Variable-stage or variable-cylinder variable displacement compressor and control method thereof

A compressor and variable displacement technology, which is applied in the field of compressors, can solve the problems of not being able to pull, increase the power consumption of the top slide, and restrict the application and development of frequency conversion technology, so as to achieve the goal of increasing the high-temperature cooling capacity and improving the advantages of heating capacity Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

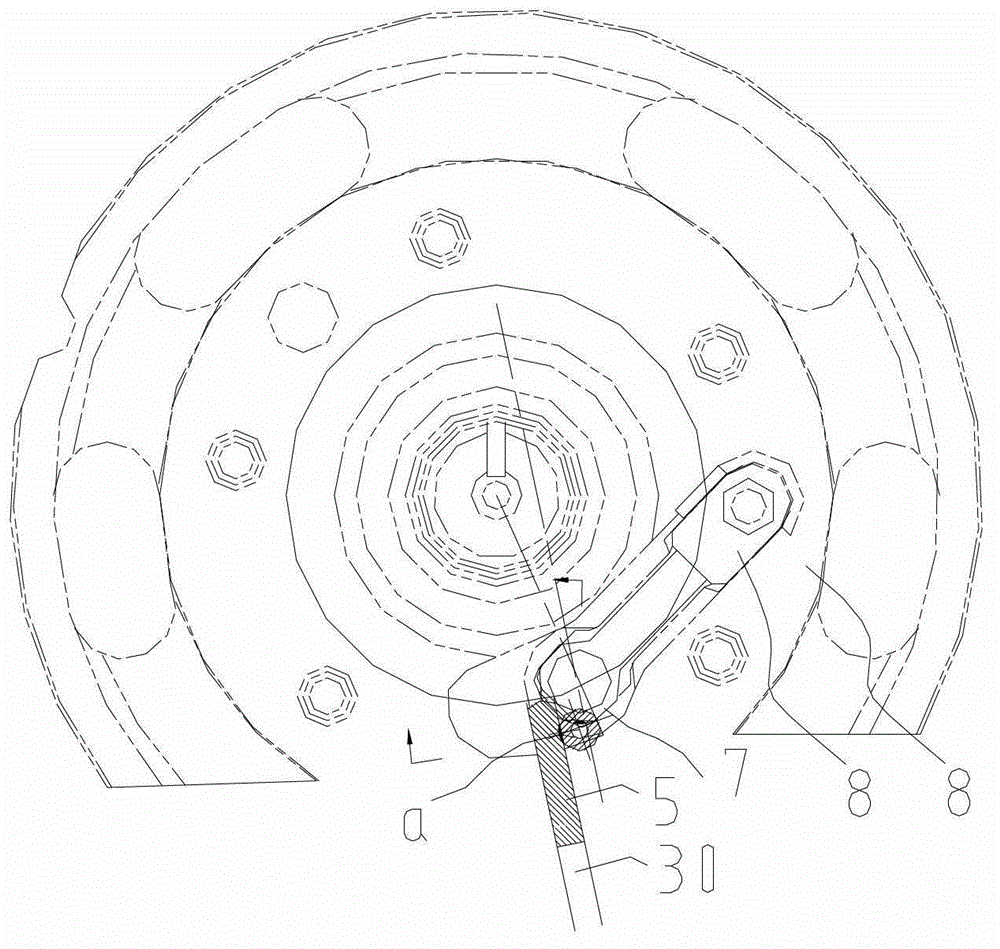

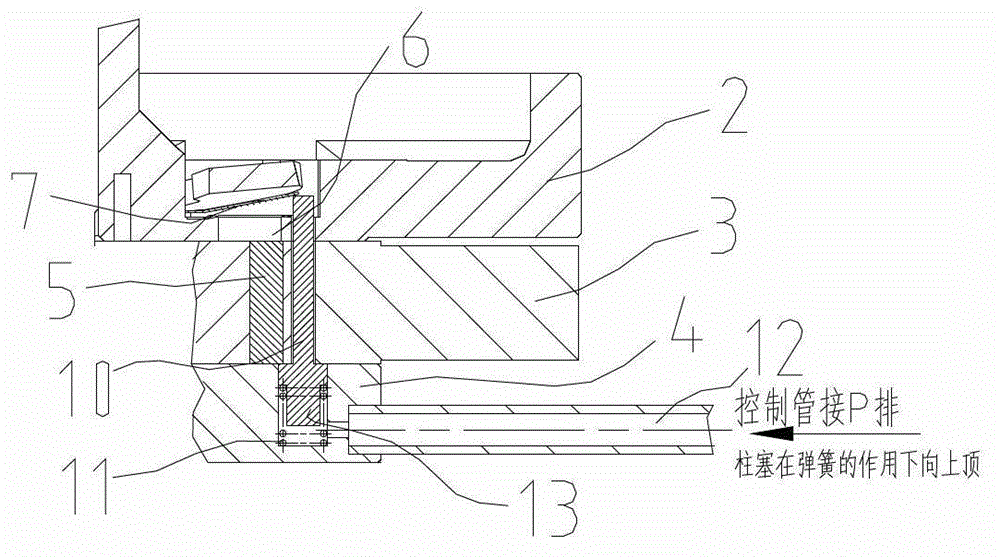

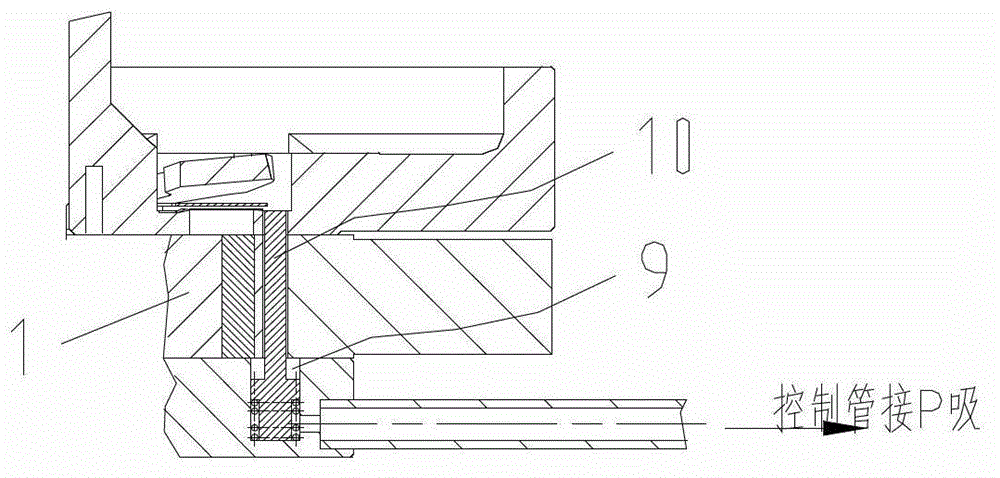

[0021] A variable-stage or variable-cylinder variable-displacement compressor, such as Figure 1 to Figure 3 As shown, it includes crankshaft (not shown in the figure), upper roller 1, lower roller (not shown in the figure), upper flange 2, upper cylinder 3, separator 4, lower cylinder (not shown in the figure) and lower Flange (not shown in the figure), the upper and lower rollers are respectively installed on the crankshaft and rotate in the upper and lower cylinder chambers, the cylinder wall of the upper cylinder 3 is provided with a sliding vane groove 30, and the sliding vane groove 30 is equipped with The upper slide 5 that works in cooperation with the upper roller 1; the upper flange 2 is provided with an exhaust hole 6 communicating with the compression working chamber of the upper cylinder 3, and the upper flange 2 is equipped with a plug to block the exhaust hole 6 The valve plate 7 and the baffle plate 8 are provided with a plunger hole 9 on the axial direction of...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com