Variable geometry turbocharger

A turbocharger and capacity technology, applied in the direction of machines/engines, engine components, internal combustion piston engines, etc., can solve the problems of turbine efficiency reduction, exhaust gas disorder, etc., and achieve the effect of stable operation and simple structure

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

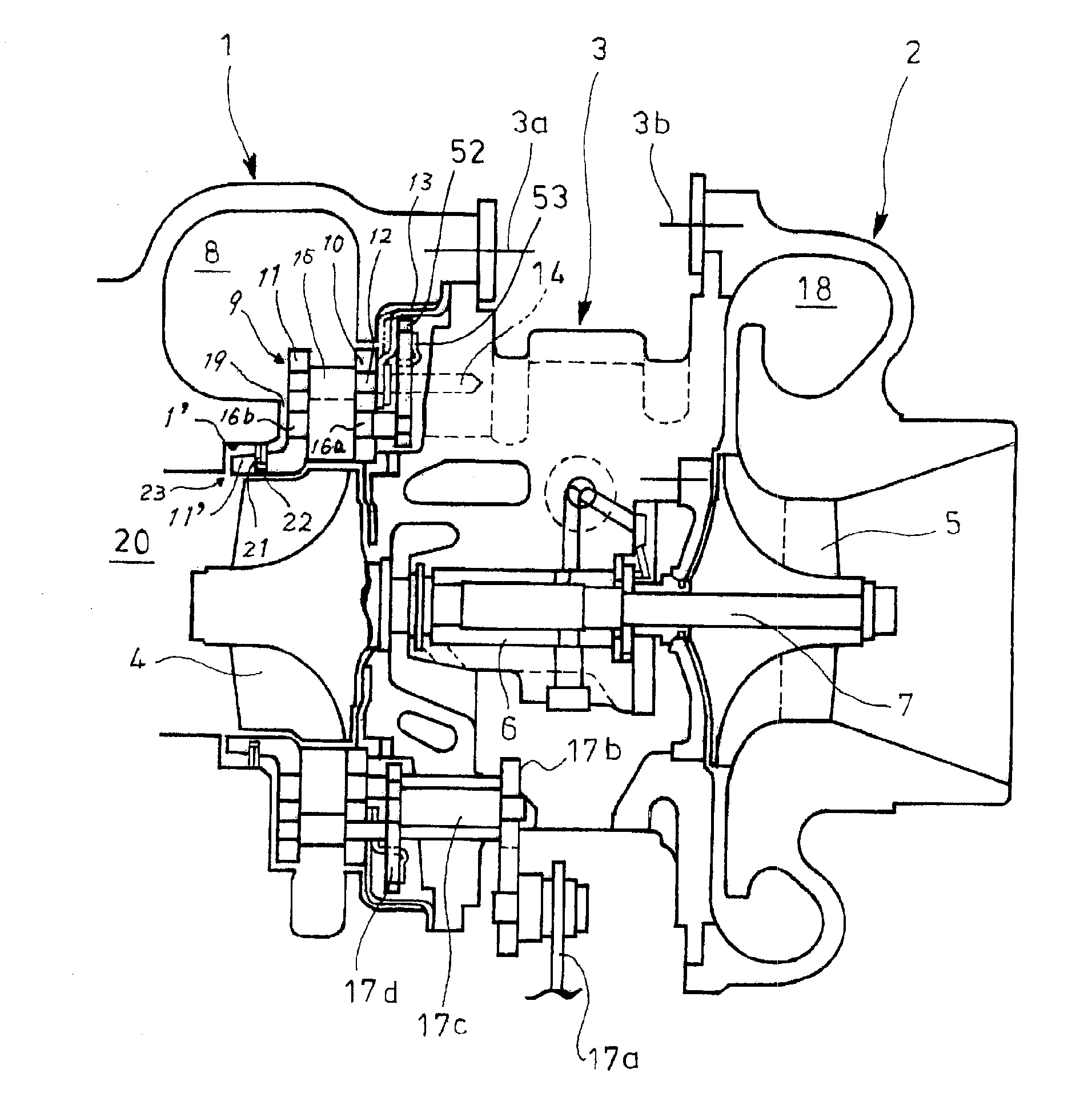

[0037] Hereinafter, embodiments of the present invention will be described with reference to the drawings.

