Articulation type robot

A robot and joint-type technology, applied in manipulators, manufacturing tools, etc., can solve problems such as inability to use cooling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 1 approach

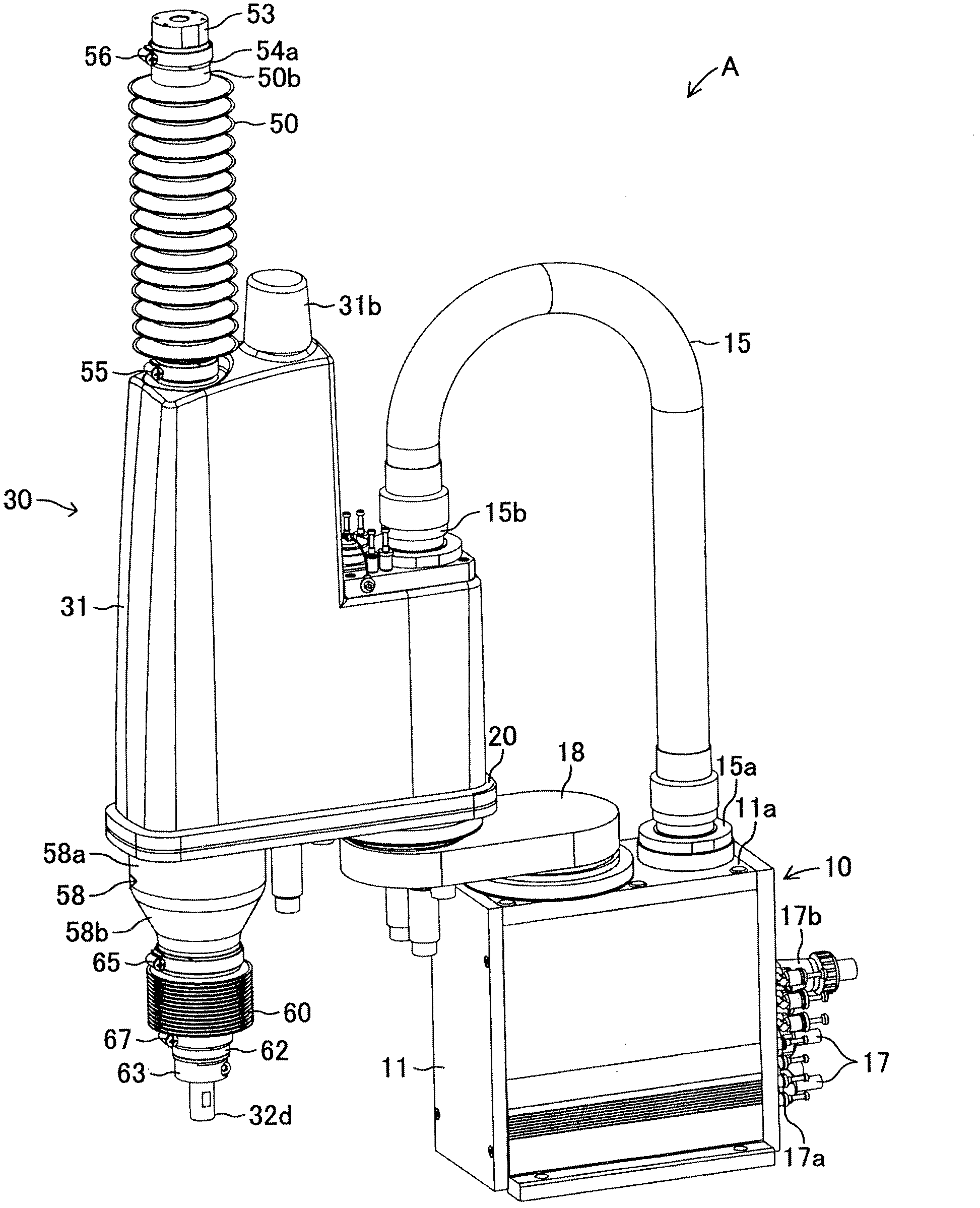

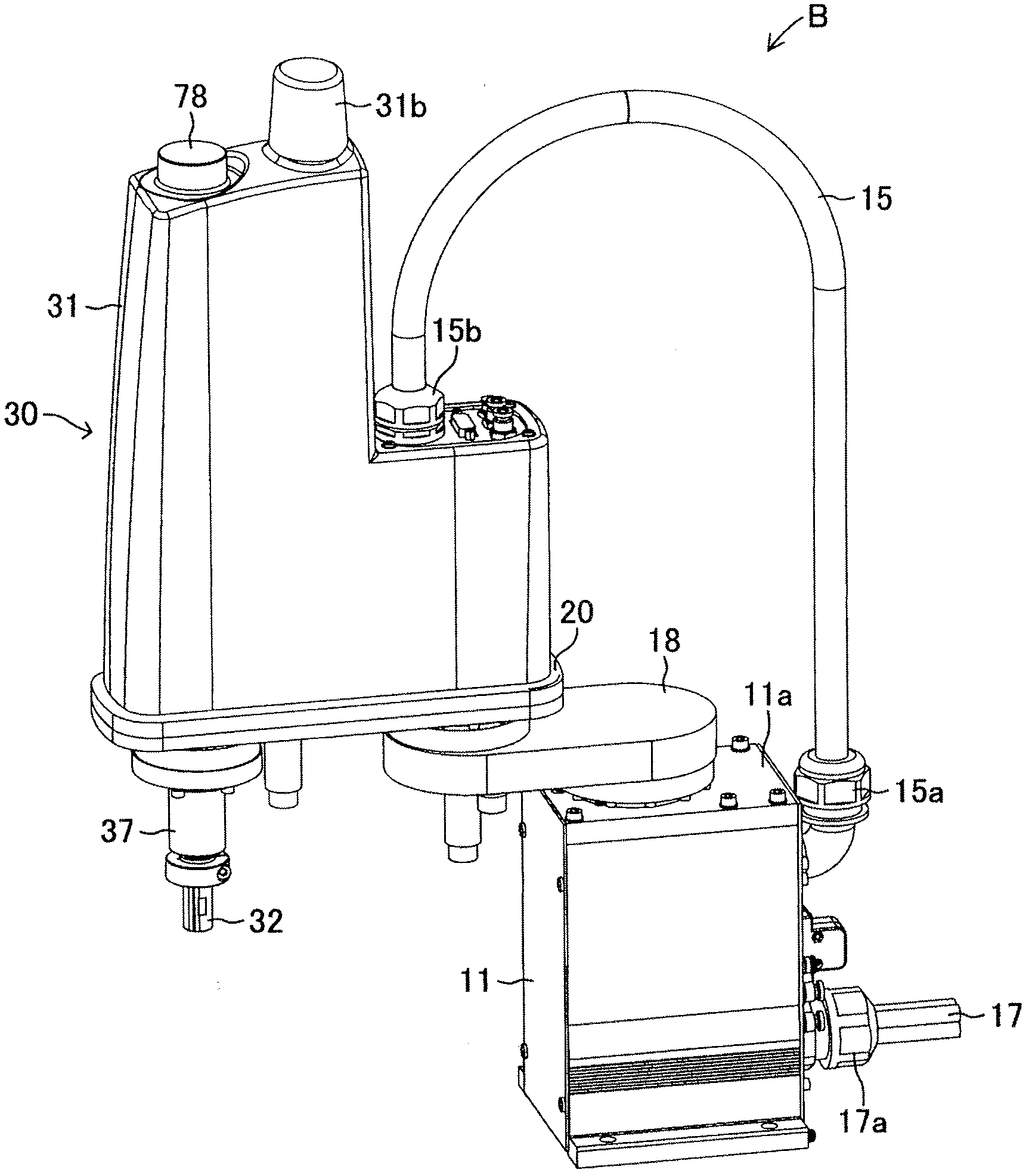

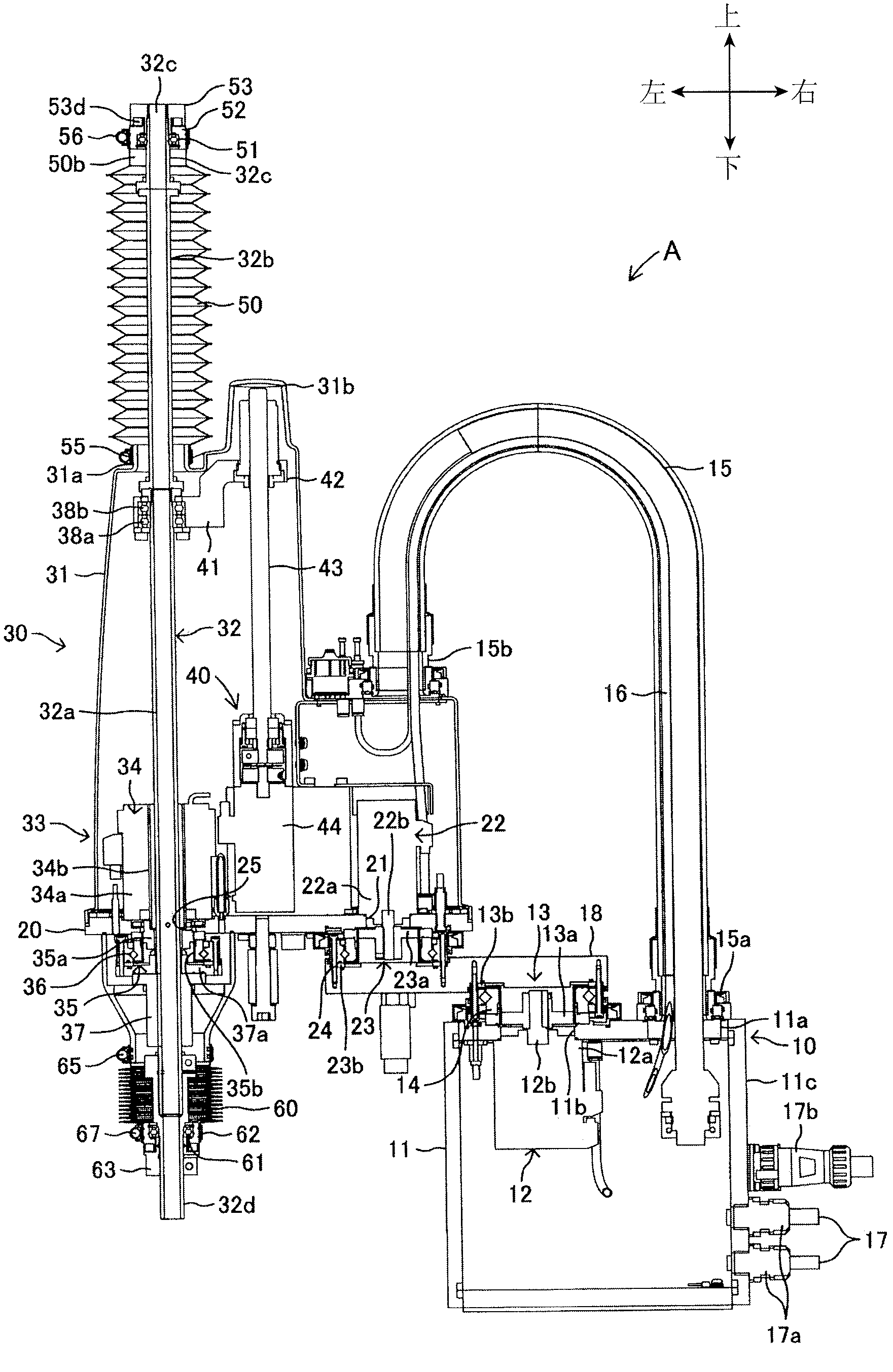

[0024] The articulated robot according to the first embodiment of the present invention will be described below based on the drawings. figure 1 The articulated robot A according to the first embodiment is shown. This articulated robot A includes a base 10 , a first arm 18 , a second arm 20 (arm), an elevating and rotating drive device 30 provided on the second arm 20 , and upper bellows-shaped members provided above and below the elevating and rotating drive device 30 . 50 and the lower bellows part 60. The articulated robot A is, for example, in figure 2 The articulated robot B of the standard specification shown is an articulated robot in which an upper accordion-shaped member 50 and a lower accordion-shaped member 60 are provided to form a dust-proof and drip-proof specification with some modifications added.

[0025] The base 10 is fixedly installed on a floor, a table or the like. Such as image 3 as well as Figure 4 As shown, the base 10 includes: a rectangular bo...

no. 2 approach

[0073] Figure 12 and Figure 13 An articulated robot C according to a second embodiment of the present invention is shown. This articulated robot C is an articulated robot in which the layout of the wiring and piping 70 (hereinafter referred to as wiring and the like 70 ) connected to the wiring and the like 16 extending through the flexible tube 15 in the above-mentioned articulated robot A is changed, Parts other than the mounting structure of the wiring etc. 70 are the same as those of the articulated robot A. Therefore, the same reference numerals will be attached to the same parts for description.

[0074] In this articulated robot C, the wires and the like 70 extend from the lower right side portion of the upper surface of the cover 31 to the upper end of the connecting shaft 32c. The base end portion of the wiring etc. 70 is fixed by a connection member 71 provided on the upper surface of the cover 31 including a wiring connector and a pipe fitting. Proximal end po...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com