Asymmetric stator teeth in an electric motor

An asymmetric, stator technology used in motorized assemblies, synchronous motors with stationary armatures and rotating magnets, electromechanical devices, etc. to address performance requirements, packaging constraints imposed by design constraints, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

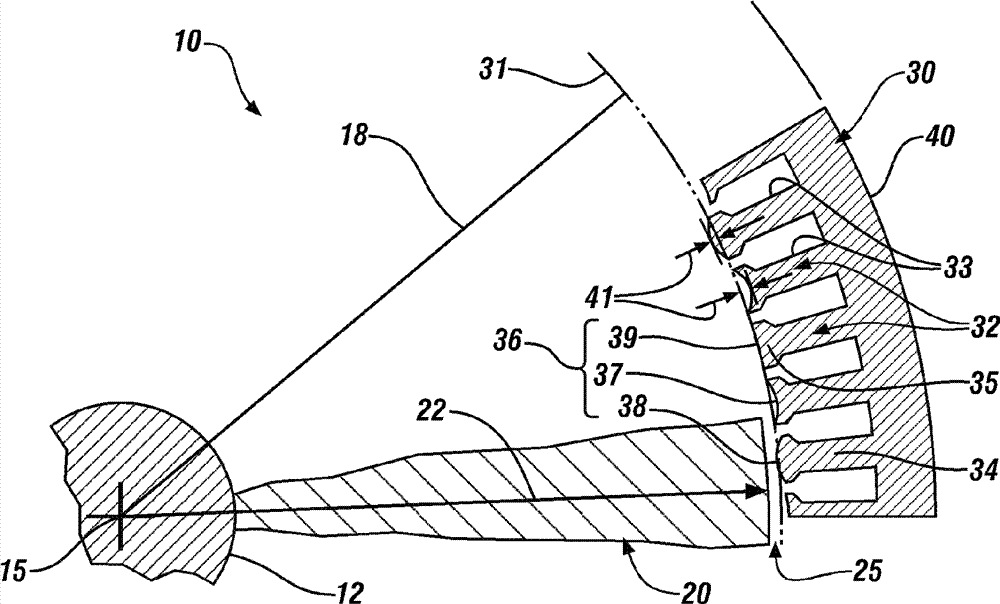

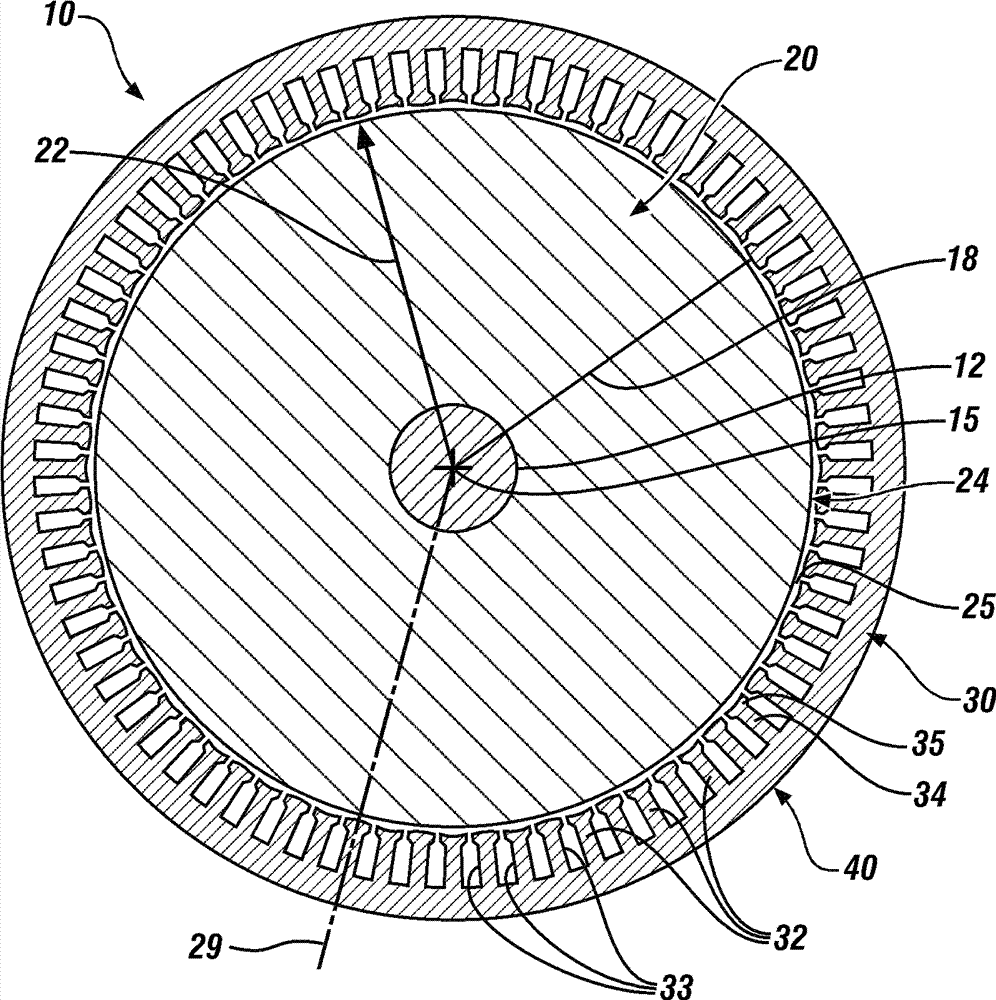

[0014] Referring now to the drawings, which are shown for purposes of illustrating certain exemplary embodiments only and not for purposes of limiting the invention, figure 1 is a cross-sectional view of a permanent magnet electric motor 10 comprising: a rotor 20 mounted on a shaft 12 and inserted into a hollow cylindrical stator 30; figure 2 is a partial sectional view of the permanent magnet electric motor 10 . The permanent magnet electric motor 10 includes a housing with end caps on which a shaft 12 of a rotor 20 is rotatably mounted. The centerline of the shaft 12 defines a longitudinal axis 15 which is the axis of rotation of the rotor 20 and also the longitudinal axis of the stator 30 . The sectional view of the permanent magnet electric motor 10 is shown normal to the longitudinal axis 15 . The salient features of the electric motor are primarily described on the basis of a sectional view perpendicular to the longitudinal axis 15 . A portion of an imaginary circle ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com