Snow melting vehicle

A technology for a snowmobile and a vehicle bucket, applied in the field of snow melting vehicles, can solve the problems of unclean snow removal, increased snow removal cost, inability to remove ice, etc., and achieves the effects of good effect, good snow removal effect, and fast ice and snow removal speed.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

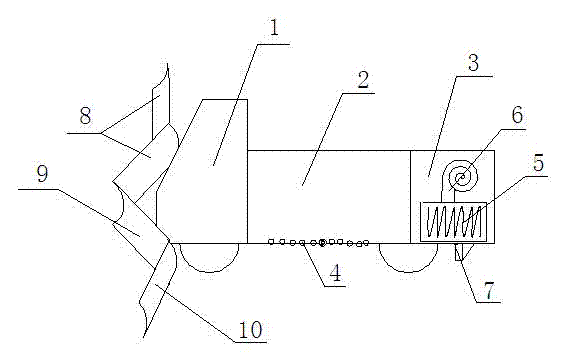

[0011] Accompanying drawing is a kind of specific embodiment of the present invention. This embodiment is a snow melting vehicle, which includes a body 1 with a bucket, and is characterized in that: the bucket includes a front bucket 2 and a rear bucket 3; coarse salt powder is placed in the front bucket 2, and the front bucket 2 The bottom plate of the bucket 2 is uniformly provided with a small hole 4 for salt leakage; the rear bucket 3 is provided with a heating device 5, and the heating device 5 is equipped with a blower device 6, and the heating device 5 is provided at the bottom of the rear bucket 3 Blast toward the hot air outlet 7 on the ground. The front of the car body is provided with a snow removal board 8, and the snow removal board 8 is composed of two arc-shaped inclined plates 9 and an arc-shaped horizontal plate 10, the two arc-shaped inclined plates 9 are V-shaped, and the two arc-shaped inclined plates The included angle between the plates 9 is greater than...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com