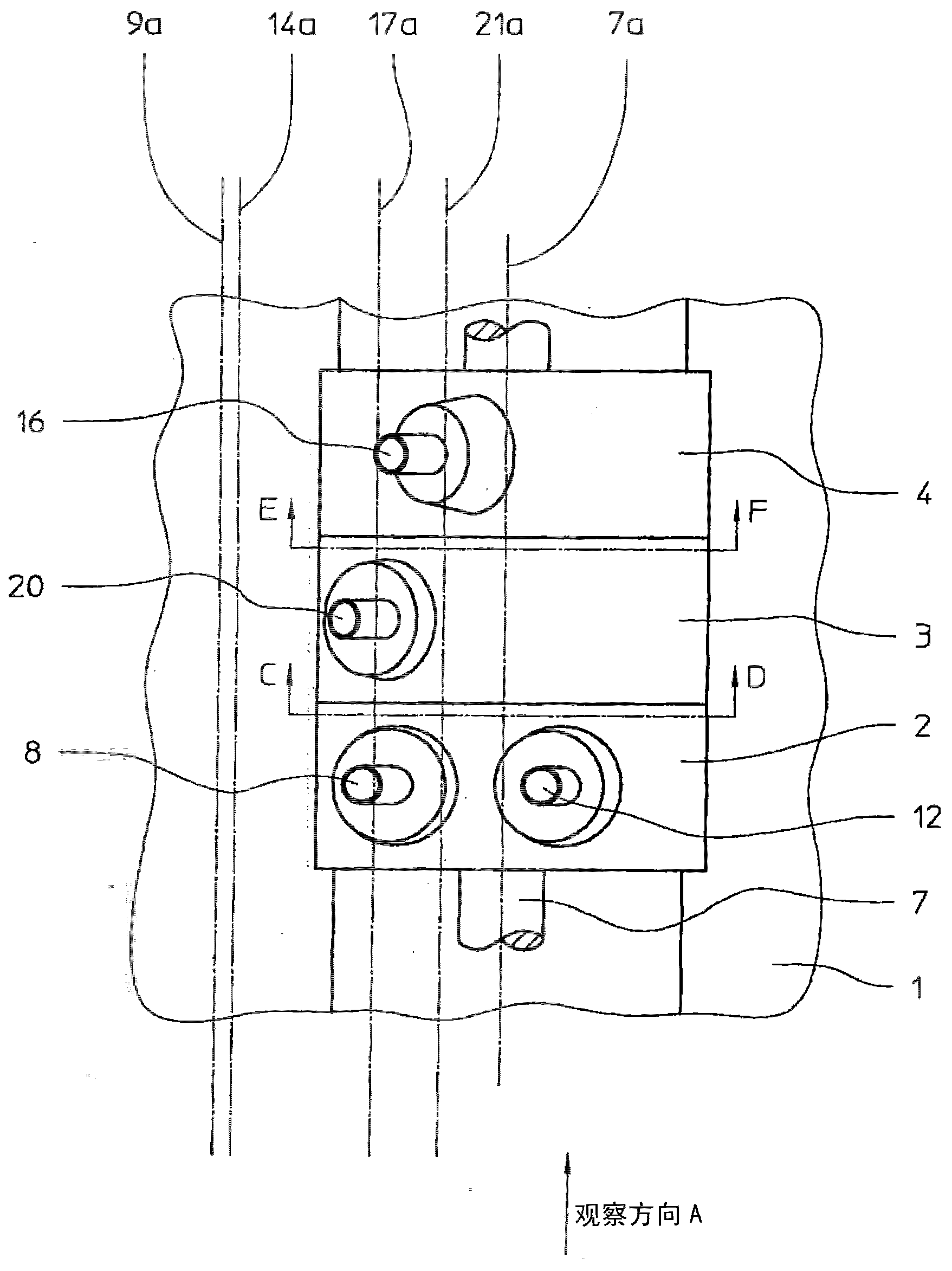

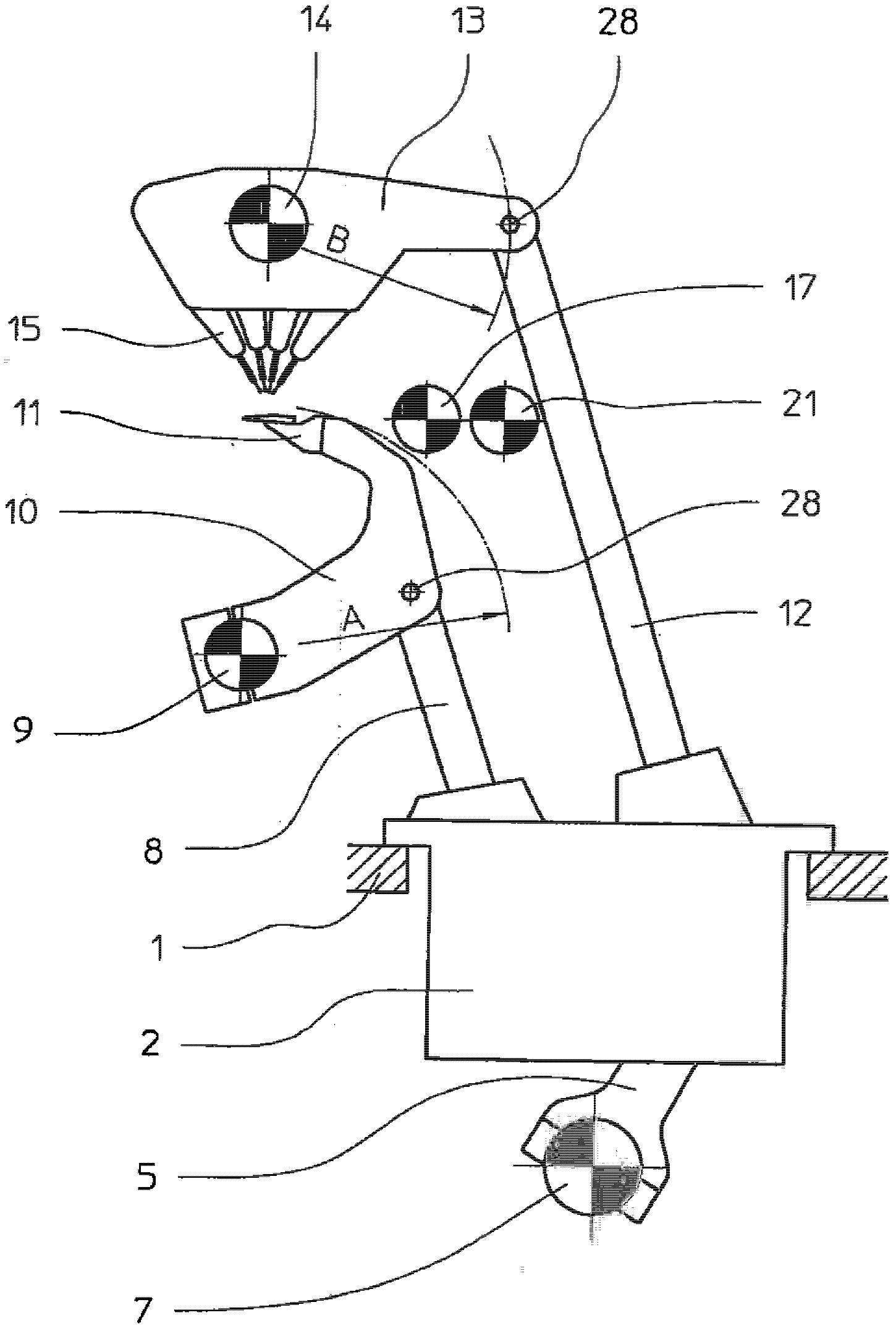

[0040] in the overview figure 1 and 2 shows that the drive of the raschel machine according to the invention has three drive units, which are essentially formed by three coupling groove drives (Koppelrastgetriebe) 2, 3 and 4. These drive units form the housing of the associated bayonet drive 2 , 3 and 4 . Via downwardly protruding connecting rods 5 and 6, the coupling drive gears 2, 3 and 4 are in drive connection with a crankshaft 7, which forms the drive shaft of the Raschel machine. The pull rods 8, 12, 16 and 20 protrude upwards from the coupling drive gear 2, 3 and 4, and these pull rods move the different comb bars 11, 15, 19 and twenty three. In addition, a drive joint 28 for force transmission is located between the coupling bay drives 2 , 3 and 4 and the tie rods 8 , 12 , 16 and 20 .

[0041] The drive unit can be a closed structural unit, which is fastened closely to one another on the machine tool 1 via the crankshaft 7, for which see figure 2 . However, the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com