An inner tub structure of a washing machine and a washing machine with the inner tub

A washing machine and inner tub technology, applied in the field of washing machines, achieves the effects of low installation cost and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

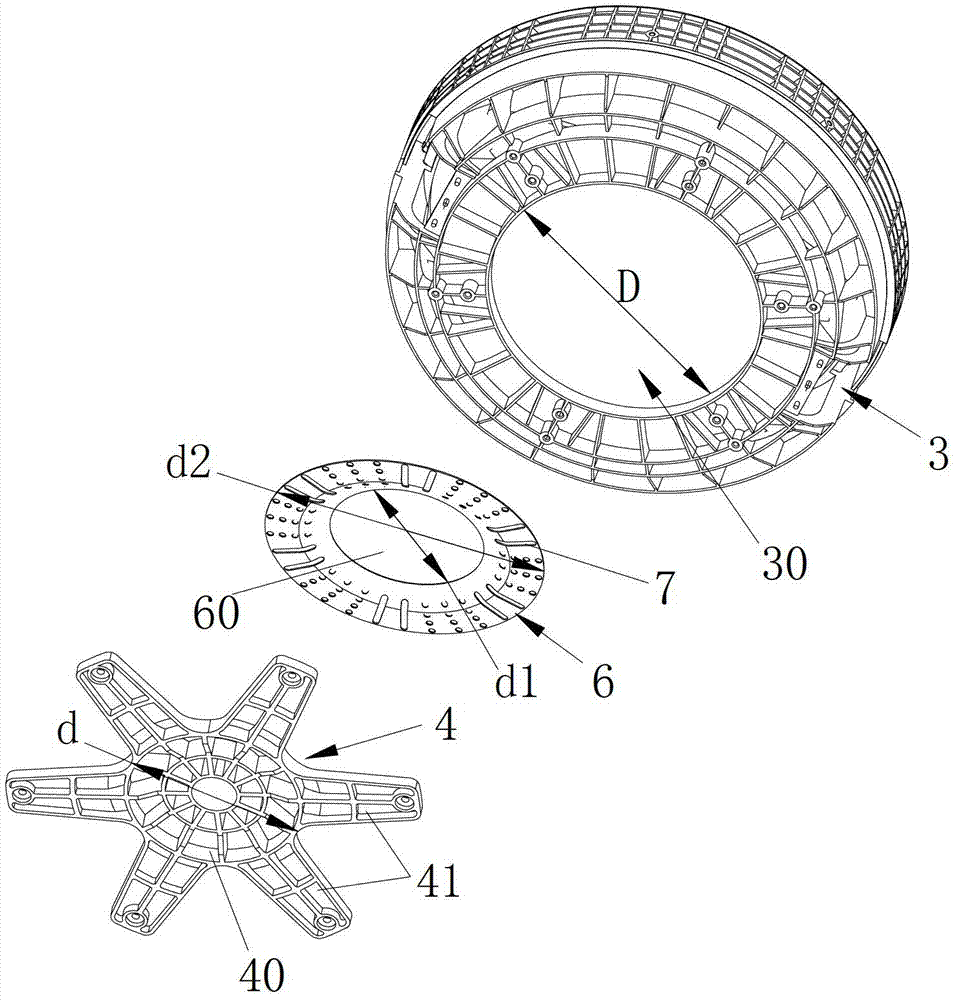

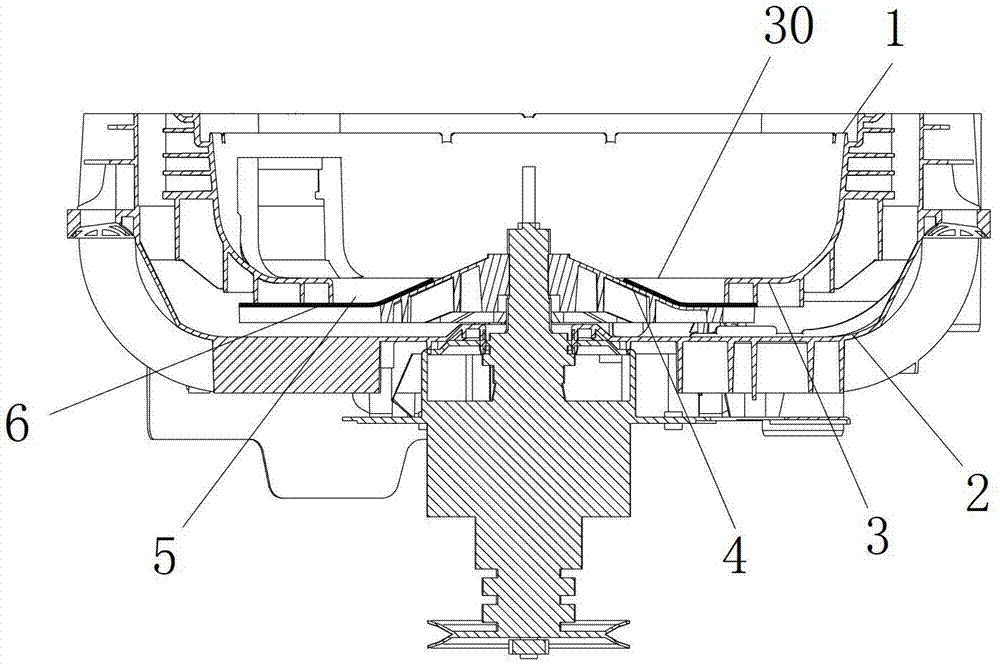

[0037] There are at least two types of the blocking cover, the flange plate and the bottom of the inner bucket described in the present invention which are integrally injection molded. The blocking cover 6 described in this embodiment is integrally injection-molded with the bottom 3 of the inner barrel, that is, d1≤d

