Insulator breakage fault detection method based on second-generation curvelet coefficient morphology band energy method

A technology of curvelet coefficient and insulator, which is applied in the field of insulator damage fault detection based on the second-generation curvelet coefficient morphology strip energy method, which can solve the problems of complex images and achieve high accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

[0070] In order to verify the effectiveness of the insulator fracture fault identification algorithm based on the second-generation curve wave morphological closed operation energy strip method, the fault map and non-fault map taken under different conditions in the collection gallery were tested for recognition.

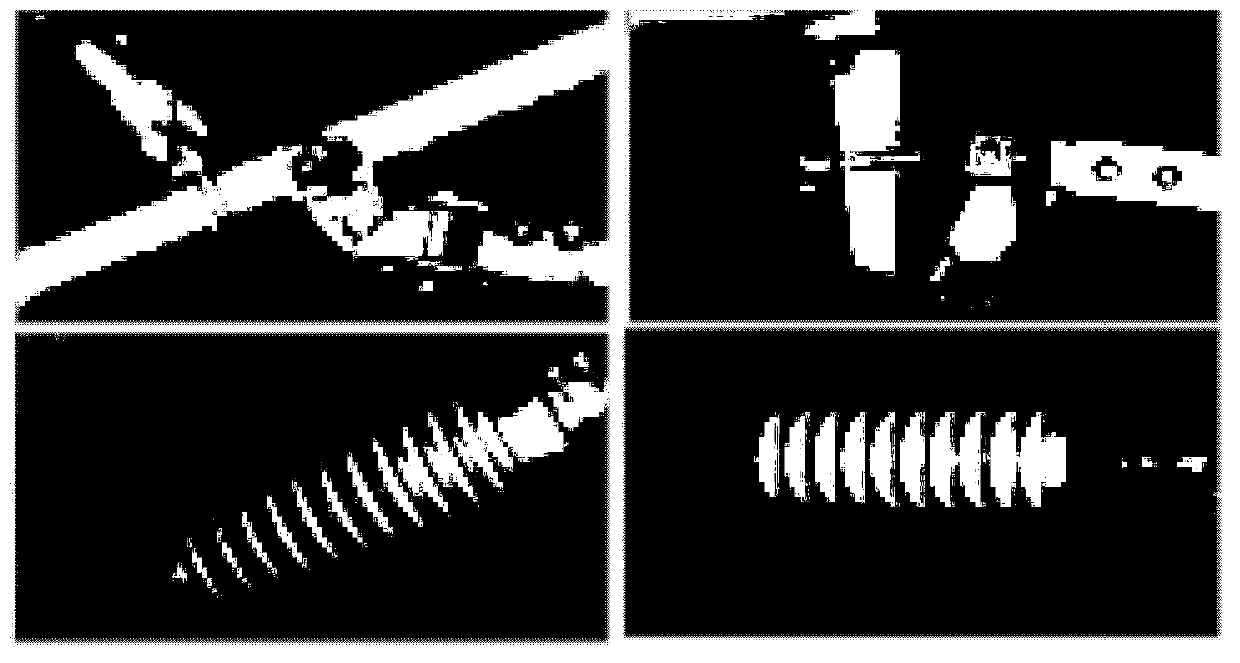

[0071] Fault 1: If Figure 9 , a piece is missing at the left edge of the insulator. The test results are shown in Figure 10, where:

[0072] Figure a image preprocessing results

[0073] Figure b is the result of curvelet directional filtering;

[0074] Figure c is the result of direction morphology closing operation;

[0075] Figure d shows the energy distribution of the strip.

[0076] It can be clearly seen from the figure that the position where the curve wave coefficient should have a uniform distribution is missing, and it can be clearly judged that the insulator is damaged at this position.

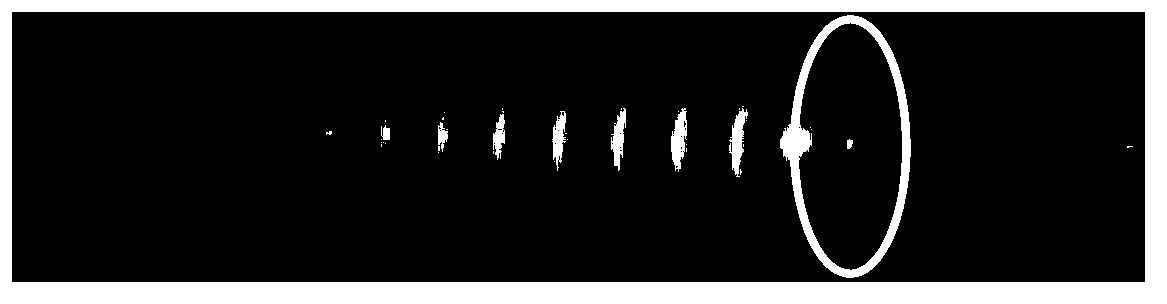

[0077] Fault 2: If Figure 11 , a piece is missing in the mi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com