Gypsum powder continuous calcining device

A calcining device and gypsum powder technology are applied in the field of gypsum powder production, which can solve the problems of large dust, affect the calcination of gypsum powder, reduce the filter effect of cloth bags, etc., and achieve the effects of ensuring dust reduction efficiency, production efficiency, and calcination efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

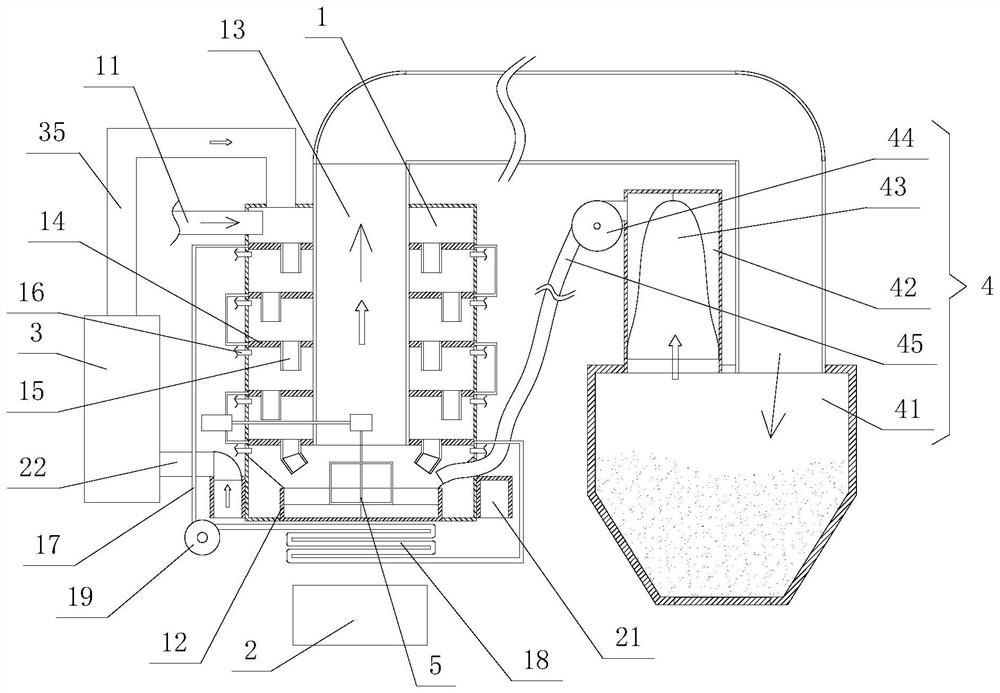

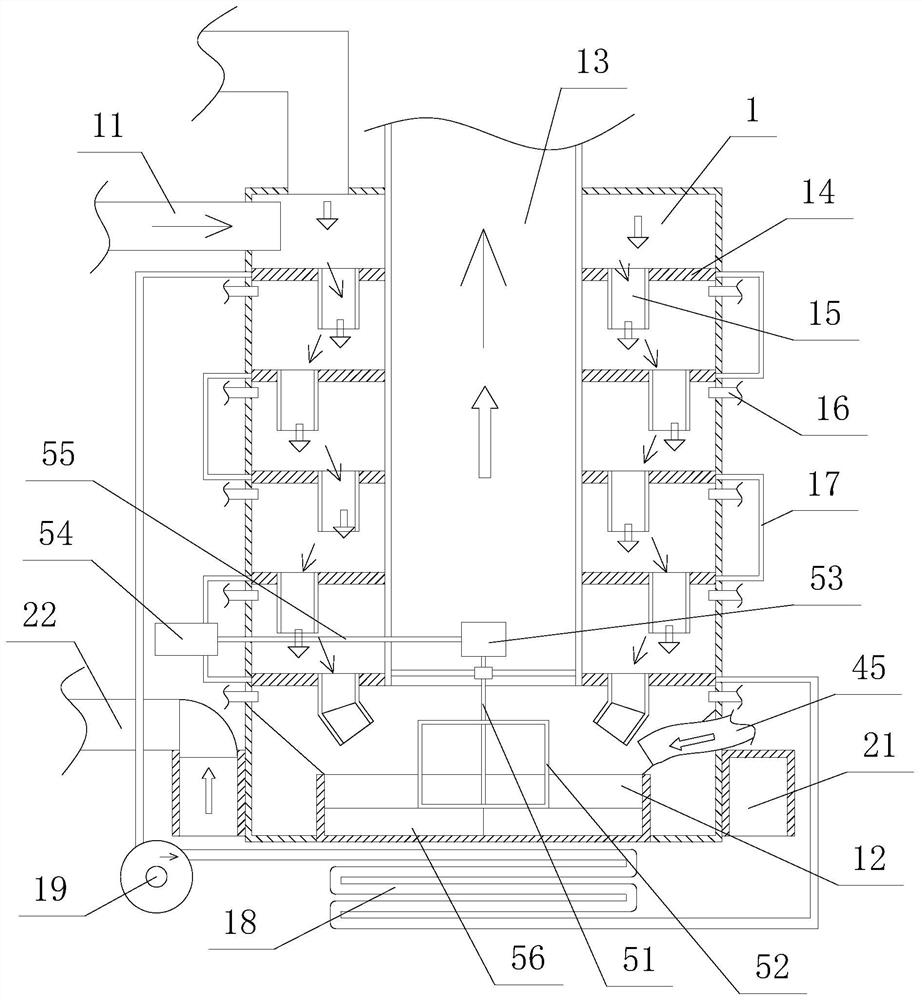

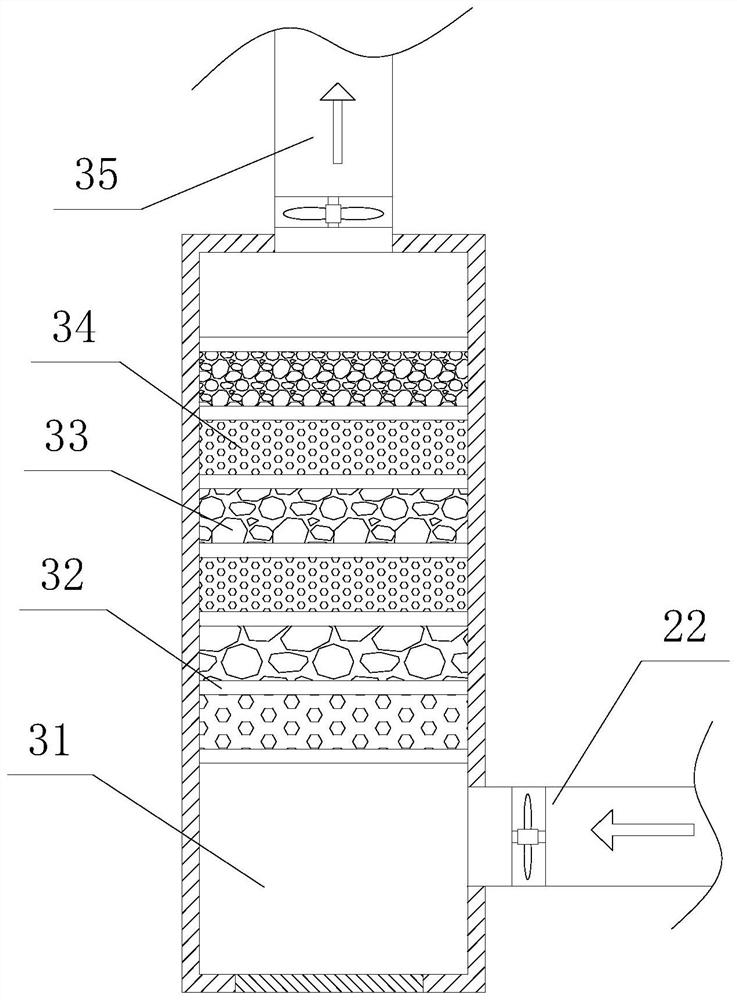

[0023] figure 1 It is a schematic structural diagram provided by an embodiment of the present invention, figure 2 A schematic diagram of the internal structure of the calcining cylinder provided in the embodiment of the present invention, image 3 It is a schematic diagram of the internal structure of the filter provided by the embodiment of the present invention, wherein the hollow arrow is the flow direction of the air, and the solid arrow is the flow direction of the gypsum powder. The continuous calcining device for the gypsum powder provided in this embodiment includes a calcining cylinder 1, a burner 2, and a filter 3. and the dust suppression device 4, the calcining cylinder 1 is vertically arranged, a receiving tray 12 is installed at the bottom of the calcining cylinder 1, and a guide cylinder 13 is set inside the calcining cylinder 1 above the receiving tray 12. The guide cylinder 13 and the calcining cylinder 1 A multi-layer preheating plate 14 is installed betwee...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com