Mechanical intelligent self-adaptation automatic clutch

An automatic clutch and self-adaptive technology, applied in automatic clutches, clutches, one-way clutches, etc., to achieve the effects of improving safety, eliminating jamming, and ensuring sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

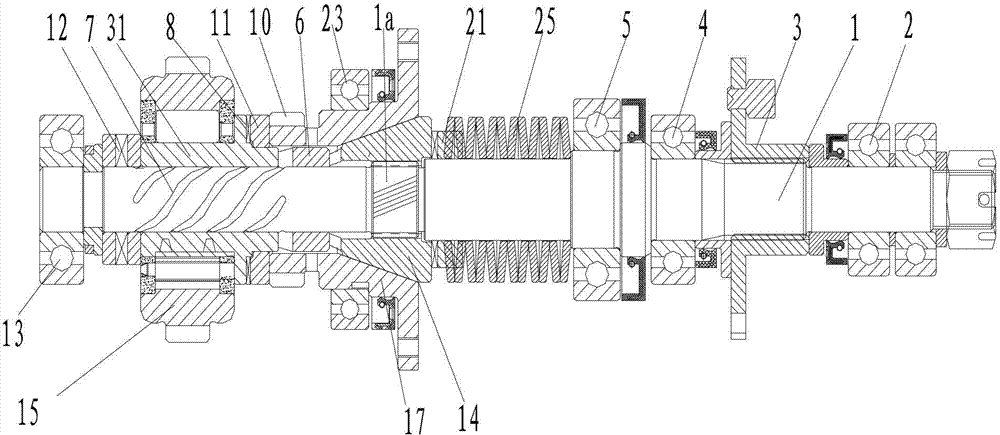

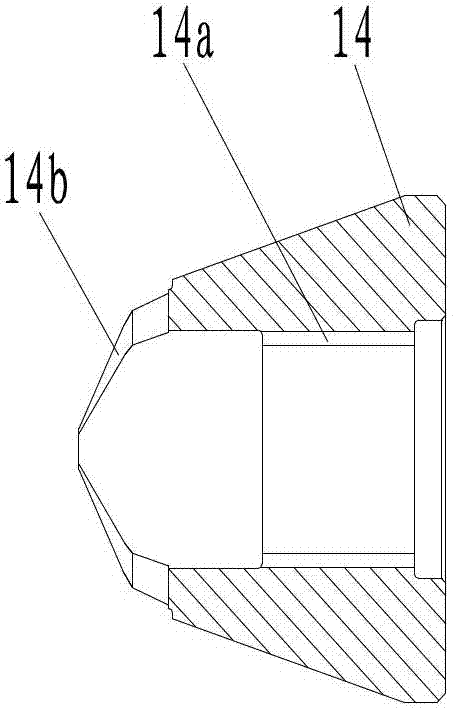

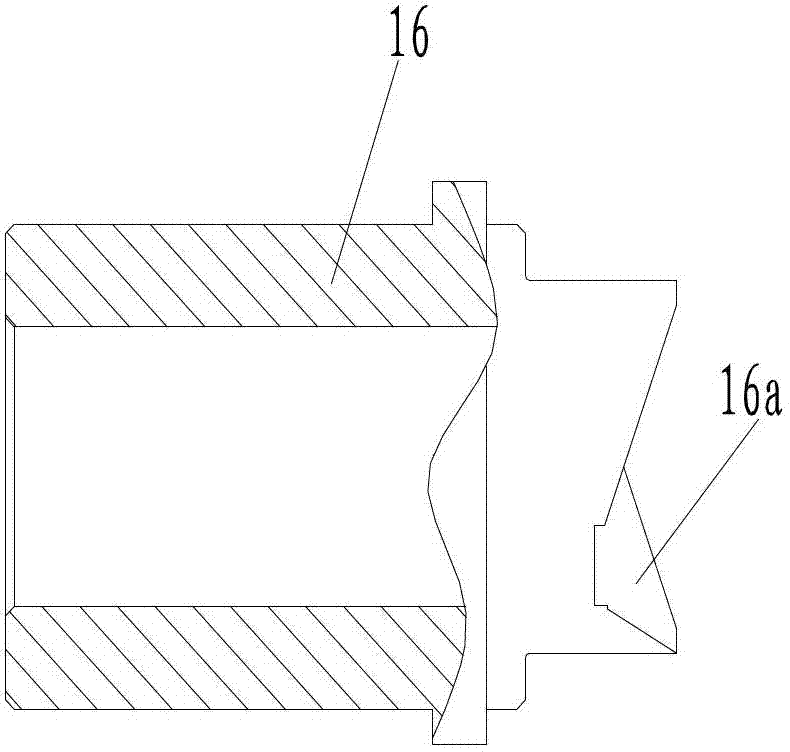

[0033] figure 1 It is a schematic diagram of the axial section structure of the present invention, figure 2 It is a schematic diagram of the structure of the axial outer taper sleeve of the torus, image 3 It is a structural schematic diagram of the inner ring of the overrunning clutch, Figure 4 Schematic diagram of the oil passage structure on the tapered surface of the axial outer tapered sleeve of the annular body; Figure 5 It is a structural schematic diagram of the middle cam sleeve; Figure 6 It is a schematic diagram of cam expansion at both ends of the middle cam sleeve; Figure 7 Schematic diagram of the structure of the overrunning clutch; Figure 8 It is a schematic diagram of the support column, the support piece and the reed, Figure 9 It is a schematic diagram of the reed structure, Figure 10 It is a schematic diagram of an axial partial sectional structure of an overrunning clutch, as shown in the figure: the mechanically intelligent adaptive automatic...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap