High-volume utilization rate fuel tank

A technology with high utilization rate and high volume, which is applied in the direction of liquid fuel feeder, engine components, machine/engine, etc. It can solve the problem of not being able to absorb oil, reduce the inventory, improve the actual utilization rate, and facilitate installation and maintenance Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

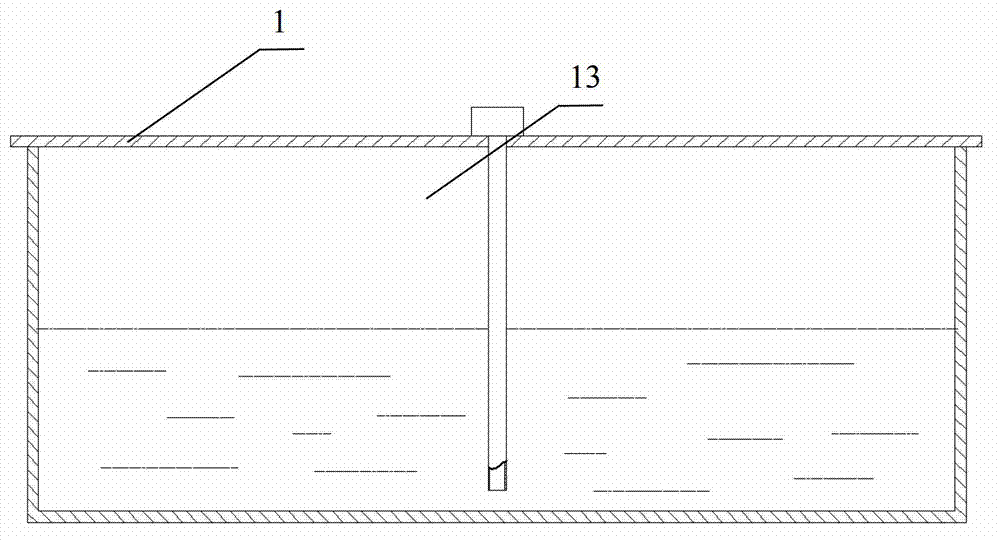

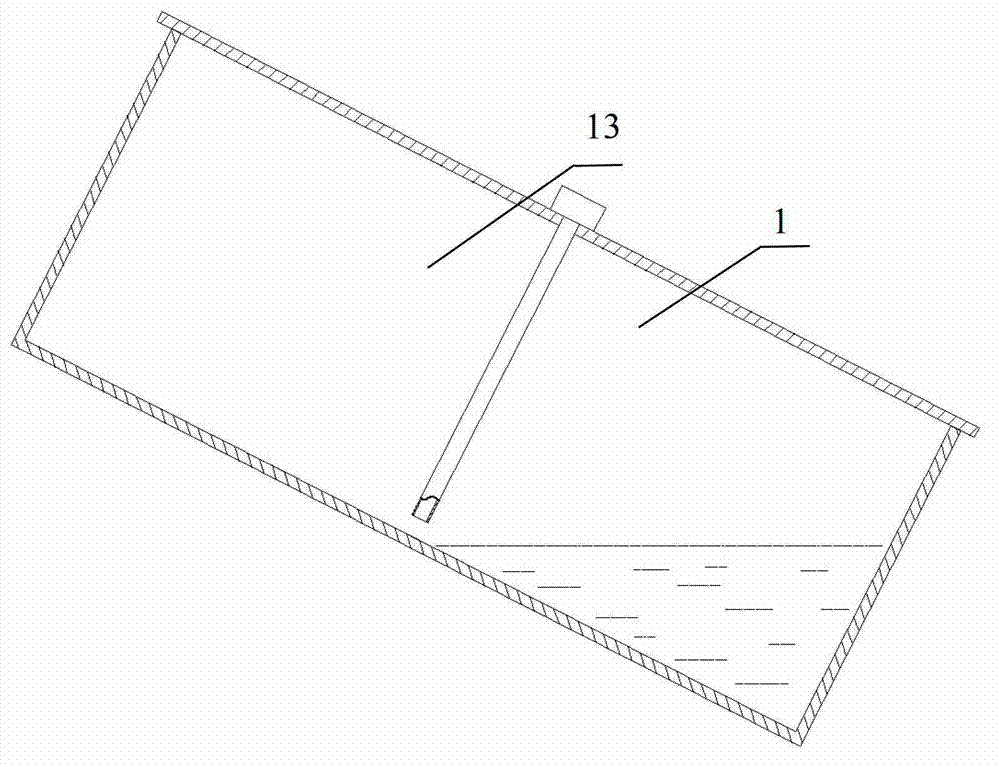

[0029] The specific implementation will be described below in conjunction with the accompanying drawings.

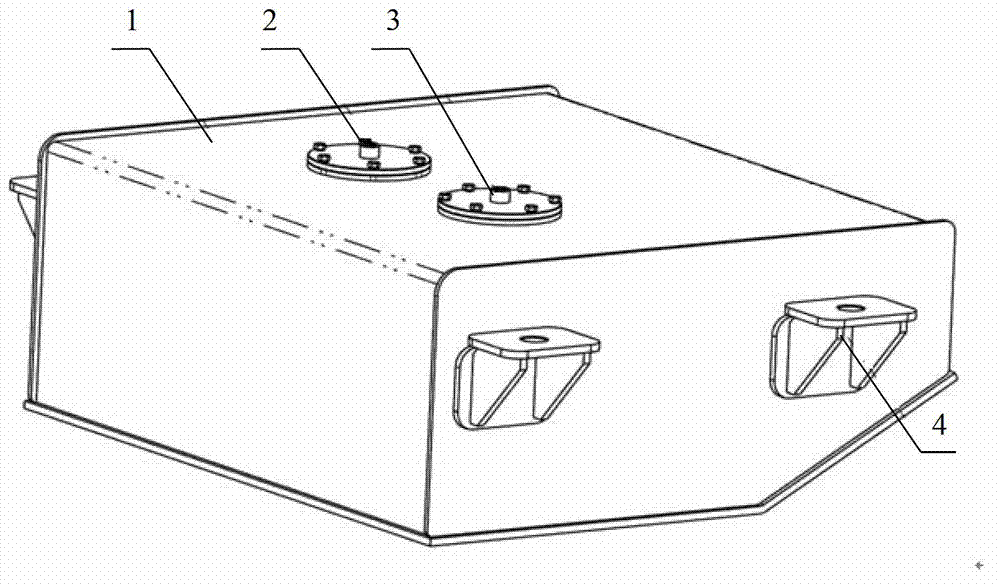

[0030] Figure 3 to Figure 13 A preferred implementation of the present invention is shown, and the implementation of this example can be applied to other construction machinery equipment.

[0031] Such as image 3 , Figure 4 Shown is a rear-mounted diesel tank for a wheel loader. The diesel tank is composed of a tank body 1, an oil suction device 2, an oil return device 3 and a mounting support 4 for the fuel tank. The tank body 1 is an approximately square structure, and its bottom plate is the rear The bending plate is bent upwards at the top, and the bending angle is determined according to the requirements of the departure angle of the whole machine to ensure that the diesel tank is within the envelope of the departure angle of the whole machine. Such as Figure 5 As shown, the oil suction device 2 is composed of an oil suction flange 5, an oil suction joint 12...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com