Embodiment 2

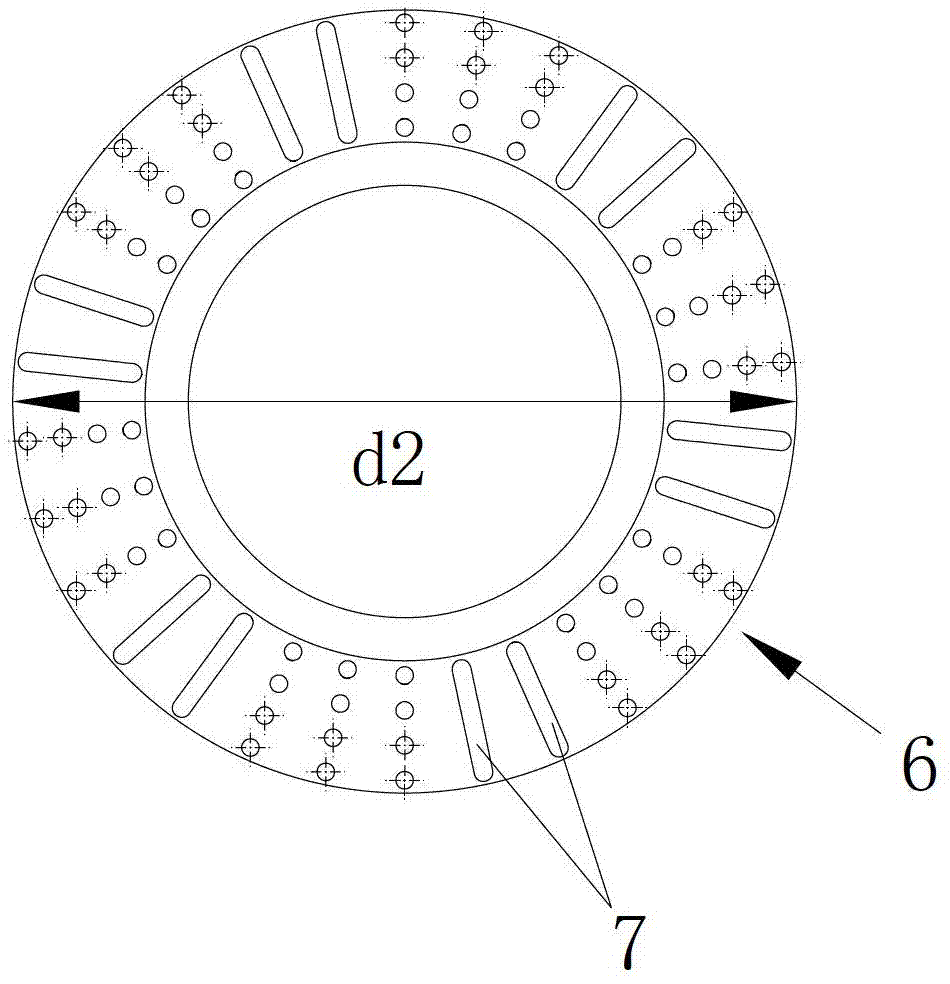

[0039] The difference between this embodiment and Embodiment 1 is that the blocking cover 6 is an independent cover body structure, the outer diameter d2 of the blocking cover is the same as the inner diameter D of the hollow area at the bottom of the inner barrel, and the blocking cover 6 is fitted and bonded to the bottom of the inner barrel and is hollow In area 30, such as image 3 As shown, the inner diameter d1 of the blocking cover 6 is smaller than the diameter d of the main body 40 of the flange, that is, the blocking cover 6 has a part of the annular cover overlapping with the main body 40 of the flange, and the permeable holes 7 are distributed outside the annular cover that does not overlap with the main body 40 The area corresponds to the space between two adjacent fixing feet 41 of the flange 4 . or, as in Figure 5 As shown, the buckle structure corresponding to the outside of the hollow area 30 at the bottom of the inner tub is buckled by the snapping structur...

Embodiment 3

[0041]The barrier cover 6 described in this embodiment is an independent cover body structure, the outer diameter d2 of the barrier cover is larger than the inner diameter D of the hollow area 30 at the bottom of the inner barrel, and is sandwiched between the flange plate 4 and the inner barrel by the flange plate fixing feet 41 Between bottom 3, satisfy d1≤d Figure 4 As shown, the inner diameter d1 of the blocking cover 6 in this embodiment may be equal to the diameter d of the flange main body 40 , and the water permeable hole 7 is arranged in the area between the two adjacent fixing feet 41 of the blocking cover 6 corresponding to the flange 4 .

[0042] Preferably, the blocking cover described in this embodiment is installed on the bottom of the inner tub, and then sandwiched between the flange and the bottom of the inner tub by means of a flange.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com