Lens module

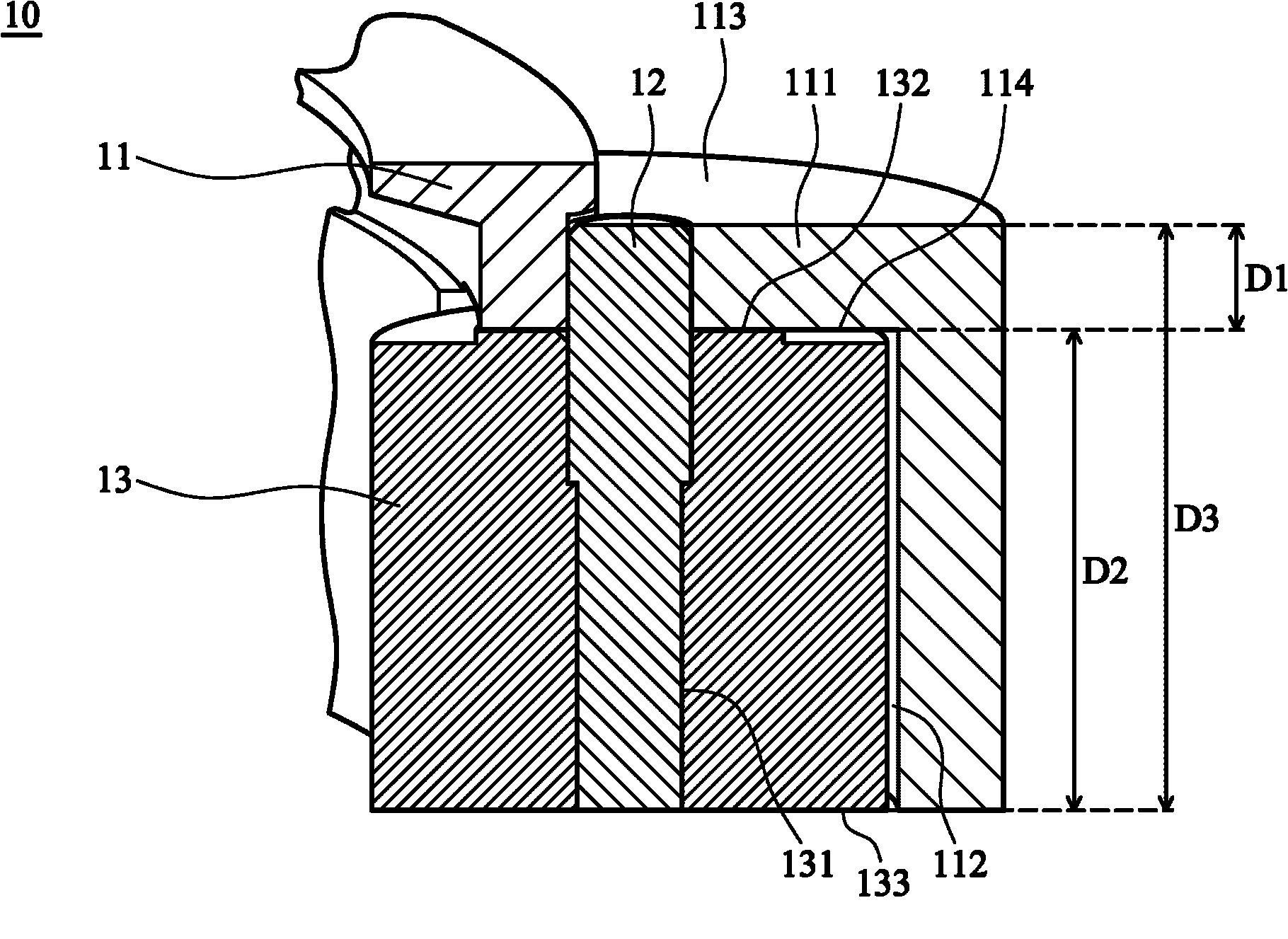

A technique for lens modules and recessed parts, applied in the directions of installation, optics, instruments, etc., can solve problems such as the inability to achieve the goal of being thin and light, and the thickness of the lens module 10 is limited, and achieve the effect of reducing the overall height and volume.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

