Running-in and debugging bench for motorcycle engine

An engine and motorcycle technology, applied in the field of benches, can solve the problems of high labor intensity, low production efficiency, and is not suitable for small-scale enterprises, and achieve the effects of fast loading and disassembly, reducing labor intensity and improving production efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

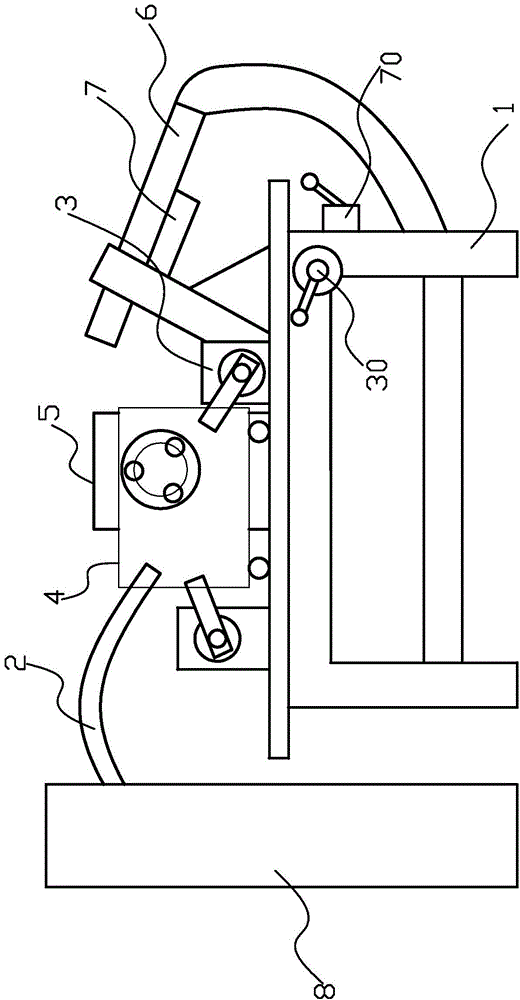

[0011] refer to figure 1 , a running-in debugging stand for a motorcycle engine, comprising a stand main body 1, a clamping mechanism 3 for clamping the engine 4 is arranged on the top of the stand main body 1, the number of the above-mentioned clamping mechanisms 3 is two, and they are respectively arranged on On the left and right sides of the engine 4, one side of the engine 4 is provided with an exhaust system 6 detachably connected with it, and the other side of the engine 4 is provided with a debugging electric cabinet 8 for running in the engine 4, and the debugging electric cabinet 8 is provided with a The ignition coil 2 for the ignition of the engine 4, the clamping mechanism 3 is driven by a cylinder or a hydraulic cylinder, and the exhaust system 6 is provided with an exhaust connection drive device 7 that drives it to automatically connect with the engine 4. The above-mentioned exhaust connection drives The device 7 is preferably arranged at the bottom of the exha...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com