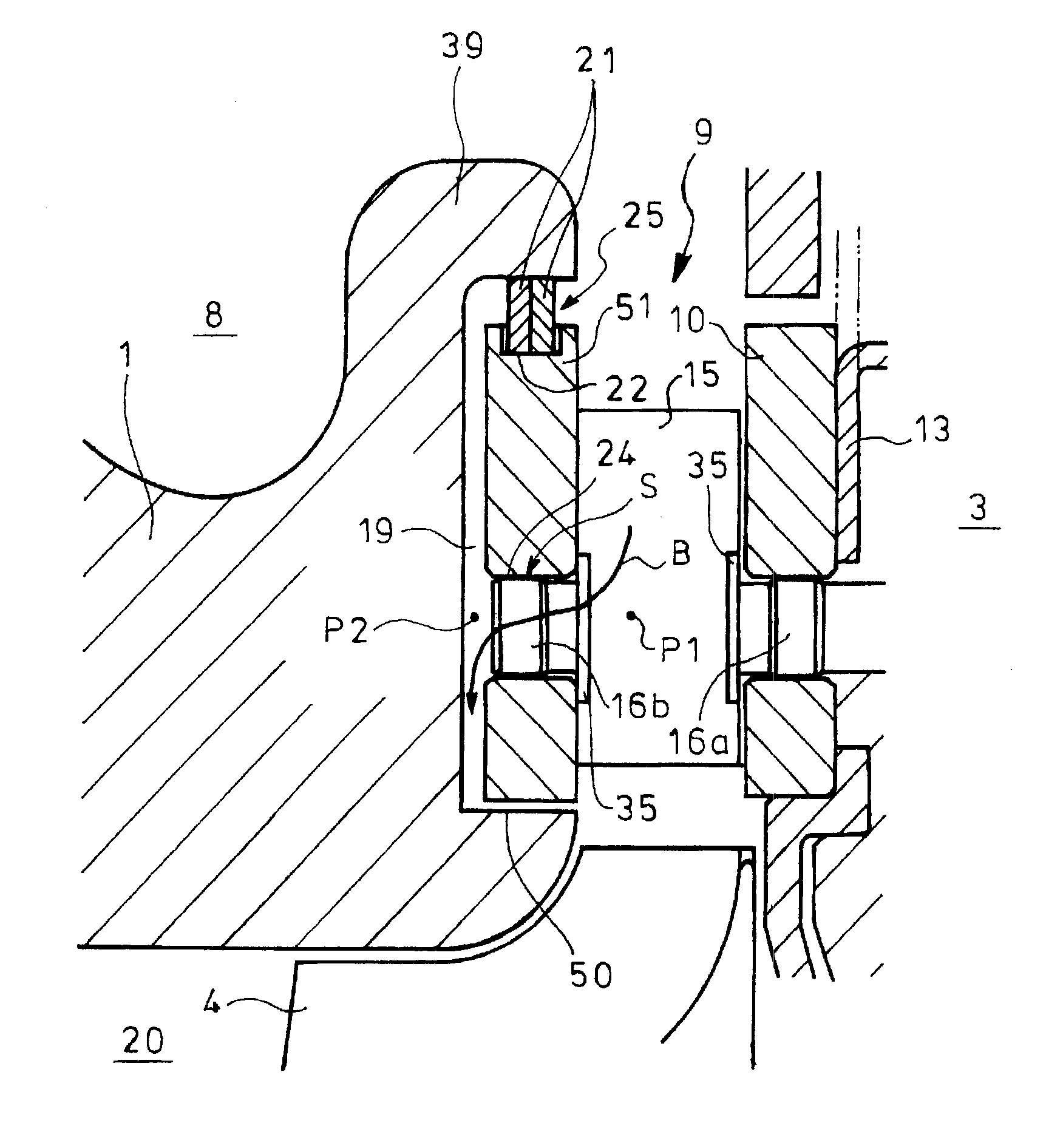

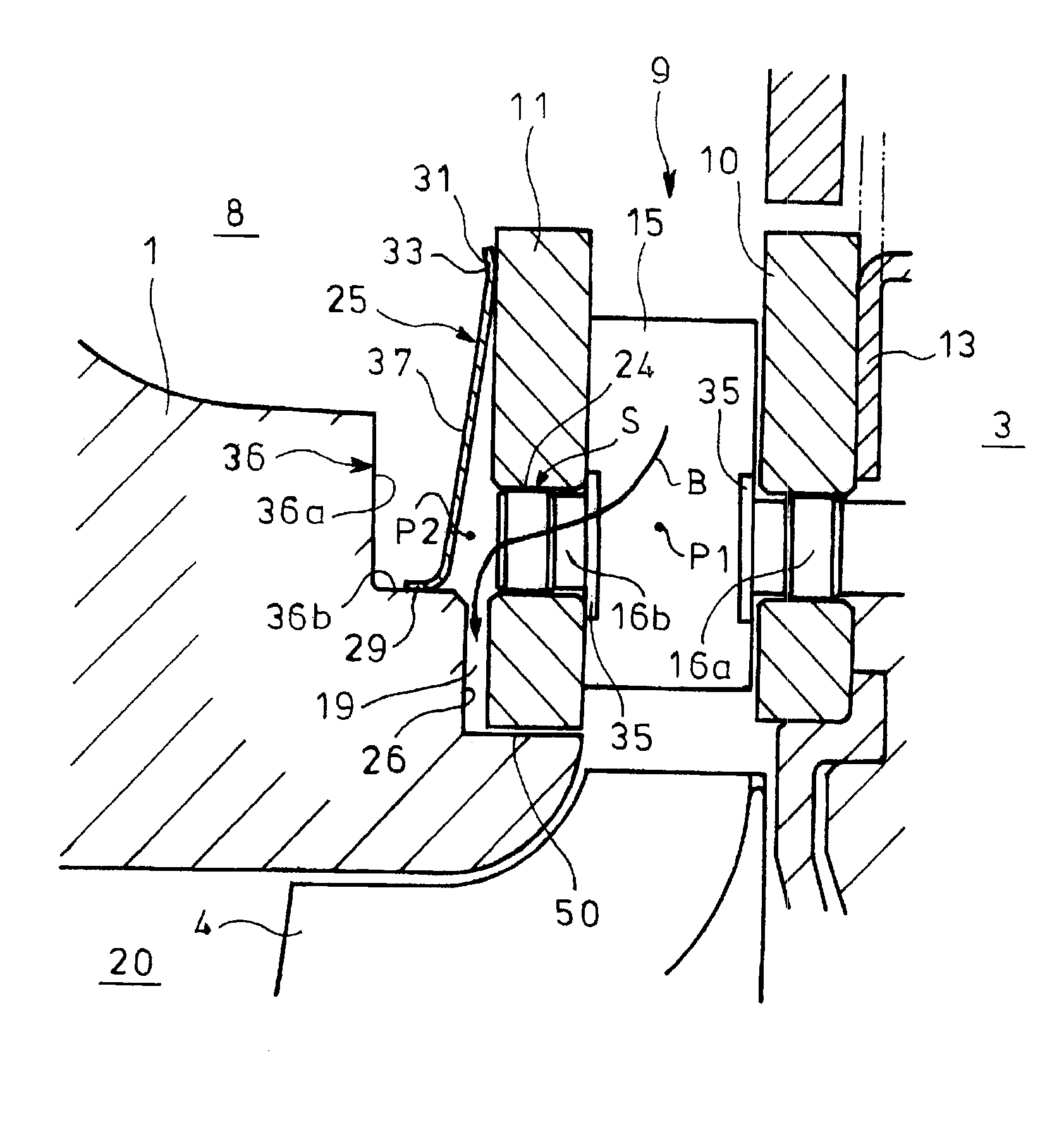

[0038] figure 2 represents an embodiment of the present invention, which will be described in figure 1In the variable capacity turbocharger, the rear exhaust gas introduction wall 11 having the extension part 11' is used as the disc-shaped rear exhaust gas introduction wall 51, whereby the front exhaust gas introduction wall 10 and the rear row The gas introduction walls 51 are each formed in a disc shape. And it is preferable that the disc-shaped rear exhaust gas introduction wall 51 and the disc-shaped front exhaust gas introduction wall 10 are formed of the same material, or are formed of materials having the same coefficient of linear expansion, by which the rear The linear expansion coefficients of the exhaust gas introduction wall 51 and the front exhaust gas introduction wall 10 are equal, so that the vane shafts 16a, 16b fixed on both sides of the nozzle vane...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com