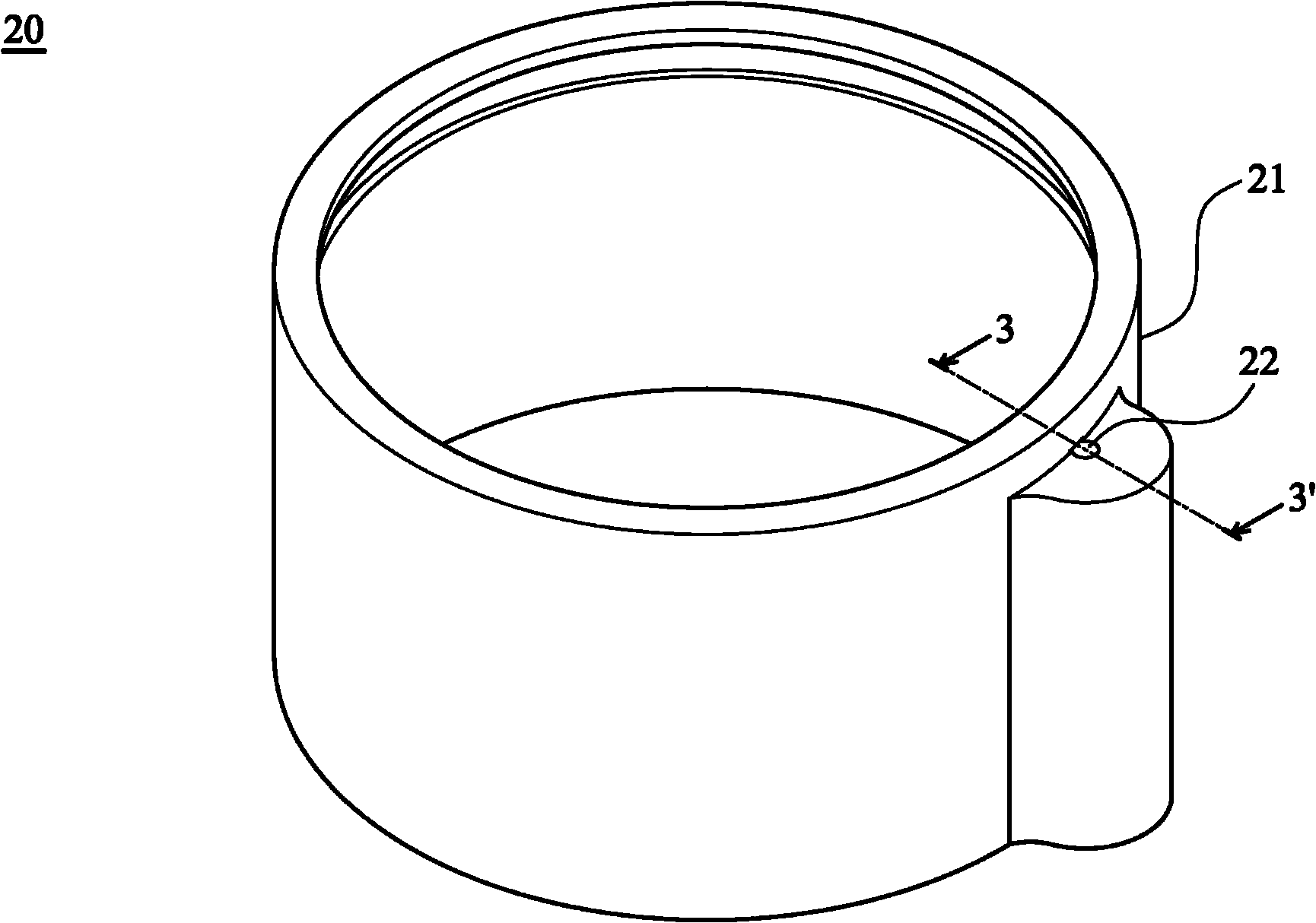

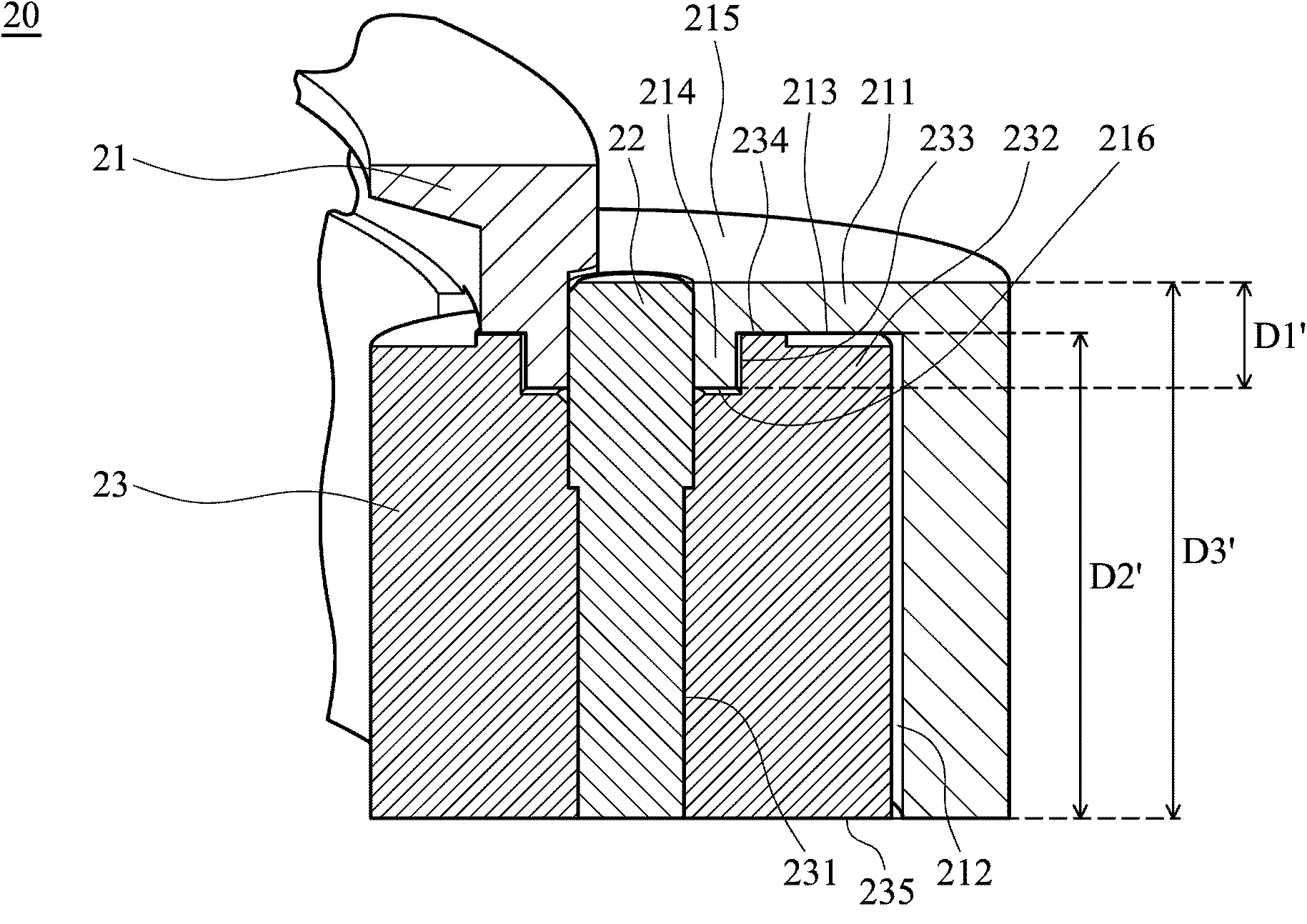

[0015] figure 2 It is a schematic diagram of a lens module according to an embodiment of the present invention. image 3 for along figure 2 The schematic cross-section of the line 3-3'.

[0016] see figure 2 , 3 The lens module 20 includes a fixed cylinder 21, a guide shaft 22, and a long tooth portion 23. The fixed cylinder 21 includes a housing 211, an accommodating groove 212, a first concave portion 213, and a first relative protruding portion 214. The housing 211 forms an accommodating The groove 212 includes an upper surface 215 and an inner surface 216 . In this embodiment, the first concave portion 213 and the first relative protruding portion 214 are arranged adjacent to each other.

[0017] The guide shaft 22 extends from the upper surface 215 of the housing 211 to the accommodating groove 212, and is located in the accommodating groove 212. The long tooth portion 23 includes a positioning groove 231, a second relative protruding portion 232, a second concave ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com