Material penetrating positioning mechanism

A positioning mechanism and material threading technology, applied in positioning devices, metal processing equipment, feeding devices, etc., can solve the problems of half-cutting the material head, unable to see the material head, etc., and achieve the effect of easy material threading

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

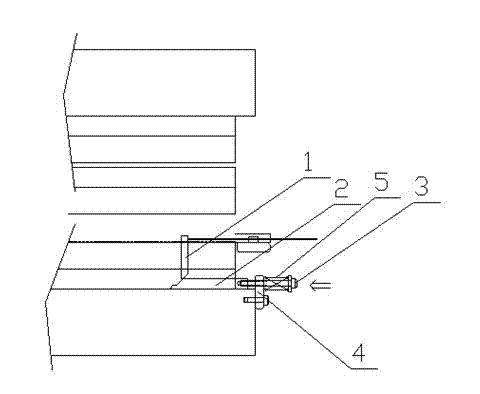

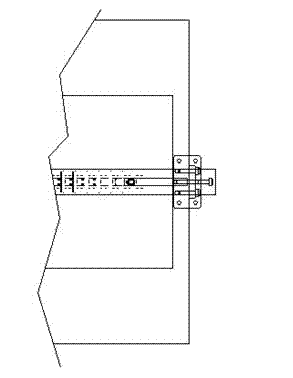

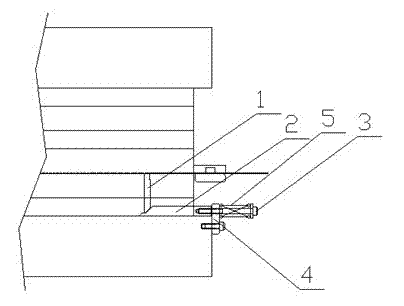

[0016] Embodiment: a material threading positioning mechanism, including a positioning pin 1 located in the lower mold,

[0017] The top block 2 and the driving device, the positioning pin 1 can be slidably inserted in the positioning hole of the lower mold in the longitudinal direction, the lower end of the positioning pin 1 is provided with a first slope, and the top block 2 can be horizontally and linearly slid and positioned in the lower mold, One end of the top block 2 is provided with a second slope matching the first slope at the lower end of the positioning pin 1. The driving device is fixed on the lower die and can drive the top block 2 to slide. In this way, when feeding the material, only the driving device needs to drive the top block 2 Slide inward, the positioning pin 1 is lifted up, workers can easily find the positioning pin 1, accurately set the positioning hole on the material belt on the positioning pin 1, and reset the top block 2 after the material is t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com