Integrated hot runner assembly process

An assembly process and hot runner technology, applied in the field of integral hot runner assembly process, can solve problems such as poor products and imperfect processes, and achieve the effect of long service life, outstanding substantive characteristics and longer service life.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

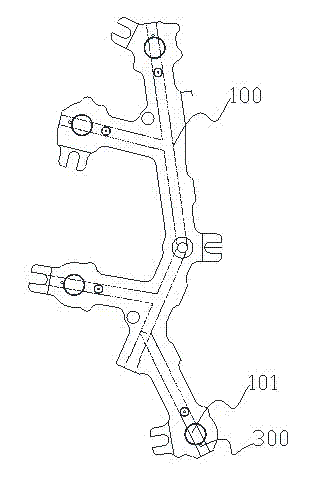

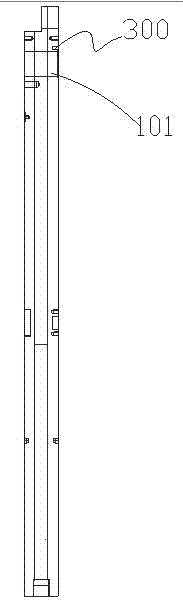

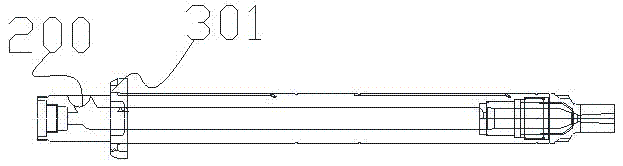

[0017] combine Figure 1 to Figure 3 , which describes the specific implementation of the present invention in detail, but does not limit the claims in any way.

[0018] An integral hot runner assembly process of the present invention includes a diverter plate 100, and a plurality of diverter holes 101 are arranged on the diverter plate 100, and the size of the diverter holes 101 is equal to or slightly smaller than the hot nozzle 200; The hole 101 is circular, and correspondingly, the hot nozzle 200 is also circular, and the inner diameter of the distribution hole 101 is slightly smaller than the outer diameter of the hot nozzle 200; Thermal expansion, insert the hot nozzle 200 into the distribution hole 101 of the distribution plate 100 . During implementation, the temperature of the splitter plate can be adjusted at a temperature above 100°C according to actual needs. During implementation, a guide hole 300 is provided on one side of the diversion hole 101, and a guide gr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com